Variable-diameter wheel and agricultural vehicle chassis

A wheel and variable technology, applied in the direction of wheels, vehicle parts, control devices, etc., can solve the problems of large volume and heavy weight, and achieve the effect of small volume, high accuracy and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

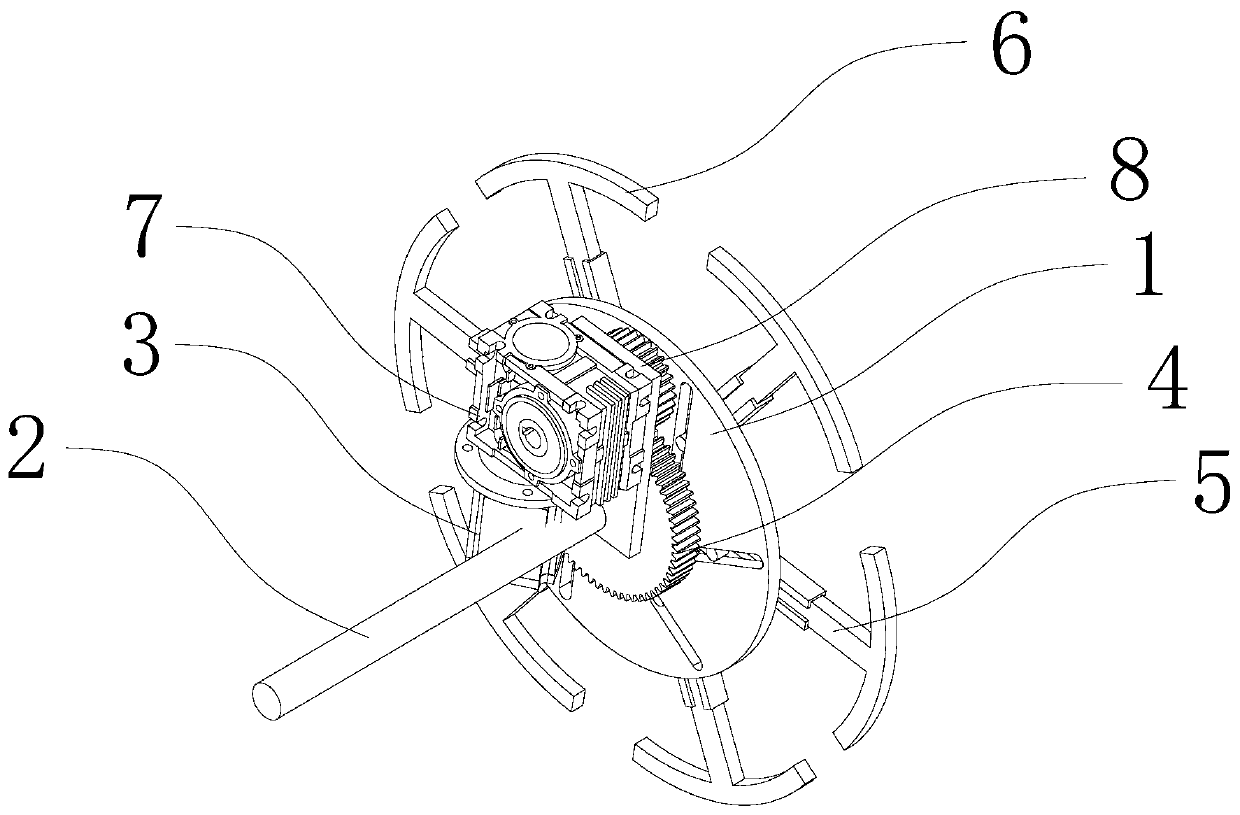

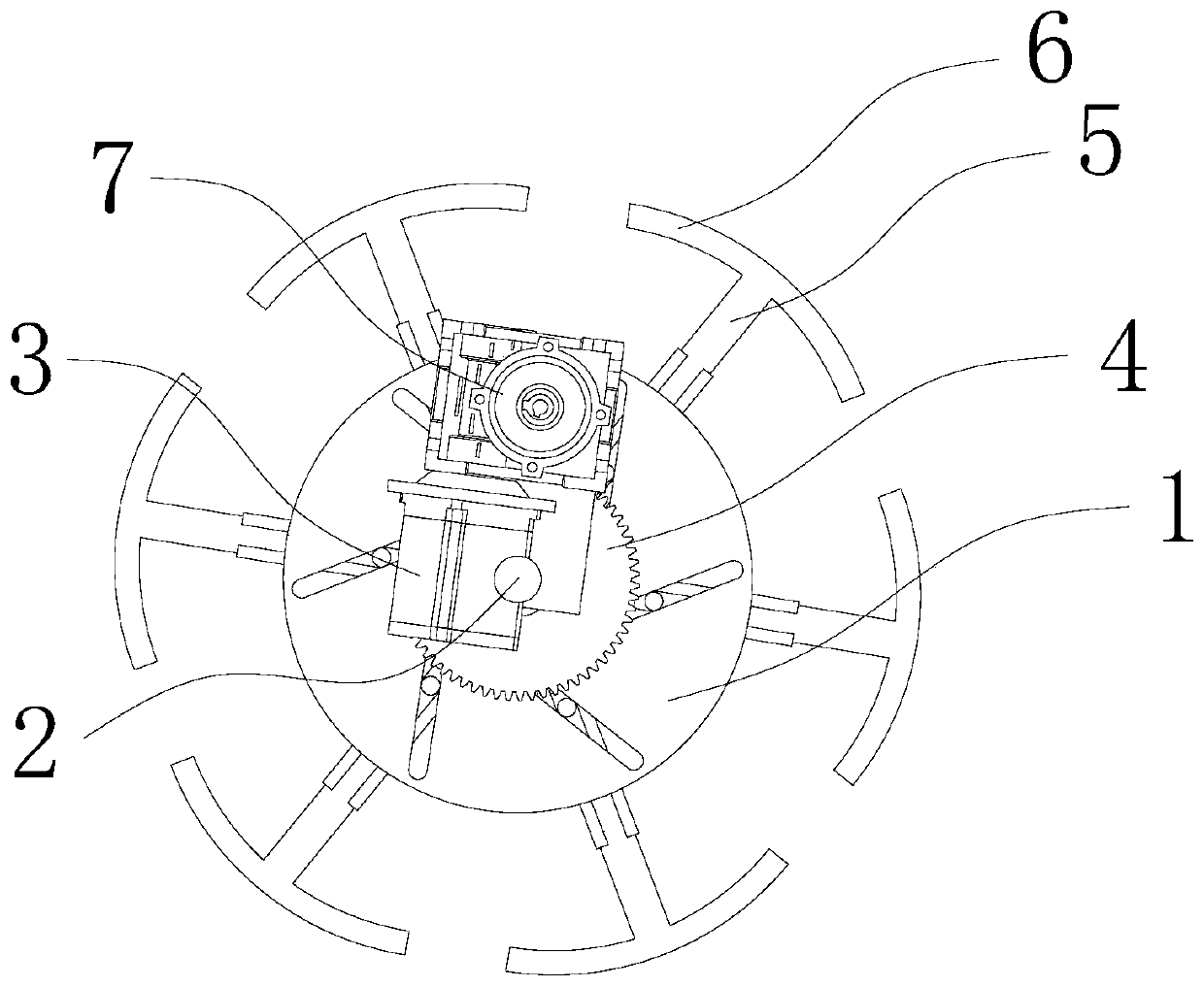

[0043] Such as Figure 1 ~ Figure 3 As shown, the present embodiment provides a variable-diameter wheel, which includes a wheel disc 1, a wheel shaft 2, a stepper motor 2, a gear assembly 3, six sliding mechanisms 4 and six curved tires 5, wherein the wheel shaft 2 A wheel with a keyway.

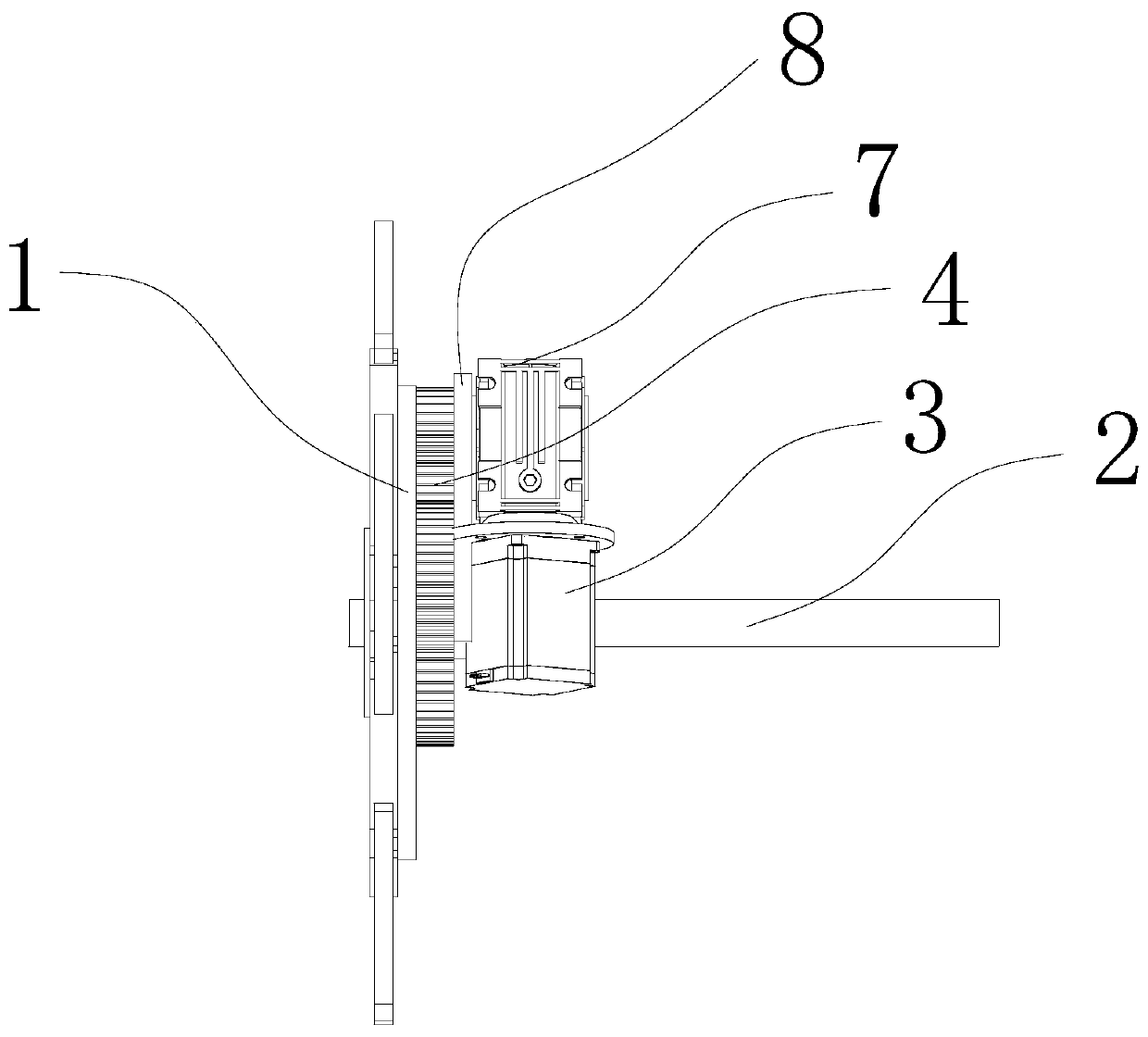

[0044] Such as Figure 4 ~ Figure 7 As shown, the center of the wheel disc 1 is provided with a first through hole 101, and a copper sleeve self-lubricating bearing is provided between the first through hole 101 and the wheel shaft 2, and the gear assembly 4 includes a first gear 401 and a second gear 402 meshed with each other. The center of the second gear 402 is provided with a third through hole 4021, the diameters of the first through hole 101 and the third through hole 4021 are larger than the diameter of the wheel shaft 2, and the wheel shaft 2 passes through the third through hole 4021, the first The through hole 101, the second gear 402 is fixed on the wheel disc 1, the stepping m...

Embodiment 2

[0054] Such as Figure 14 ~ Figure 17 As shown, the present embodiment provides an agricultural vehicle chassis, which can be an orchard transport vehicle, etc., and the chassis includes a frame 10, a first wheel 11, a second wheel 12 and a travel drive mechanism 13; the first wheel 11 One, the first wheel 11 is arranged on the front portion of the frame 8, as the front wheel; the second wheel 12 is two, and each second wheel 10 adopts the variable diameter wheel of the above-mentioned embodiment 1, and the two second wheels Wheel 12 is symmetrically arranged on the rear portion of frame 10, as rear wheel, is connected between the axles of two second wheels 12, and the axle centers of two second wheels 12 coincide; Walking drive mechanism 13 is arranged on machine The frame 10 is used to drive the second wheel 12 to move.

[0055] Further, the travel drive mechanism 13 includes a travel drive motor 1301, a travel drive chain 1302 and a differential 1303, and the travel drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com