Production equipment and preparation process of high-wear-resistance antistatic mine car carriage repairing material

A technology for repairing materials and production equipment, applied in mixers, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of low wear resistance and antistatic properties of repairing materials, and no replacement of stirring heads, etc. To achieve the effect of improving mixing efficiency, convenient replacement, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

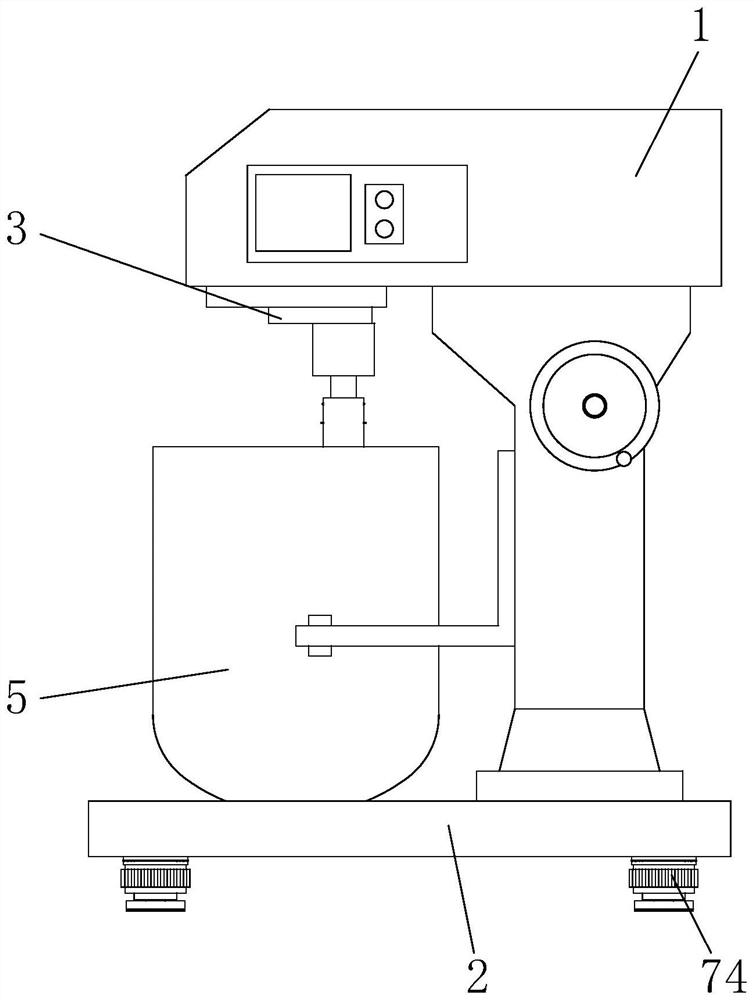

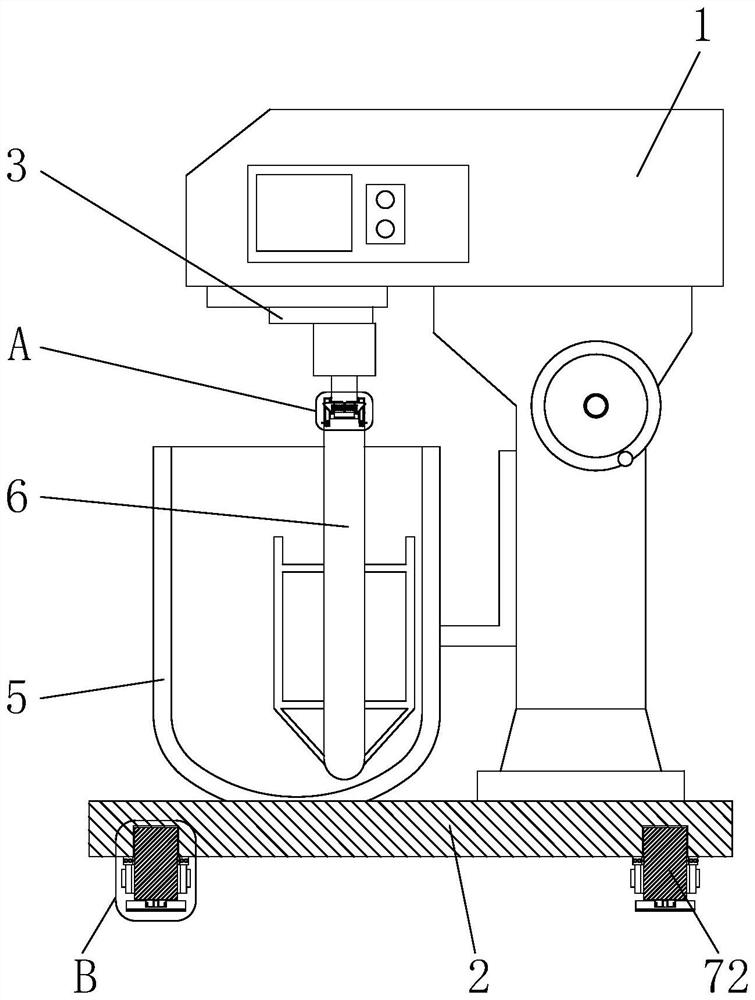

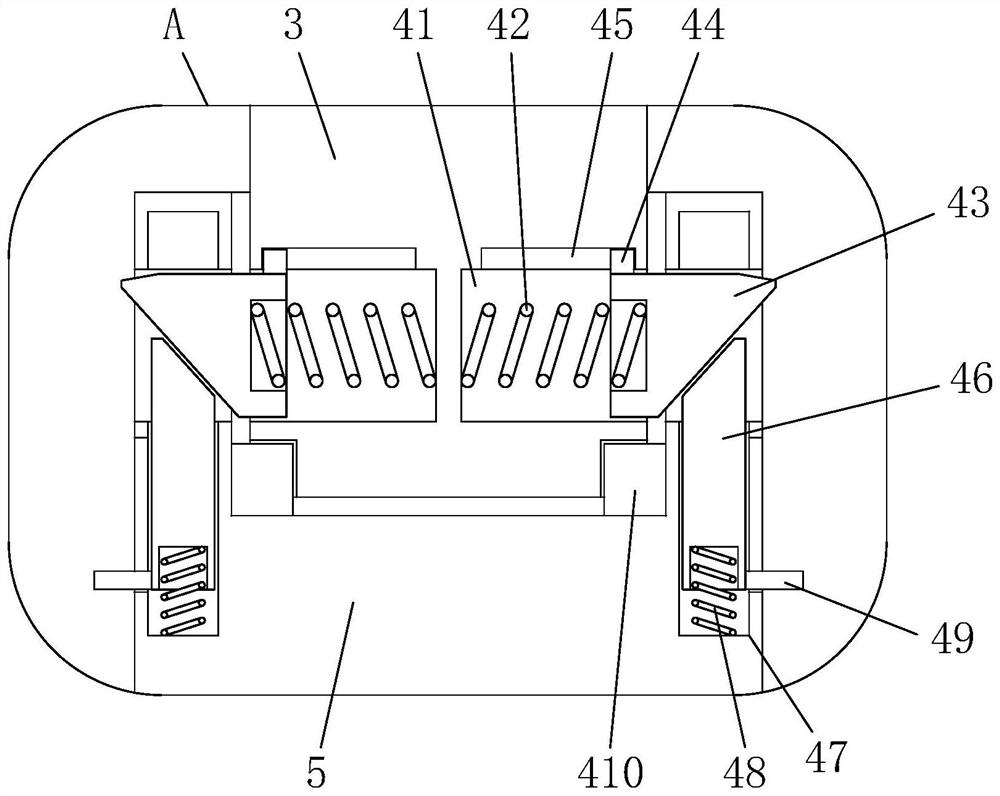

[0031] see Figure 1-6 As shown, a production equipment and preparation process of a high wear-resistant and antistatic mine car repair material, including phosphoric acid, copper oxide, aluminum hydroxide, zirconia, magnesium oxide and a mixing device; the mixing device includes a device main body 1, a base 2. Transmission assembly 3, stirring rod 5 and mixing container 6, the device main body 1 is fixedly connected to the base 2, a transmission assembly 3 is provided on one side of the bottom end of the device main body 1, and the stirring rod 5 is arranged on the transmission assembly 3 The bottom end of the base, the mixing container 6 is arranged on one side of the top of the base 2, a connection mechanism is provided between the stirring rod 5 and the transmission assembly 3, and the connection mechanism includes a connection chamber 41, a connection spring 42, a connection block 43 , a sliding assembly, a release assembly and a positioning block 410, the connecting cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com