Multi-region logistics robot suitable for three-dimensional cultivation of plant factory, platform and operation method

A logistics robot and three-dimensional cultivation technology, applied in the field of intelligent agricultural machinery, can solve the problems that it is difficult to realize the high-efficiency operation requirements of plant factories, cannot meet the logistics requirements of plant factories, and is difficult to meet the aseptic production of plant factories, so as to achieve easy secondary development And the effect of function expansion, good support, and increased chassis weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

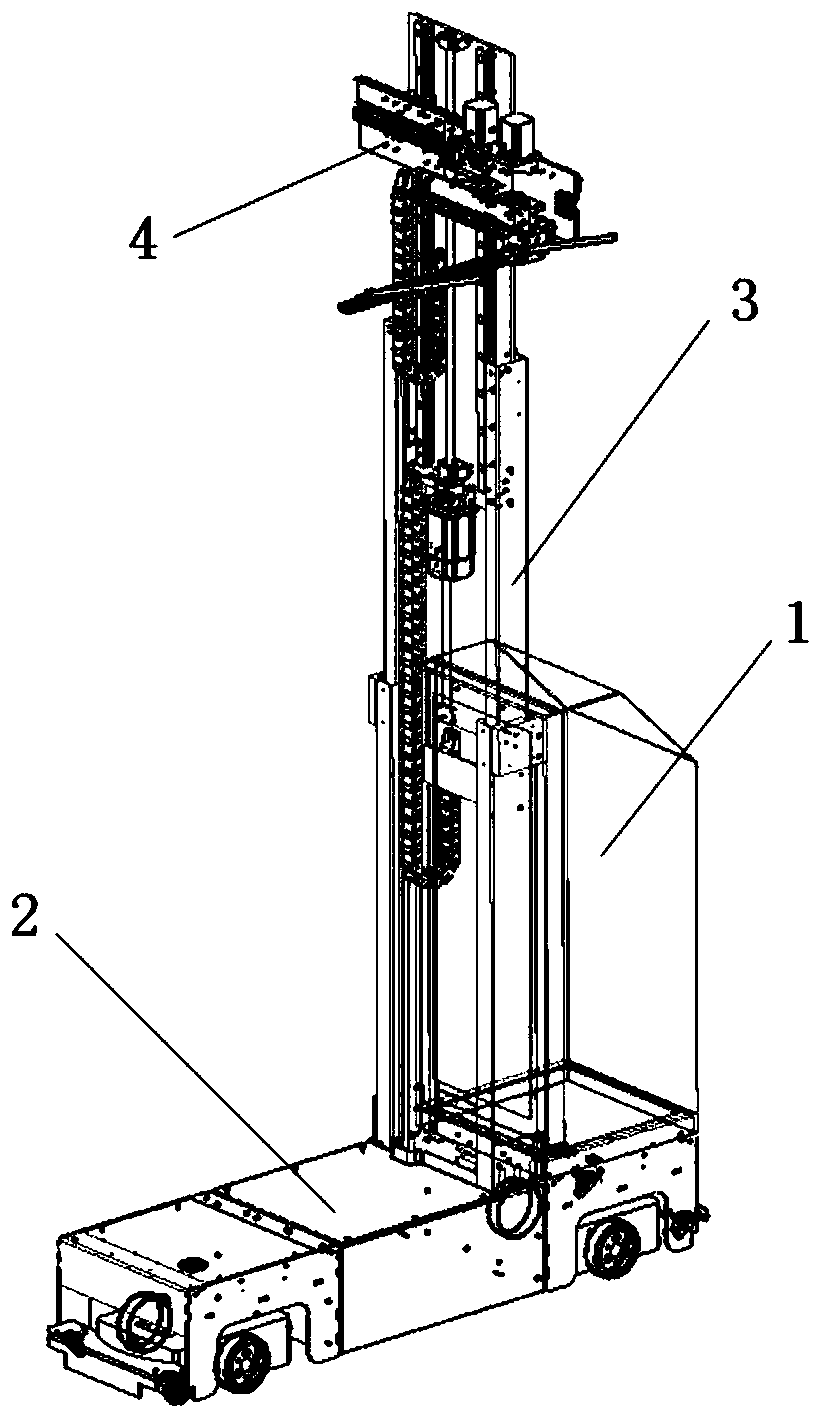

[0060] Such as image 3 As shown, the multi-zone logistics robot platform suitable for plant factory three-dimensional cultivation disclosed by the present invention includes a controller 1, a mobile chassis 2, a lifting device 3 and a translation insertion device 4. The controller is responsible for the movement of the platform and the control of pick-up and handling operations. The mobile chassis includes a navigation and obstacle avoidance device, which is responsible for driving the platform to walk, position and correct deviation according to the preset path. The high-lift lifting device includes a first-level lifting mechanism, a second-level lifting mechanism, a third-level lifting mechanism and a ball screw lifting mechanism. Among them, the first-level lifting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com