A kind of ceramic packaging base material composition and its application

A material composition and ceramic packaging technology, applied in the field of ceramics, can solve the problems of difficult dispersion process, high price, and difficult material acquisition, and achieve the effects of reducing stress failure points, promoting anisotropic growth, and reducing the proportion of liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

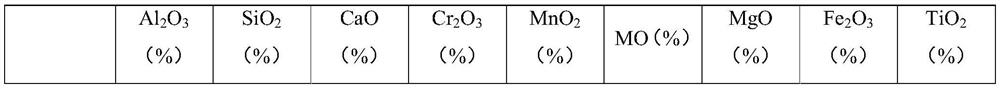

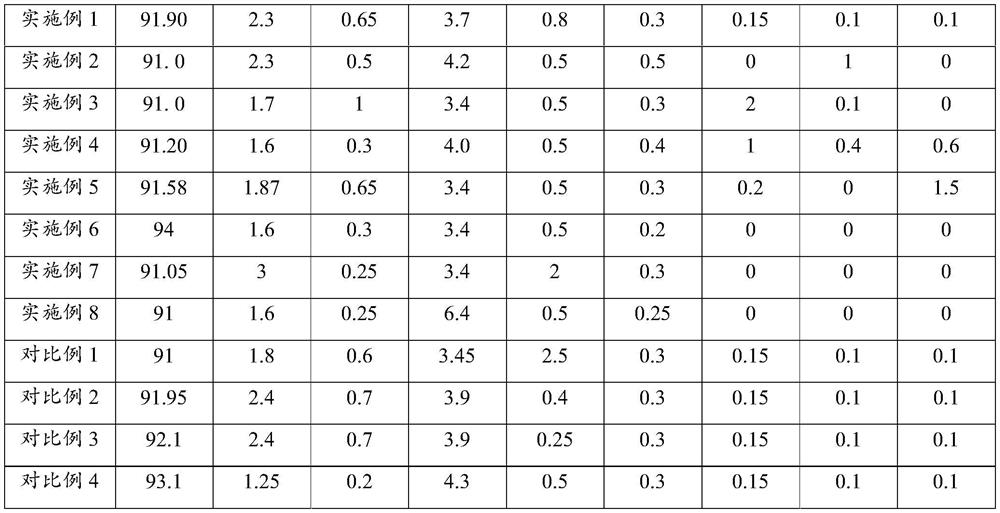

[0027] The mass percent of each component in Examples 1-8 is shown in Table 1.

[0028] The preparation method of Examples 1-8 is as follows: (1) mixing the components contained in the ceramic package base material composition to obtain the ceramic package base material composition;

[0029] (2) uniformly mixing the ceramic packaging base material composition obtained in step (1) with a solvent and a dispersant, then adding resin and a plasticizer and mixing uniformly to obtain a mixture;

[0030] (3) tape-casting the mixture obtained in step (2) to obtain a green body;

[0031] (4) Punching the green body obtained in step (3), filling via holes, stacking and printing metal paste, and then sintering it into porcelain to obtain a ceramic packaging base.

Embodiment 1

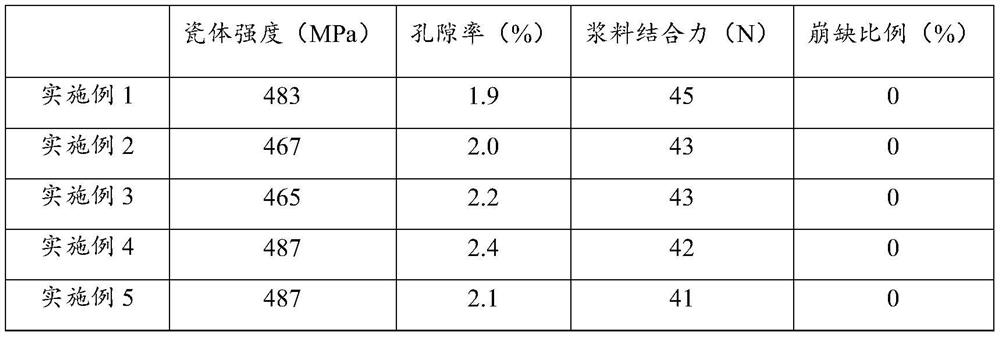

[0048] Example 1 has the best overall performance, and no chipping will occur when the grinding wheel is cut into pieces. That is, when the composition is composed of the following components in mass percentage: 2.3% silicon dioxide, 3.7% chromium trioxide, 0.65% calcium oxide, 0.3% molybdenum, 0.8% manganese dioxide, 0.15% magnesium oxide, three When the ferric oxide is 0.1%, the titanium dioxide is 0.1%, and the aluminum oxide is 91.9%, the overall performance of the prepared ceramic package base is the best, and no chipping will occur when the grinding wheel is cut into slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com