Preparation method of high performance fused silica crucible for polycrystalline silicon ingot casting

A technology of fused silica and fused silica sand, which is applied in the field of preparation of fused silica crucibles for high-performance polycrystalline silicon ingots, can solve problems such as defects and cracks, and achieve reduced defects and cracks, high safety, and high thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0029] A method for preparing a high-performance polysilicon ingot fused silica crucible,

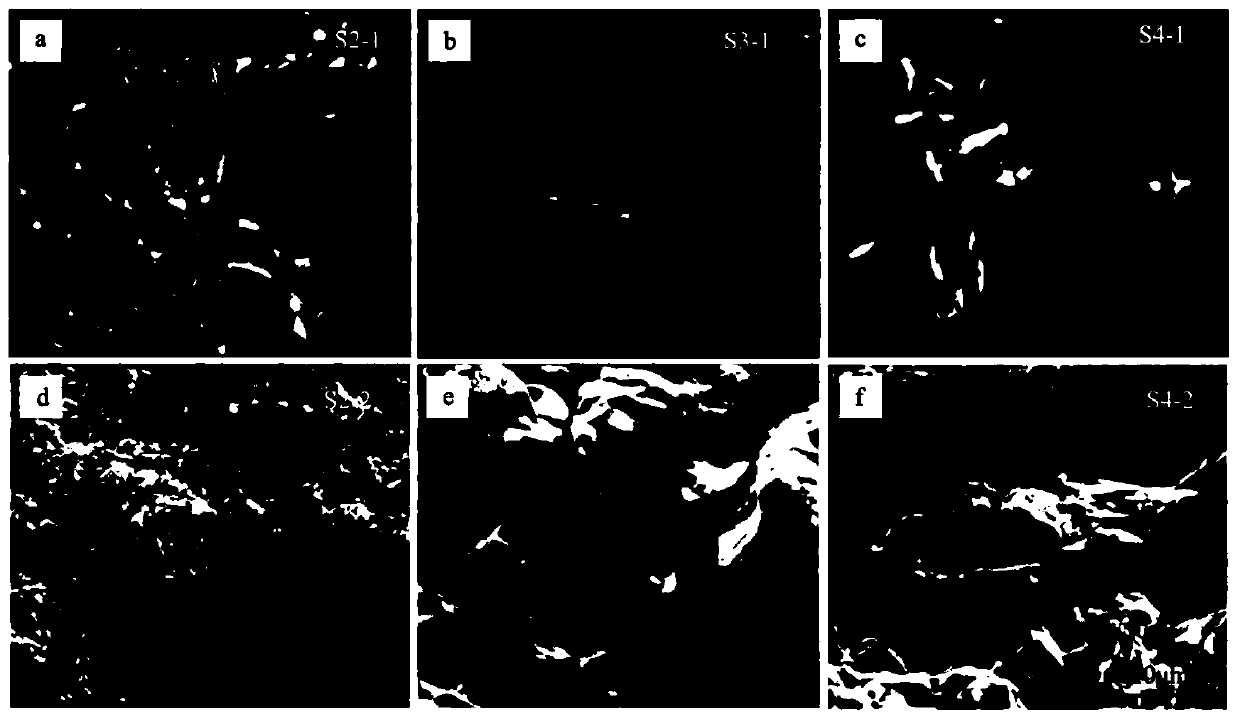

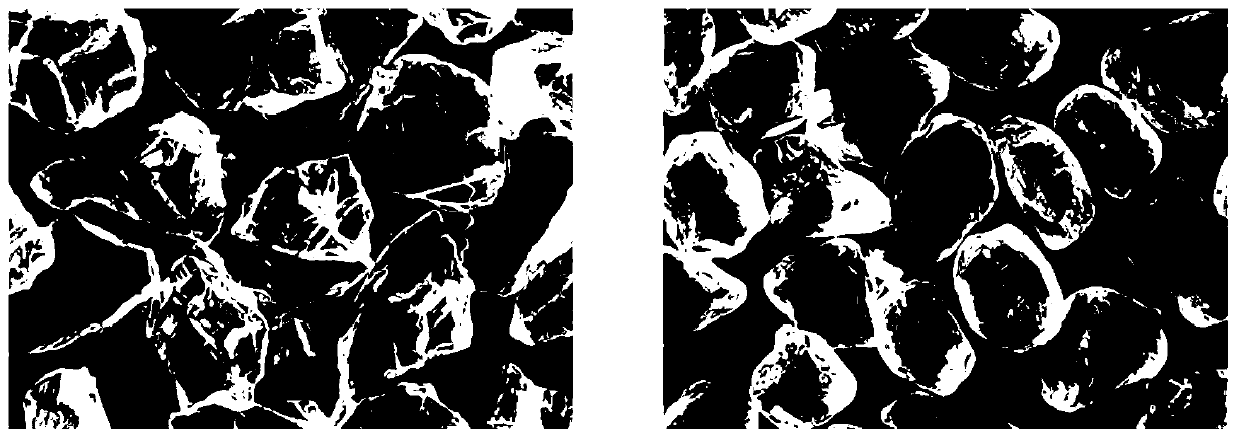

[0030] 1) Prepare fine slurry, which refers to fused silica slurry with a median particle size between 7 and 10 μm. Grind coarse grain fused silica sand (particle size 2~15mm) and fused silica glass frit (irregular shape, size 20~200mm) according to the ratio 1: (0.2~1) and add water, use 1~10t capacity Grind into a fine slurry by a large ball mill. The ball stone materials used for grinding are not limited to alumina and zirconia. The particle size of the ball stone is between 50mm and 150mm, and the water content of the final fine slurry is between 10% and 15%.

[0031] 2) Mix fine slurry and aggregate, add monomer, crosslinking agent and lactic acid during the process. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com