Organic liquid fertilizer production device and process

A technology of organic liquid and production equipment, applied in the field of agricultural material production, can solve problems such as inconsistent original intentions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

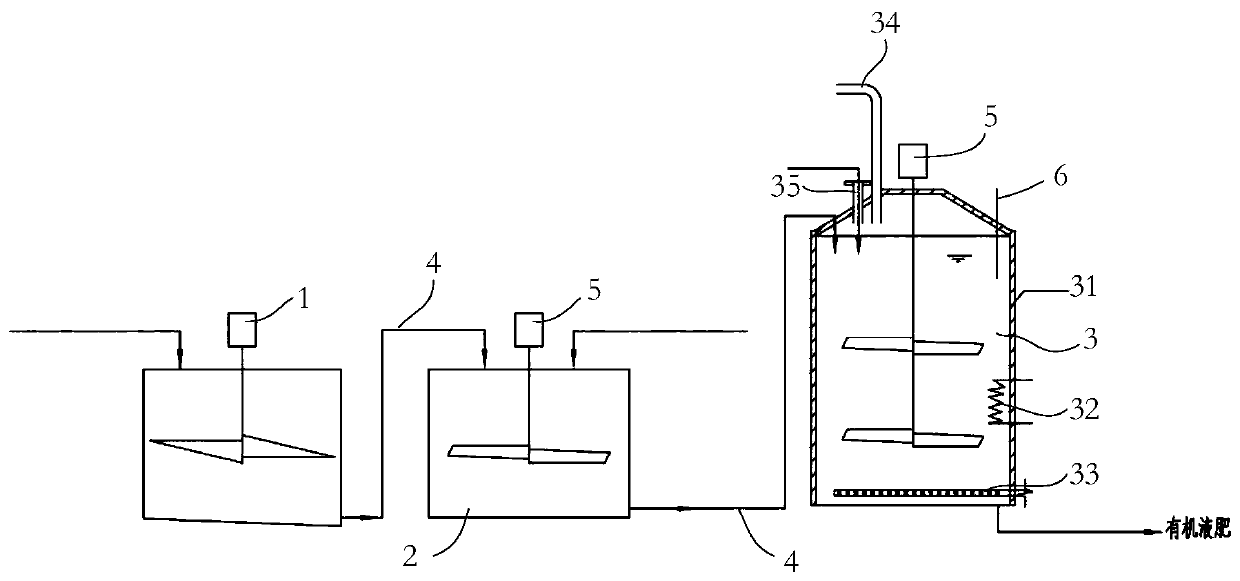

[0036] Such as figure 1 As shown, an organic liquid fertilizer production device in this embodiment includes a pulverizer 1, a blending device 2 and a fermentation device 3, the pulverizer 1 communicates with the blending device 2 through a pipeline 4, and the blending device 2 The fermentation device 3 is communicated with through the pipeline 4; the fermentation device 3 is provided with an insulating layer 31, the top of the fermentation device 3 is provided with a feeding port 34 and an air outlet 35, and an aeration system 33 is installed at the bottom; Stirrers 5 are respectively installed on the blending device 2 and the fermentation device 3 . The aeration system 33 includes an aeration tube evenly arranged at the bottom of the fermentation device 3, and the ventilation rate is 0.2m 3 / m 3 *min. The air outlet is mainly to discharge the excess gas that is introduced into the fermentation device during aeration.

[0037] In this embodiment, by adopting the pulverize...

Embodiment 2

[0047] A kind of technology that adopts embodiment 1 production device to carry out organic liquid fertilizer production of the present embodiment, comprises the following steps:

[0048] S1, adding the raw materials into the pulverizer 1 for pulverization, so that the particle size after pulverization is less than 1 cm;

[0049] S2, pump the pulverized material into the blending device 2, and add aerobic fermentation agent, molasses liquid, biogas slurry or water, adjust the carbon-nitrogen ratio range of the material in the blending device 2 to 25-30, and the solid content 25%-30%, and pumped into the fermentation device 3 after being evenly stirred by the agitator 5 on the deployment device 2; the molasses liquid can be selected from the organic waste water that has produced sucrose;

[0050] S3, the material is subjected to aerobic fermentation in the fermentation device 3, and the fermentation time can be selected for 30-45 days. Fertilizer stabilizers, such as humic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com