Dual-responsive color-changing polylactic acid fiber and preparation and application thereof

A technology of polylactic acid fiber and responsiveness, which is applied in the field of double-responsive color-changing polylactic acid fiber and its preparation and application, can solve the problems of low fiber strength, difficulty in weaving, and changing multiple colors, and achieve wide color selection and color change wide temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

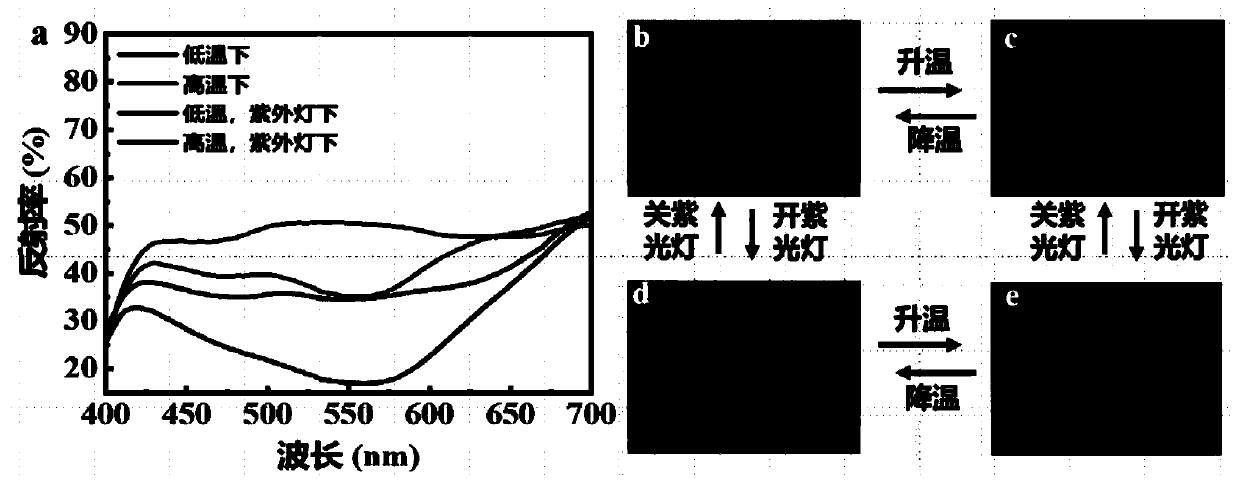

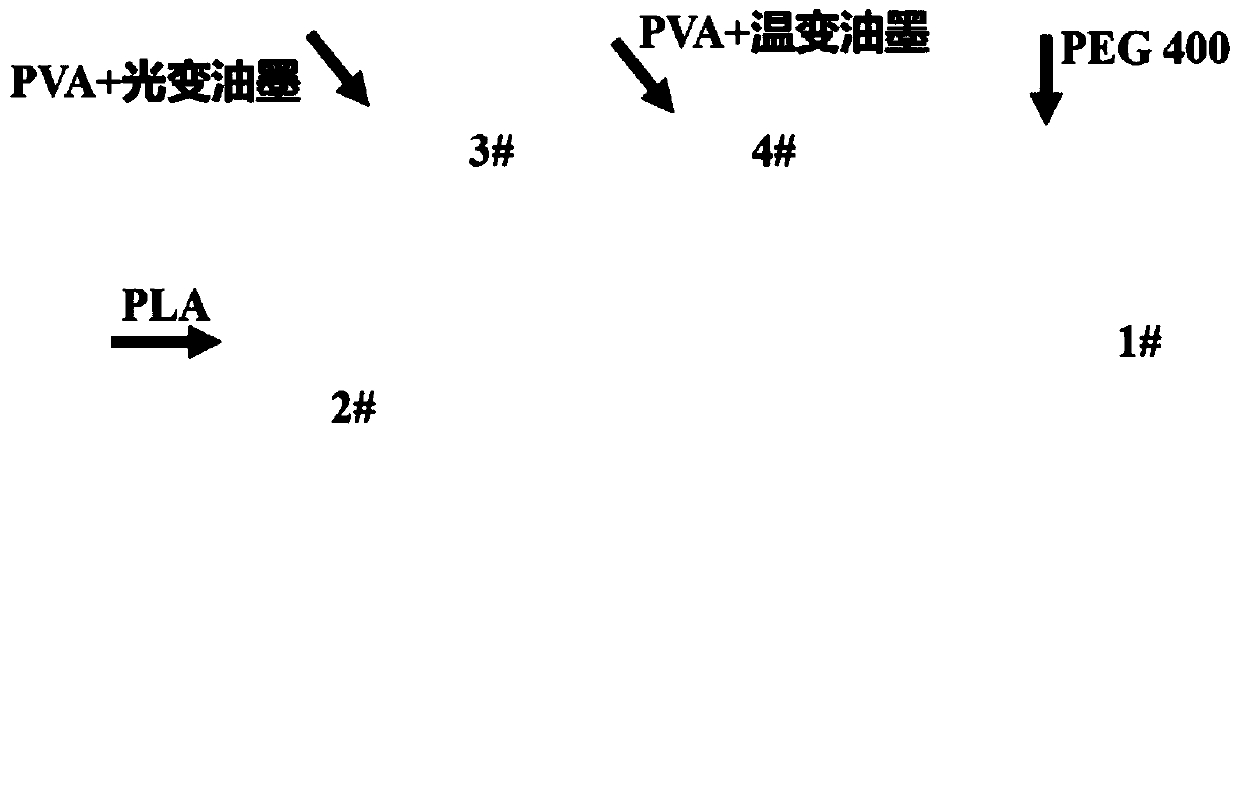

Embodiment 1

[0042] (1) Disperse 25g of polylactic acid particles in 75g of dichloromethane solvent, ultrasonically disperse for 8 hours to obtain a uniform and clear polylactic acid solution, weigh 70mL of polyethylene glycol 400 for later use; weigh under 280-400nm ultraviolet light irradiation Take 3g of ink that changes from white to orange, weigh 3g of ink that turns from black to blue at a heat radiation temperature of 28°C, and disperse the color-changing ink with cold light source (photochromic ink) and the color-changing ink with heat light source (temperature-sensitive color-changing ink) respectively In 92g of deionized water, add 5g of polyvinyl alcohol to the deionized water mixed with cold light source color changing ink (photochromic ink) and hot light source color changing ink (temperature sensitive color changing ink), and ultrasonically disperse for 7 hours to obtain 280-400nm The mixed aqueous solution of ink and polyvinyl alcohol from white to orange under ultraviolet li...

Embodiment 2

[0050] (1) Disperse 22g of polylactic acid particles in 78g of dichloromethane solvent, and obtain a uniform and clear polylactic acid solution by ultrasonication for 8 hours. Weigh 140mL of polyethylene glycol 400 for later use; 5g of the ink that turns yellow, weigh 5g of the ink that turns from purple to pink at a heat radiation temperature of 31°C, and disperse the color-changing ink of cold light source (photochromic ink) and the color-changing ink of heat light source (temperature-sensitive color-changing ink) in 87g respectively. Add 8g of polyvinyl alcohol to deionized water mixed with cold light source color-changing ink (photochromic ink) and hot light source color-changing ink (temperature-sensitive color-changing ink), and ultrasonically disperse for 7 hours to obtain 280-400nm ultraviolet radiation. The mixed aqueous solution of ink and polyvinyl alcohol from white to yellow under the light, and the mixed aqueous solution of ink and polyvinyl alcohol from purple to...

Embodiment 3

[0054] (1) Disperse 20g of polylactic acid particles in 80g of dichloromethane solvent, ultrasonically disperse for 8 hours to obtain a uniform and clear polylactic acid solution, weigh 200mL of polyethylene glycol 400 for later use; weigh under 280-400nm ultraviolet light irradiation Weigh 7g of ink that turns from pink to red, and weigh 7g of ink that turns from gray to blue at a heat radiation temperature of 38°C or higher, and disperse the color-changing ink with cold light source (photochromic ink) and the color-changing ink with heat light source (temperature-sensitive color-changing ink) in 83g of deionized water, and add 10g of polyvinyl alcohol to the deionized water mixed with cold light source color-changing ink (photochromic ink) and hot light source color-changing ink (temperature-sensitive color-changing ink), and ultrasonically disperse for 7 hours to obtain 280-400nm ultraviolet The mixed aqueous solution of ink and polyvinyl alcohol from pink to red under light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com