Color paste color fixing agent for paper, and preparation method and application of color paste color fixing agent

A color fixing agent and color paste technology, which is applied in paper, papermaking, textiles and papermaking, etc., can solve the problem of lack of special color paste color fixing agent, etc., and achieve resistance to papermaking water washing and mechanical interference, small color difference, and increased strength Adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

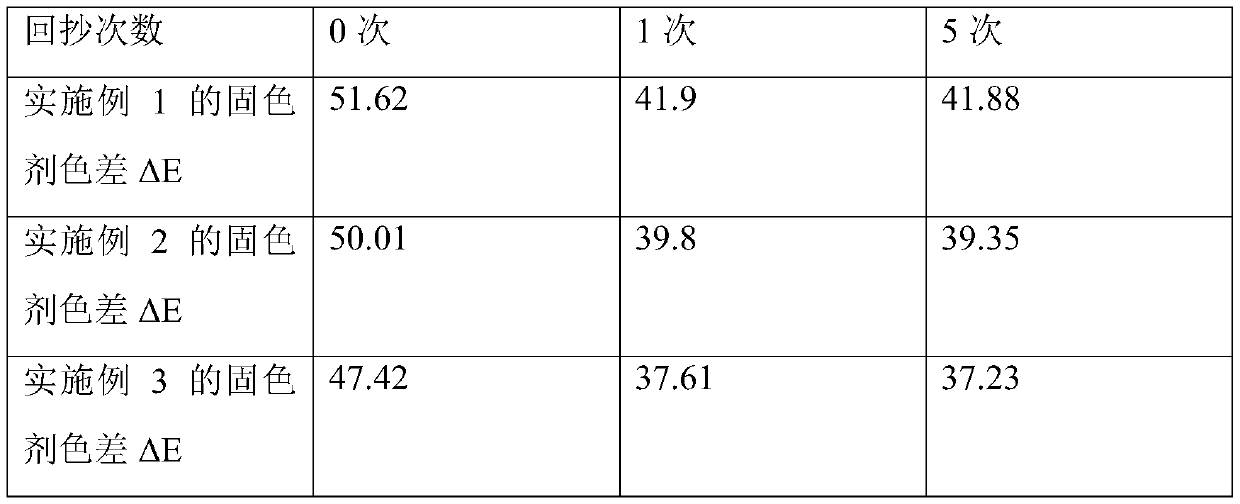

Embodiment 1

[0039] (1) Preparation of color fixing agent:

[0040] 50 parts by mass of water, 10 parts by mass of epichlorohydrin, 5 parts by mass of crosslinking cationic monomer (diethylenetriamine), 1 part by mass of crosslinking accelerator (dimethylamine), 10 parts by mass of hydrophilic adhesive (polyethylene triamine) Vinyl alcohol, PVA205, Japan Kuraray).

[0041] Add epichlorohydrin into the Erlenmeyer flask, and adjust it to be weakly alkaline (pH value is 8) with NaOH, and keep it idling for 30min at a constant temperature of 85°C; and install an adjustable reflux dropper device, add dissolved hydrophilic Adhesive, after 15 minutes of heat preservation, slowly drop the cross-linking cationic monomer and cross-linking accelerator into the Erlenmeyer flask (2 hours); at the same time, raise the temperature to 90°C and stir at a constant temperature for 3 hours, cool down and discharge to obtain a paper color paste Fixative. Adjust the mass concentration of the above-mentioned c...

Embodiment 2

[0047] (1) Preparation of color fixing agent:

[0048] 30 parts by mass of water, 6 parts by mass of epichlorohydrin, 5 parts by mass of crosslinking cationic monomer (diethylenetriamine), 1 part by mass of crosslinking accelerator (dimethylamine), 5 parts by mass of hydrophilic adhesive (carboxylate Methylcellulose QX10, Hercules).

[0049] Add epichlorohydrin into the Erlenmeyer flask, adjust it to be weakly alkaline (pH value is 9) with NaOH, and keep it idling for 30 minutes at a constant temperature of 85°C; install an adjustable reflux dropper device, and add dissolved hydrophilic Adhesive, after 15 minutes of heat preservation, slowly drop the cross-linking cationic monomer and cross-linking accelerator into the Erlenmeyer flask (2 hours); at the same time, raise the temperature to 90°C and stir at a constant temperature for 3 hours, cool down and discharge to obtain a paper color paste Fixative. Adjust the mass concentration of the above-mentioned color-fixing agent ...

Embodiment 3

[0054] (1) Preparation of color fixing agent:

[0055] 50 parts by mass of water, 10 parts by mass of epichlorohydrin, 1 part by mass of a crosslinking cationic monomer (diethylenetriamine), 0.5 parts by mass of a crosslinking accelerator (dimethylamine), 10 parts by mass of a hydrophilic adhesive (polyethylene triamine) Acrylamide, Eisen anionic polyacrylamide).

[0056] Add epichlorohydrin into the Erlenmeyer flask, adjust it to be weakly alkaline (pH value is 9) with NaOH, and keep it idling for 30 minutes at a constant temperature of 85°C; install an adjustable reflux dropper device, and add dissolved hydrophilic Adhesive, after 15 minutes of heat preservation, slowly drop the cross-linking cationic monomer and cross-linking accelerator into the Erlenmeyer flask (2 hours); at the same time, raise the temperature to 90°C and stir at a constant temperature for 3 hours, cool down and discharge to obtain a paper color paste Fixative. Adjust the mass concentration of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com