Drawer type low-melting-point metal high-flux melting device

A drawer-type, high-throughput technology, used in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of large equipment footprint, difficulty in high-throughput preparation, and low production efficiency, and achieve a small footprint. , the structure is simple, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

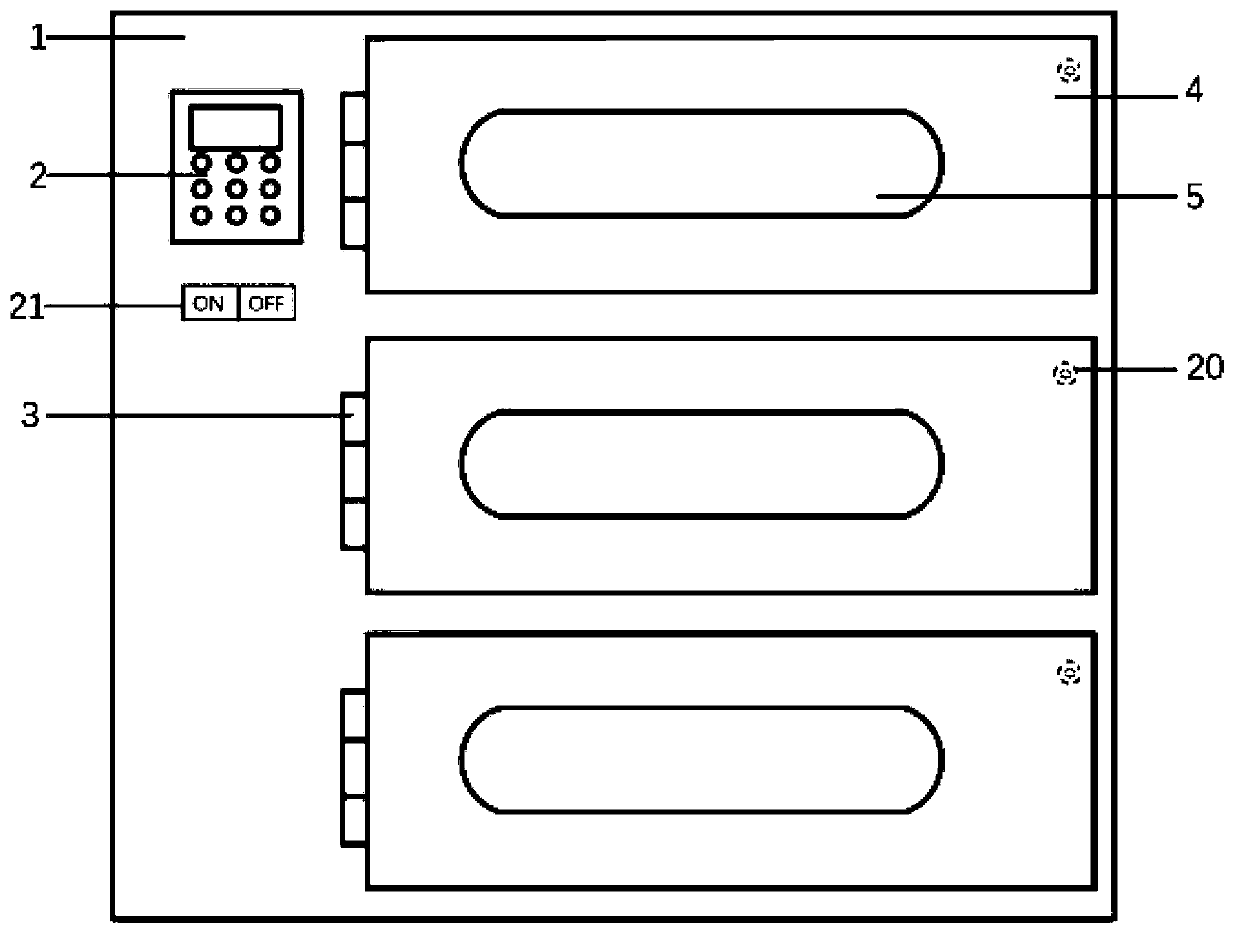

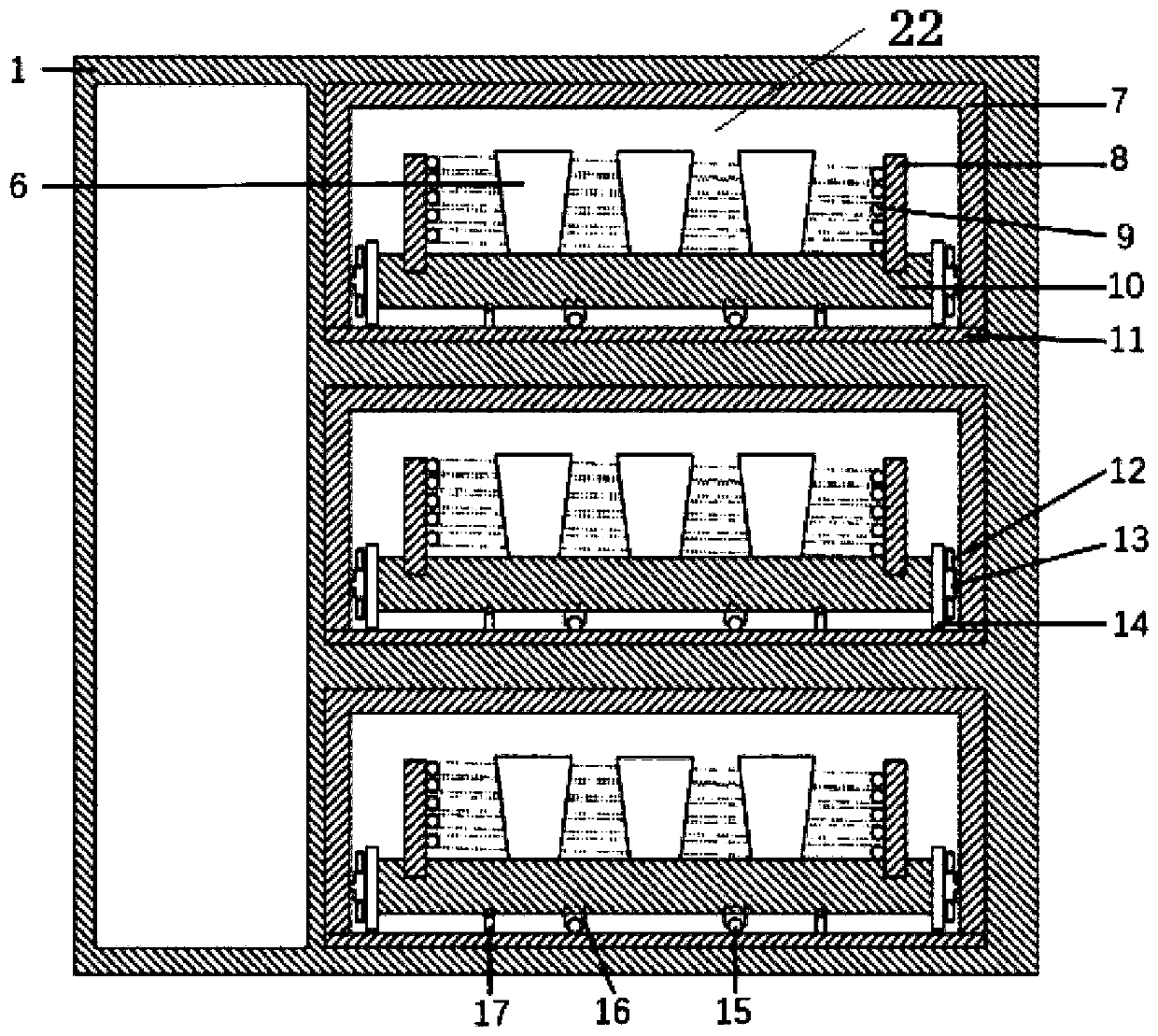

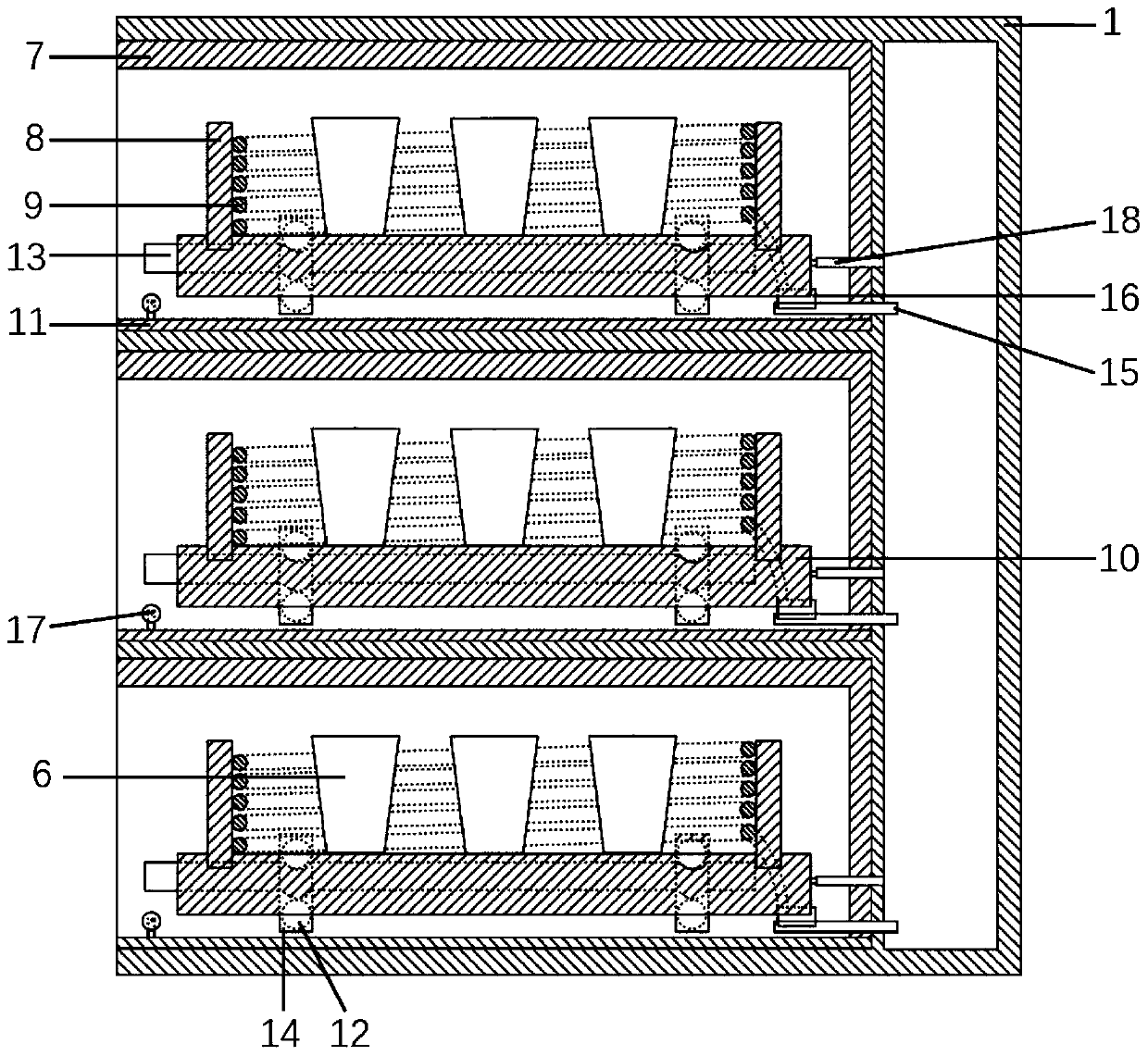

[0030] A drawer-type high-throughput melting device (such as Figure 1-10shown), including intermediate frequency induction melting furnace body 1, control module 2, furnace door hinge 3, furnace door 4, glass observation window 5, crucible 6, insulation layer 7, induction coil support 8, induction coil 9, drawer tray 10. Furnace bottom plate 11, pulley 12, slide rail 13, pulley bracket 14, wire 15, graphite contact 16, support pulley 17, travel switch Ⅰ18, refractory brick 19, travel switch Ⅱ20, main switch 21, movable furnace 22; The furnace body 1 of the intermediate frequency induction melting furnace is equipped with a control module 2 and a main switch 21. There are 3 furnace chambers in the furnace body 1 of the intermediate frequency induction melting furnace. The movable furnace 22 is placed in the furnace chamber. The insulation layer 7 and the furnace floor Composed of 11, the drawer tray 10 is located in the movable furnace 22; the side walls of the movable furnace...

specific Embodiment approach 1

[0034] In this embodiment, three crucibles are placed on each layer, and all the Sn-9Zn-1Bi powders are added to the three crucibles on the first layer. The powder in each crucible is 100ml, and all the three crucibles on the second layer are added Sn-9Zn-2Cu powder, the powder in each crucible is 100ml, add Sn-9Zn-3Ag powder to all the three crucibles on the third layer, the powder in each crucible is 100ml; push the tray into Designate the position and close the furnace door, heat until the samples of each layer reach a molten state, after holding for a certain period of time, each layer is taken out and poured separately, and the melting is completed, and finally Sn-9Zn-1Bi block, Sn-9Zn-2Cu block, The Sn-9Zn-3Ag block realizes the high-throughput preparation of the tin-zinc alloy block.

specific Embodiment approach 2

[0036] In this embodiment, 5 crucibles are placed on each layer, and 5 kinds of powders of Sn-5Zn, Sn-10Zn, Sn-20Zn, Sn-30Zn, and Sn-50Zn are respectively added to the 5 crucibles of the first layer. Put 100ml of powder in each, and add 5 kinds of powders of Sn-4Bi, Sn-8Bi, Sn-18Bi, Sn-30Bi, and Sn-60Bi into the 5 crucibles on the second floor, and place 100ml of powder in each crucible , 5 kinds of powders of Sn-3Zn-7Bi, Sn-6Zn-10Bi, Sn-10Zn-18Bi, Sn-17Zn-15Bi, Sn-30Zn-40Bi were placed in the 5 crucibles of the third layer, respectively. Place 100ml of powder, push the tray to the designated position and close the furnace door, heat each layer separately until the samples of each layer reach a molten state, after holding for a certain period of time, pull out each layer and pour them separately, the melting is completed, and finally the composition and ingredients are obtained All different tin alloy bulks realize the high-throughput preparation of tin alloy bulks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com