Process control test method and system, readable storage medium and electronic equipment

A technology of process control and test method, which is applied in the direction of faulty hardware test method, measurement of electricity, measurement of electrical variables, etc., can solve problems such as inflexibility and long test time, so as to improve production capacity, save pressure test time, facilitate follow-up tests and The effect of shipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

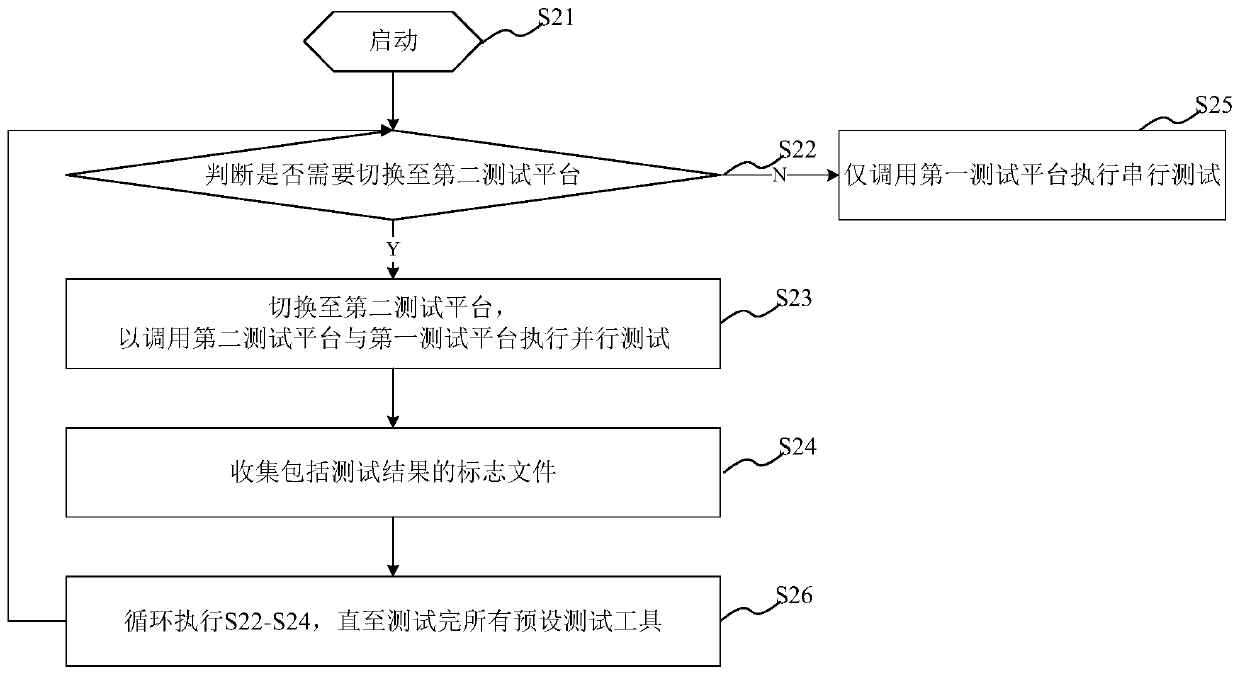

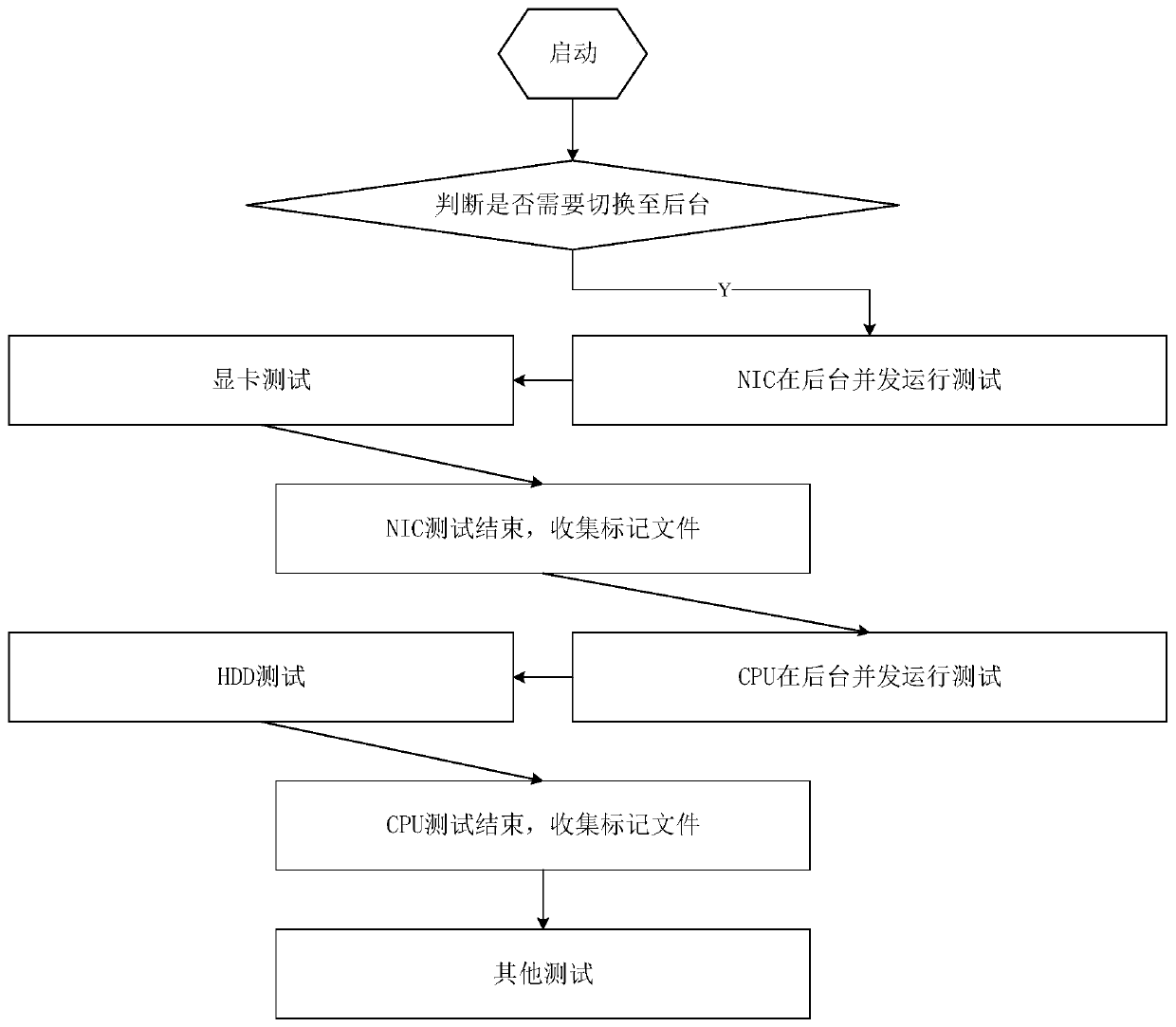

[0029] This embodiment provides a test method for process control, which is adapted to an electronic device, and the electronic device is configured with a first test platform for serial testing and a second test platform for parallel testing; the test method for process control include:

[0030] After entering the test process, judge whether it is necessary to switch to the second test platform according to the test parameters in the preset test tool; if so, switch to the second test platform to call the second test platform and the The first test platform executes the parallel test; after the test is finished, collects the flag file including the test result; if not, only calls the first test platform to execute the serial test.

[0031] The process control testing method provided by this embodiment will be described in detail below with reference to the illustrations. The test method of process control described in this embodiment is used for testing electronic equipment, ...

Embodiment 2

[0081] This embodiment provides a test system for process control, which is adapted to an electronic device, and the electronic device is configured with a first test platform for serial testing and a second test platform for parallel testing; the test system for process control include:

[0082] The judging module is used to judge whether it is necessary to switch to the second test platform according to the test parameters in the preset test tool after entering the test process; if so, switch to the second test platform through a calling module to call the Described second test platform and described first test platform execute parallel test; Wait for test to finish, collect the sign file that comprises test result by a collection module; If not, call described first test platform by described calling module and execute serial test.

[0083] The test system for process control described in this embodiment will be described in detail below with reference to figures. The pro...

Embodiment 3

[0095] This embodiment provides an electronic device, please refer to Figure 4 , shown as a schematic diagram of the hardware structure of the electronic device. like Figure 4 As shown, the electronic device 4 includes: a processor 41, a memory 42, a transceiver 43, a communication interface 44 or / and a system bus 45; the memory 42 and the communication interface 44 are connected to the processor 41 and the transceiver 43 through the system bus 45 And to complete mutual communication, the memory 42 is used to store computer programs, the communication interface 44 is used to communicate with other devices, the processor 41 and the transceiver 43 are used to run the computer programs, so that the electronic device 4 executes the computer program as described in the first embodiment. The individual steps of the test method for process control.

[0096] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com