Suspension gap visual detection method based on image processing

An image processing and visual inspection technology, applied in the field of magnetic levitation technology and image processing, can solve the problems of measurement accuracy, surface roughness, susceptibility to interference, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

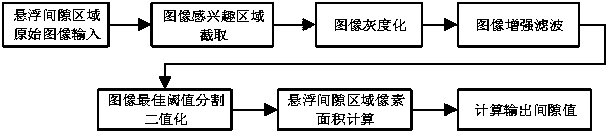

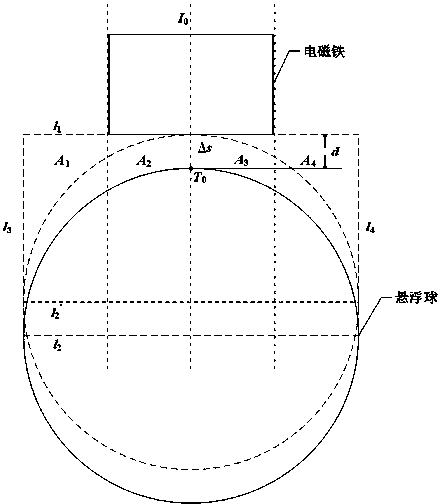

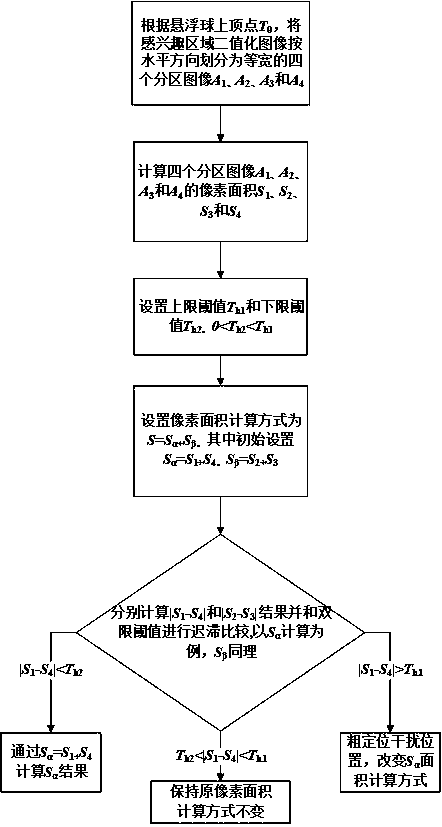

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The present invention collects high-definition images of the suspension gap area in real time through a high-speed industrial camera, and calculates the pixel area of the area of interest in the suspension gap to obtain the corresponding actual suspension gap distance according to the binarized image of the area of interest in the suspension gap after image processing. High-precision measurement of suspension clearance.

[0051] In order to reduce the difficulty of post-image processing and further improve the accuracy of gap measurement, this embodiment requires the selection of foreground objects and backgrounds with color contrast to make the contrast between the measurement background and foreground objects more prominent, while ensuring that the electromagnets and background objects in the foreground objects The levitation ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com