Liquid lead bismuth alloy-inert gas two-phase flow void fraction measuring device and method based on differential pressure method

A liquid lead-bismuth alloy, inert gas technology, applied in the direction of reducing greenhouse gases, climate sustainability, nuclear reactor monitoring, etc., can solve the problems of high operating temperature, flow influence, opacity, etc. Easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail:

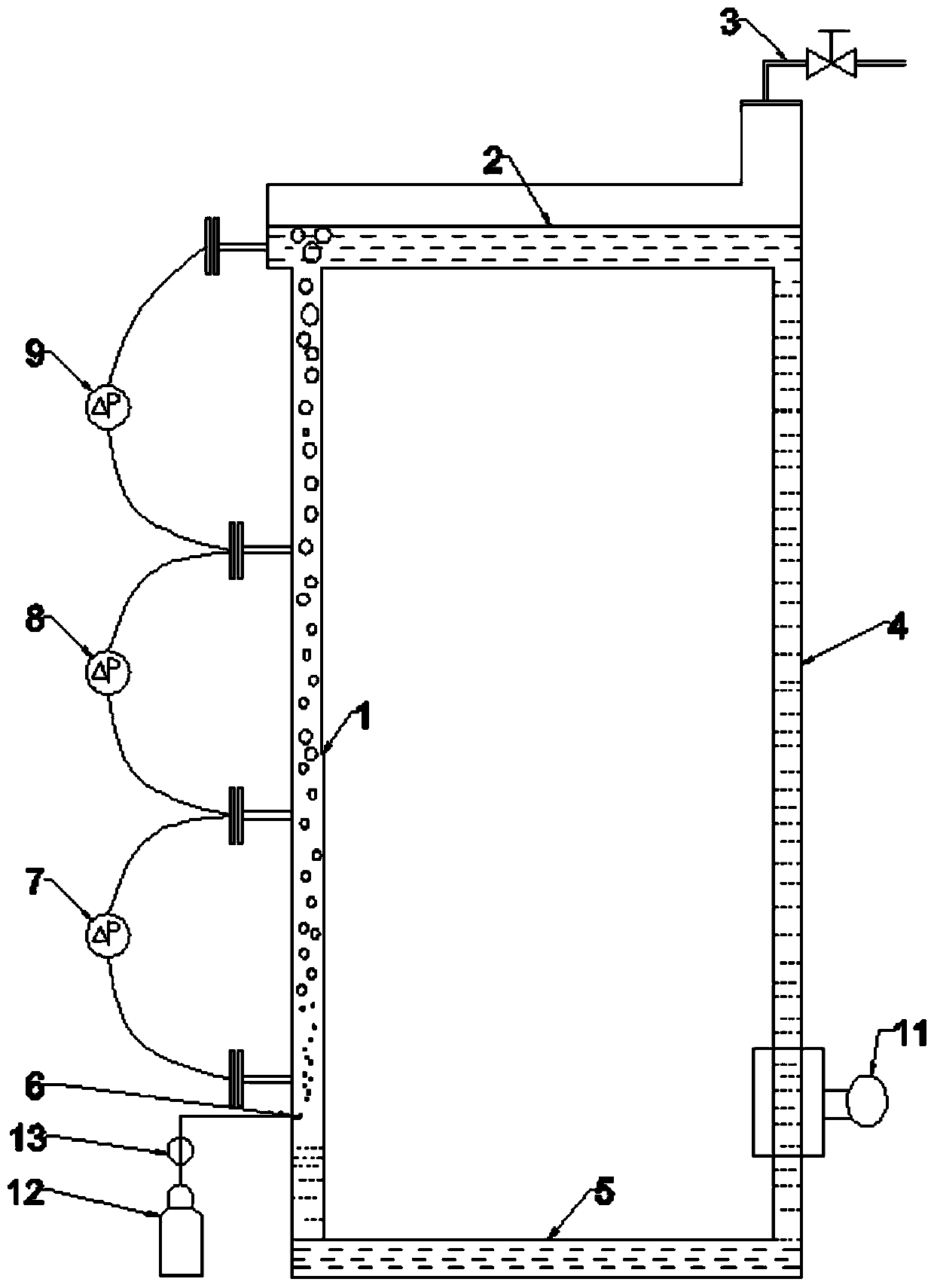

[0022] like figure 1 As shown, the liquid lead-bismuth alloy-inert gas two-phase flow cavitation fraction measuring device based on the differential pressure method of the present invention is used in the lead-bismuth alloy circuit, including a gas-liquid two-phase flow rising section 1 and a horizontal gas-liquid separation section 2 , the single-phase liquid descending section 4 and the single-phase liquid horizontal section 5 are sequentially connected to form a circuit; wherein the gas-liquid two-phase flow ascending section 1 is arranged with a gas injection port 6, a first differential pressure gauge 7, a second differential pressure gauge 8, The third differential pressure gauge 9 and the single-phase liquid descending section 4 are provided with an electromagnetic flowmeter 11 . The high-pressure gas storage tank 12 is connected to the gas injection port 6 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com