Folded-plate-shaped photovoltaic assembly, front glass used by folded-plate-shaped photovoltaic assembly and photovoltaic system

A photovoltaic module and front glass technology, applied in the field of photovoltaic systems, can solve the problems of photovoltaic module power generation restriction, limited number of solar cells, large energy loss, etc., and achieve the effect of reducing internal stress, high power generation, and increasing power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

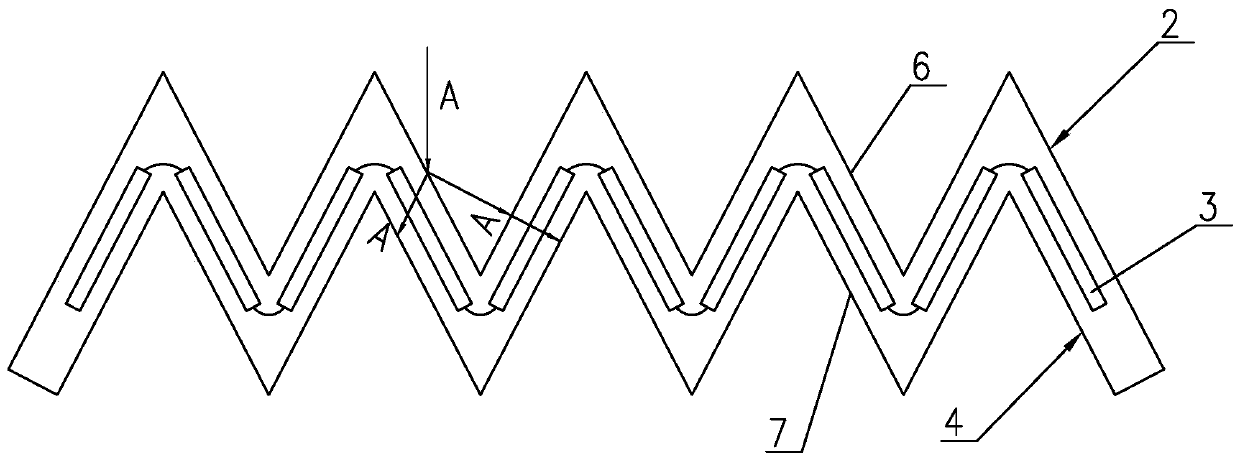

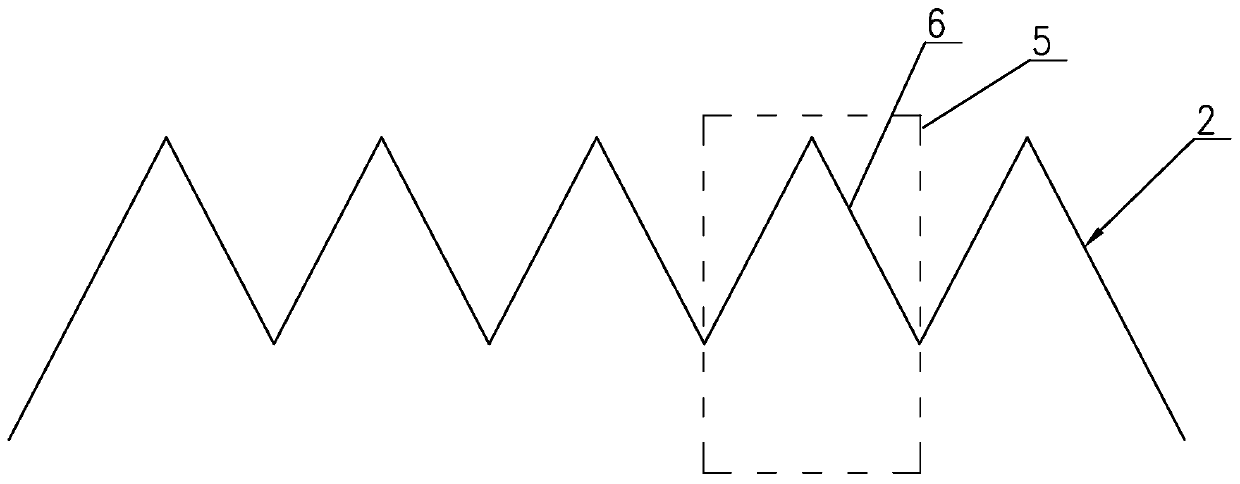

[0039] Such as figure 1 and 2 As shown, it is a folded-plate photovoltaic module of the present invention, which includes front glass 2, battery body and back surface layer arranged in sequence from top to bottom, front glass 2 and back surface layer are respectively mainly connected by multiple A folded plate structure composed of two V-shaped units, the front glass 2 and the V-shaped unit of the back surface layer correspond up and down, and a space for placing the battery body is formed between the two.

[0040] In this embodiment, the photovoltaic module is a crystalline silicon battery module, specifically a double-sided battery module, the overall shape is rectangular and flat, and it includes a front glass 2, a hot melt adhesive layer ( (omitted in the figure), a battery string formed by several solar cells 3 , a hot melt adhesive layer (omitted in the figure) and a back plate 4 . The solar battery sheet 3 is a double-sided battery, and the back plate 4 is a glass pla...

Embodiment 2

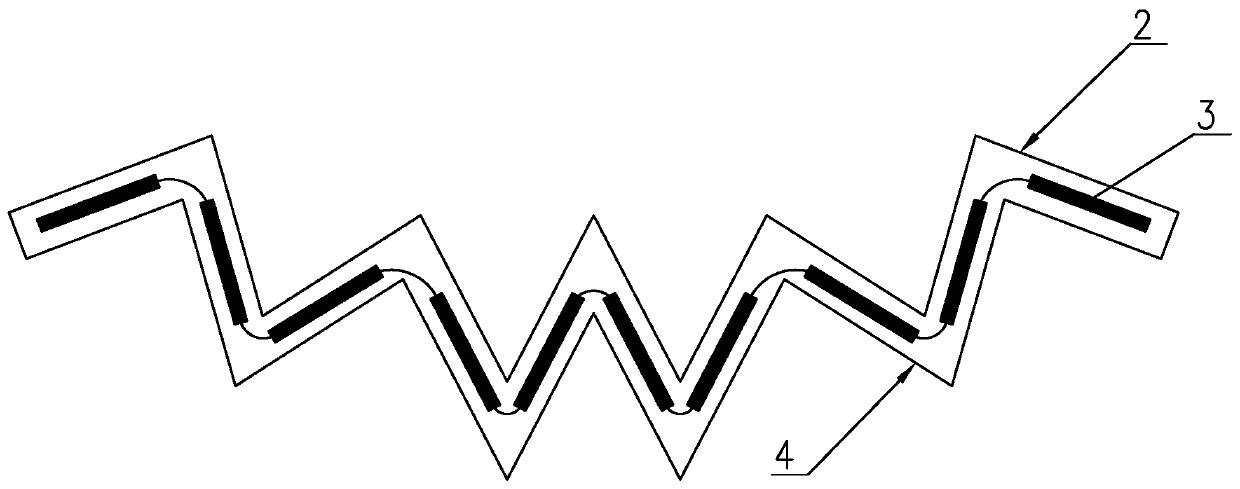

[0046] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the photovoltaic module of this embodiment is bent downwards in the transverse direction (in other embodiments, it can also be in the longitudinal direction) (in other embodiments, it can also be Bending upward) so that the front glass 2 and the back plate 4 become concave (in other embodiments, may also be convex) curved plates. The advantage of the photovoltaic module of this embodiment is that as the sun moves, there are solar cells facing the optimal irradiation direction at each angular position of the photovoltaic module, which can increase solar energy absorption.

[0047] In this embodiment, the photovoltaic module is curved, and the included angles of the two inclined panels of all the V-shaped units can be the same, or partly the same, and partly different, which can be determined according to the actual situation.

Embodiment 3

[0049] Such as Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 is that the photovoltaic module of this embodiment is a pot-shaped body whose bottom surface is a horizontal plane 9 and whose wall surface is a spherical curved surface 10, wherein there are a plurality of solar cells 3a located on the horizontal plane And successively connected to form a ring, and the solar cells 3b located on the curved surface of the spherical segment are in multiple groups and diverge ( Figure 4 Only two groups of solar cells are drawn in the figure), each group of solar cells 3b is connected in series (in other embodiments, it can also be connected in parallel) and is correspondingly connected with one of the solar cells 3a located in the horizontal plane, and each group is in the outer The solar cells 3c on the edge are connected successively to form a ring.

[0050] In the present embodiment, the front glass 2 and the back plate 4 are all pot-shaped, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com