A method of processing solid electrolyte and a method of testing element content in solid electrolyte

A technology of solid electrolyte and element content, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrical components, etc., can solve the problems of difficulty in dissolving LATP, component testing without LATP, and difficulty in conforming to actual conditions, and achieves the effect of a simple method.

Active Publication Date: 2021-03-05

BEIJING EASPRING MATERIAL TECH CO LTD +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, solid-state electrolytes are an emerging research field, and there are no relevant methods and literatures to test the components of LATP.

After LATP is sintered at high temperature, its structure is very stable. In addition, titanium and phosphorus element compounds are not easily soluble in common acids and alkalis. Therefore, it is very difficult to dissolve LATP. At present, there is no good dissolution method. Due to the lack of testing methods, LATP The amount of each element is generally only calculated by the amount of input, which is difficult to meet the actual situation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

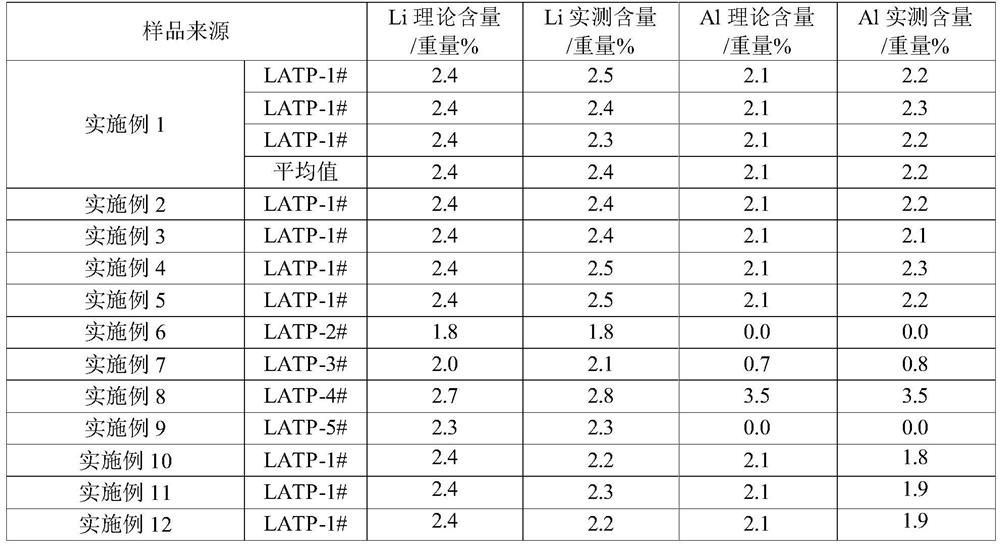

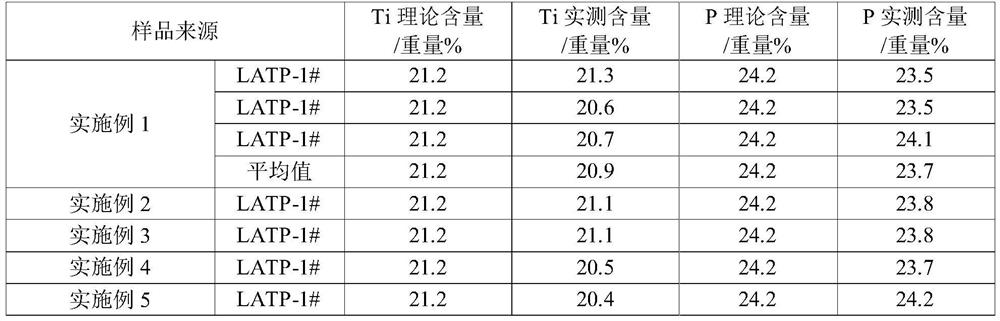

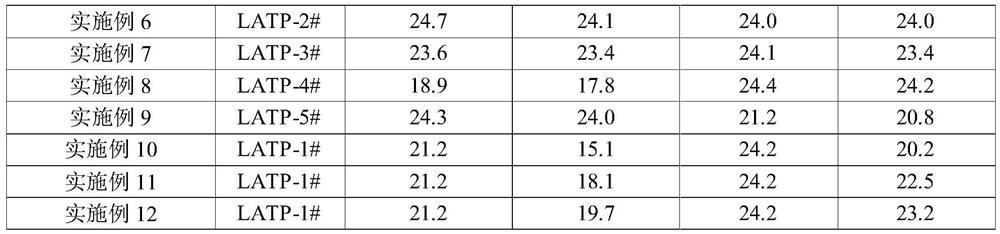

Embodiment 10

[0073] In embodiment 10: described acid is the hydrochloric acid that concentration is 12mol / L;

Embodiment 11

[0074] In embodiment 11: described acid is the sulfuric acid that concentration is 18.4mol / L;

Embodiment 12

[0075] In Example 12: the acid is a mixed acid of hydrochloric acid with a concentration of 12 mol / L and sulfuric acid with a concentration of 18.4 mol / L, wherein the mixing volume ratio of hydrochloric acid and sulfuric acid is 1:1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of batteries, and discloses a method for processing solid electrolytes and a method for testing element content in solid electrolytes. The method comprises: (1) first contacting a solid electrolyte with an alkaline substance to obtain a first contact material, the temperature of the first contact being 500-1000°C; (2) combining the first contact material with a solvent Carrying out the second contact to obtain the first contact material solution; (3) performing the third contact with the first contact material solution and acid to obtain the solid electrolyte solution. The method provided by the invention can test the content of lithium, aluminum, titanium, phosphorus and other elements in the solid electrolyte, the method is simple, and the test result has good reproducibility and high accuracy.

Description

technical field [0001] The invention relates to the technical field of batteries, in particular to a method for processing solid electrolytes and a method for testing element content in solid electrolytes. Background technique [0002] In recent years, the increasingly prominent energy crisis and environmental pollution have prompted the rapid development of new energy technologies. Lithium-ion batteries are widely used in portable power tools, electronic equipment, electric vehicles, and energy storage due to their outstanding advantages such as high voltage, high energy density, good cycle performance, small self-discharge, and no memory effect. However, with the promotion of lithium-ion batteries, their safety performance and cruising range have become the focus of widespread attention. How to improve the energy density of lithium-ion batteries while improving their safety performance and cycle performance has become a key issue that needs to be solved urgently. [0003]...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M10/0562H01M10/058G01N21/73G01N21/31

CPCG01N21/31G01N21/73H01M10/0562H01M10/058Y02E60/10Y02P70/50

Inventor 王玉娇王文波付海宽岳鹏刘亚飞陈彦彬关志波

Owner BEIJING EASPRING MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com