Artificial fiber fabric with fireproof function

A man-made fiber and fabric technology, applied in textiles and papermaking, coatings, layered products, etc., can solve problems such as fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

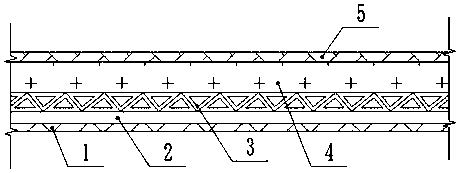

[0025] A man-made fiber fabric with fireproof function, such as figure 1 As shown, including the fiber fabric inner layer 2, the non-woven fabric layer 3, the fiber fabric outer layer 4, the fiber fabric outer layer 4 and the fiber fabric inner layer 2 are respectively arranged on the upper surface and the lower surface of the non-woven fabric layer 3; The bottom surface of the fiber fabric inner layer 2 is provided with a first fireproof coating 1 , and the top surface of the fiber fabric outer layer 4 is provided with a second fireproof coating 5 .

[0026] Wherein, the non-woven fabric layer 3 is made of the following components by weight: 70-90 parts by mass of polypropylene, 20-40 parts by mass of polypropylene fiber, 20-40 parts by mass of polyester fiber, 20-40 parts by mass of carbon fiber, 10-30 parts by mass of phenylenediamide phthalamide, 20-40 parts by mass of nylon chemical fiber, 8-10 parts by mass of polymethyl methacrylate, 10-20 parts by mass of viscose chemi...

Embodiment 2

[0031] A man-made fiber fabric with a fireproof function, comprising a fiber fabric inner layer 2, a non-woven fabric layer 3, and a fiber fabric outer layer 4, and the fiber fabric outer layer 4 and the fiber fabric inner layer 2 are respectively arranged on the non-woven fabric layer 3 The upper surface and the lower surface of the fiber fabric inner layer 2 are provided with a first fireproof coating 1, and the top surface of the fiber fabric outer layer 4 is provided with a second fireproof coating 5.

[0032] The non-woven fabric layer 3 is made of the following components in parts by weight: 75-85 parts by mass of polypropylene, 25-35 parts by mass of polypropylene fiber, 25-35 parts by mass of polyester fiber, 25-35 parts by mass of carbon fiber, benzene two 15-25 parts by mass of formamide, 25-35 parts by mass of nylon chemical fiber, 8-9 parts by mass of polymethyl methacrylate, 12-18 parts by mass of viscose chemical fiber, 8-9 parts by mass of polycarbonate, 12-18 p...

Embodiment 3

[0034] A man-made fiber fabric with a fireproof function, comprising a fiber fabric inner layer 2, a non-woven fabric layer 3, and a fiber fabric outer layer 4, and the fiber fabric outer layer 4 and the fiber fabric inner layer 2 are respectively arranged on the non-woven fabric layer 3 The upper surface and the lower surface of the fiber fabric inner layer 2 are provided with a first fireproof coating 1, and the top surface of the fiber fabric outer layer 4 is provided with a second fireproof coating 5.

[0035]The non-woven fabric layer 3 is made of the following components in parts by weight: 80 parts by mass of polypropylene, 30 parts by mass of polypropylene fiber, 30 parts by mass of polyester fiber, 30 parts by mass of carbon fiber, and 20 parts by mass of phenylenediamide phthalamide , 30 parts by mass of nylon chemical fiber, 9 parts by mass of polymethyl methacrylate, 15 parts by mass of viscose chemical fiber, 8 parts by mass of polycarbonate, 15 parts by mass of am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com