A kind of anti-blue light high-strength aluminosilicate glass and preparation method thereof

An aluminosilicate glass, high-strength technology, used in glass manufacturing equipment, glass furnace equipment, glass production and other directions, can solve problems such as eye diseases, and achieve a simple preparation process, eye protection, and high visible light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

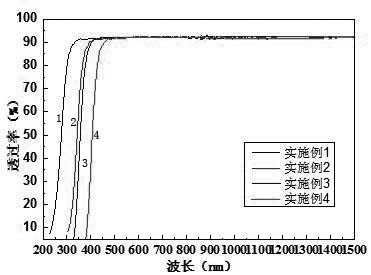

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with specific embodiment:

[0025] An anti-blue light high-strength aluminosilicate glass and a preparation method thereof, the specific implementation steps are as follows:

[0026] (1) Weighing: Weigh the corresponding compound according to the proportioning of Examples 1 to 4 in Table 1;

[0027] (2) Pre-calcination: Mix the weighed cadmium sulfide, cadmium selenide and zinc oxide evenly, and place them in an electric furnace at 400°C for 1 hour, and cool with the furnace;

[0028] (3) Mixing: mix the mixture of cadmium sulfide, cadmium selenide and zinc oxide obtained in step (2) with other compounds, and grind and mix uniformly to obtain a batch;

[0029] (4) Firing: After heating the electric furnace to 1000°C, load the ingredients in a crucible with a corundum cover and preheat it at the furnace door for 3 minutes, then put it into the furnace and raise the temperature to 1600°C, and keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com