High-strength and high-heat-conductive Si3N4 ceramic material and preparation method thereof

A technology of ceramic materials and raw materials, applied in the field of Si3N4 ceramic materials and its preparation, can solve the problems of reducing thermal conductivity, reducing phonon mean free path, and low thermal conductivity second equivalence, so as to improve thermal conductivity and facilitate liquid phase Effect of mass transfer and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh LaB 6 Powder 4.44g, with 94.41g Si 3 N 4 Mix the powder with 1.16g MgO powder, add 66.7g alcohol as solvent, 100g Si 3 N 4 The ball is the ball milling medium, milled at 300rpm for 12h, then baked in an 80°C constant temperature oven for 18h, ground, and passed through a 100-mesh sieve; the obtained powder was dry-pressed and preformed under a pressure of 30MPa and then loaded into a graphite hot-pressing mold. Place the sample in a carbon tube furnace and fill it with N 2 As a protective gas, sintering at 1550°C and 60MPa pressure for 60 minutes, the thermal conductivity is 24.8w / (m·K), the bending strength is 649.4±24.2MPa, and the fracture toughness is 6.96±0.21MPa·m 1 / 2 , Si with a Vickers hardness of 19.35±0.18GPa 3 N 4 ceramics.

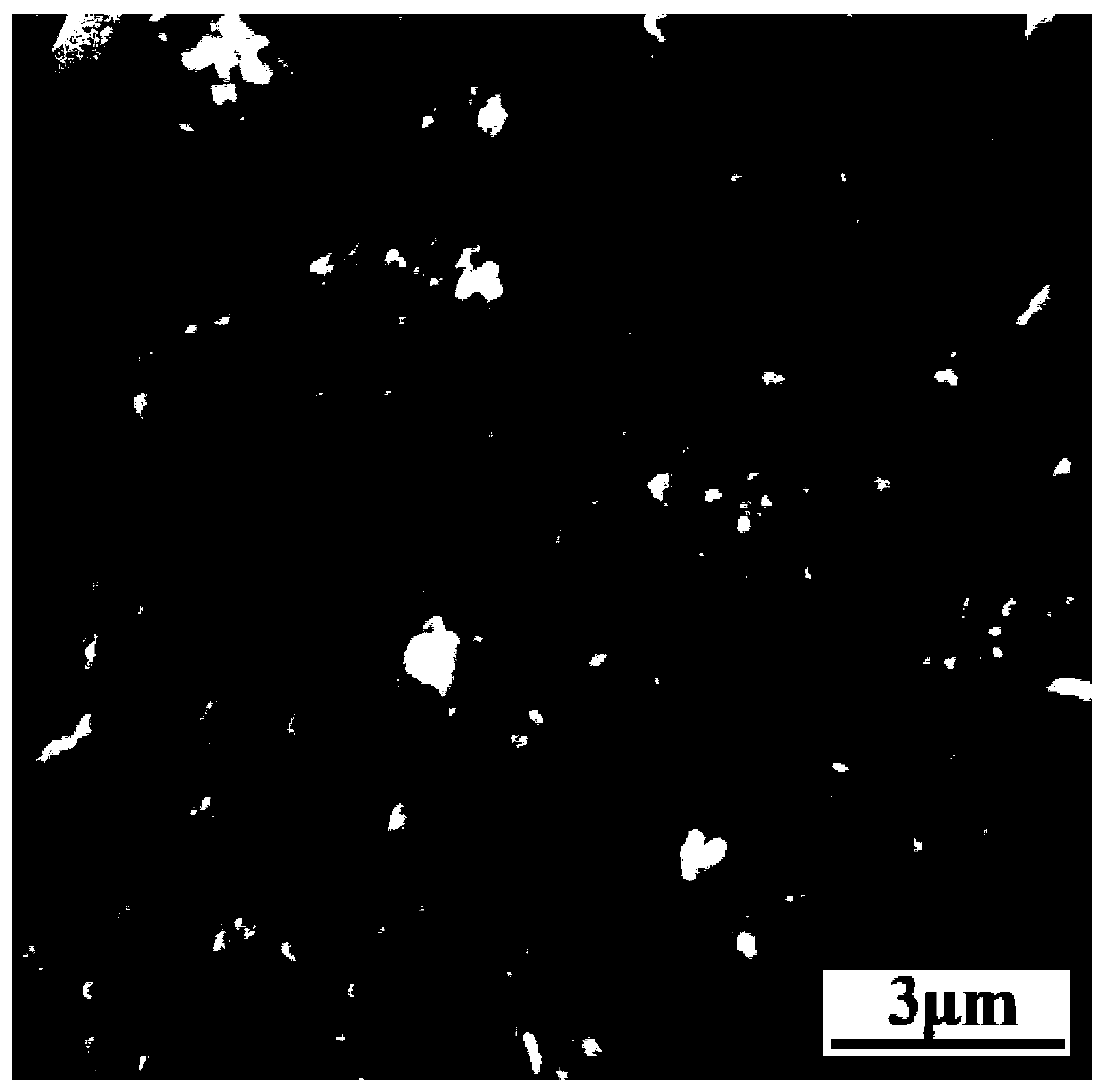

[0037] For the Si obtained in Example 1 3 N 4 Ceramic cross-section observation, the results are as follows figure 1 As shown, due to the lower sintering temperature, Si 3 N 4 The phase transition does not occur obvious...

Embodiment 2

[0039] Weigh LaB 6 Powder 4.44g, with 94.41g Si 3 N 4 Mix the powder with 1.16g MgO powder, add 66.7g alcohol as solvent, 100g Si 3 N 4 The ball is the ball milling medium, milled at 300rpm for 12h, then baked in an 80°C constant temperature oven for 18h, ground, and passed through a 100-mesh sieve; the obtained powder was dry-pressed and preformed under a pressure of 30MPa and then loaded into a graphite hot-pressing mold. Place the sample in a carbon tube furnace and fill it with N 2 As protective gas, sinter at 1550°C, 60MPa pressure for 60 minutes, then at 1900°C, 2MPa N 2 Treated under air pressure for 1h, the thermal conductivity is 69.8w / (m·K), the bending strength is 893.3±36.3MPa, and the fracture toughness is 8.43±0.27MPa·m 1 / 2 , Si with a Vickers hardness of 14.94±0.12GPa 3 N 4 ceramics.

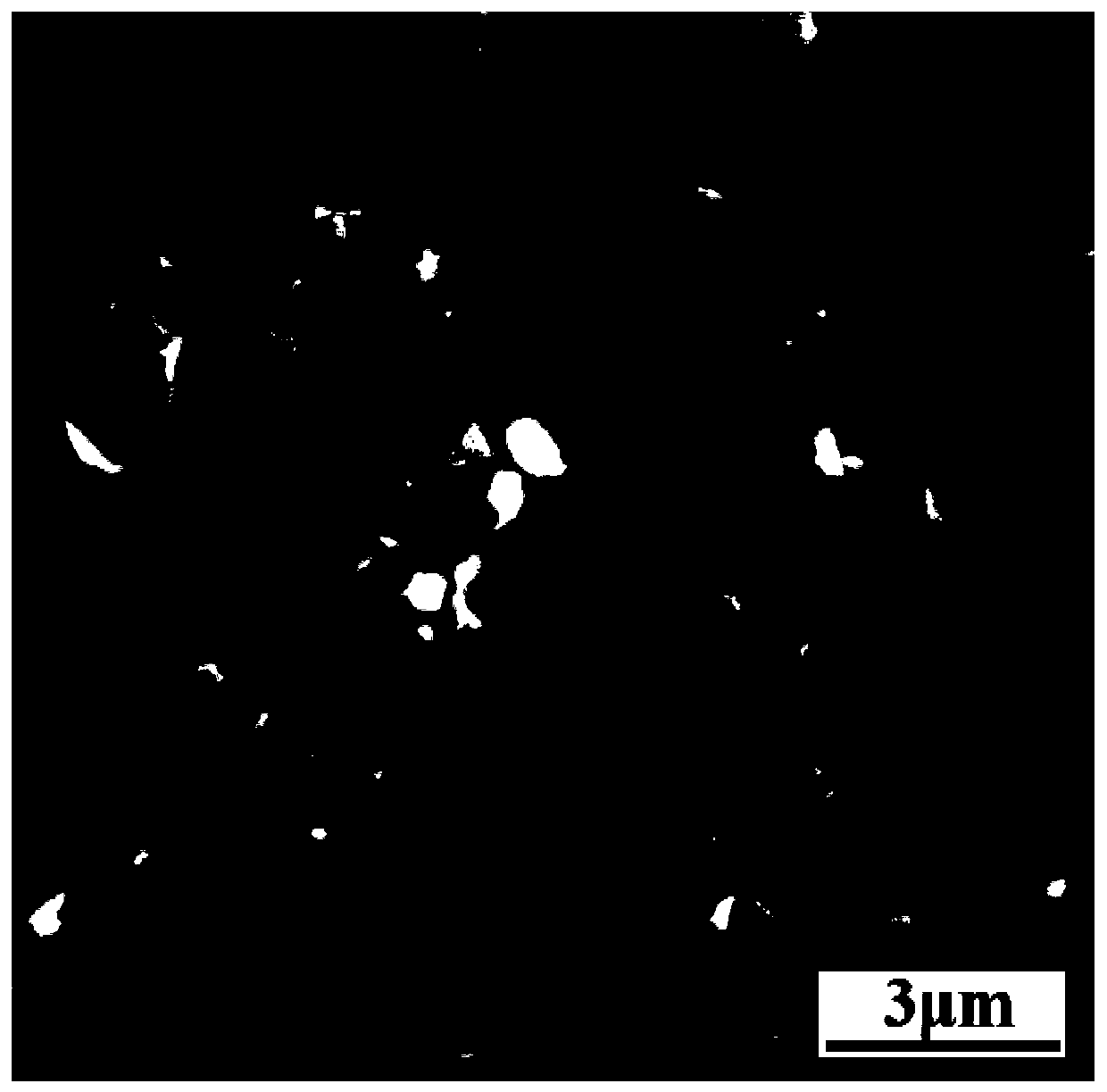

[0040] For the Si obtained in Example 2 3 N 4 Ceramic cross-section observation, the results are as follows figure 2 As shown, Si 3 N 4 The grains in ceramics have c...

Embodiment 3

[0042] Weigh LaB 6 Powder 4.44g, with 94.41g Si 3 N 4 Mix the powder with 1.16g MgO powder, add 100g alcohol as solvent, 200g Si 3 N 4 The ball is the ball milling medium, milled at 200rpm for 16h, then baked in a 90°C constant temperature oven for 16h, ground, and passed through a 200-mesh sieve; the obtained powder was dry-pressed and preformed under a pressure of 50MPa and then loaded into a graphite hot-pressing mold. Place the sample in a carbon tube furnace and fill it with N 2 As a protective gas, sintering at 1650°C and 60MPa pressure for 120 minutes, the thermal conductivity is 48.3w / (m·K), the bending strength is 986.5±43.9MPa, and the fracture toughness is 7.43±0.19MPa·m 1 / 2 , Si with a Vickers hardness of 16.21±0.15GPa 3 N 4 ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com