Production process method for isooctyl acrylate

A technology for the production of isooctyl acrylate, which is applied in the separation/purification of carboxylic acid esters, preparation of carboxylic acid esters, chemical instruments and methods, etc., and can solve the problem of disproportionate consumption of raw materials, multiple raw materials, and purity of isooctyl acrylate Insufficient and other problems, to achieve the effect of good purity, high preparation yield, scientific and reasonable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

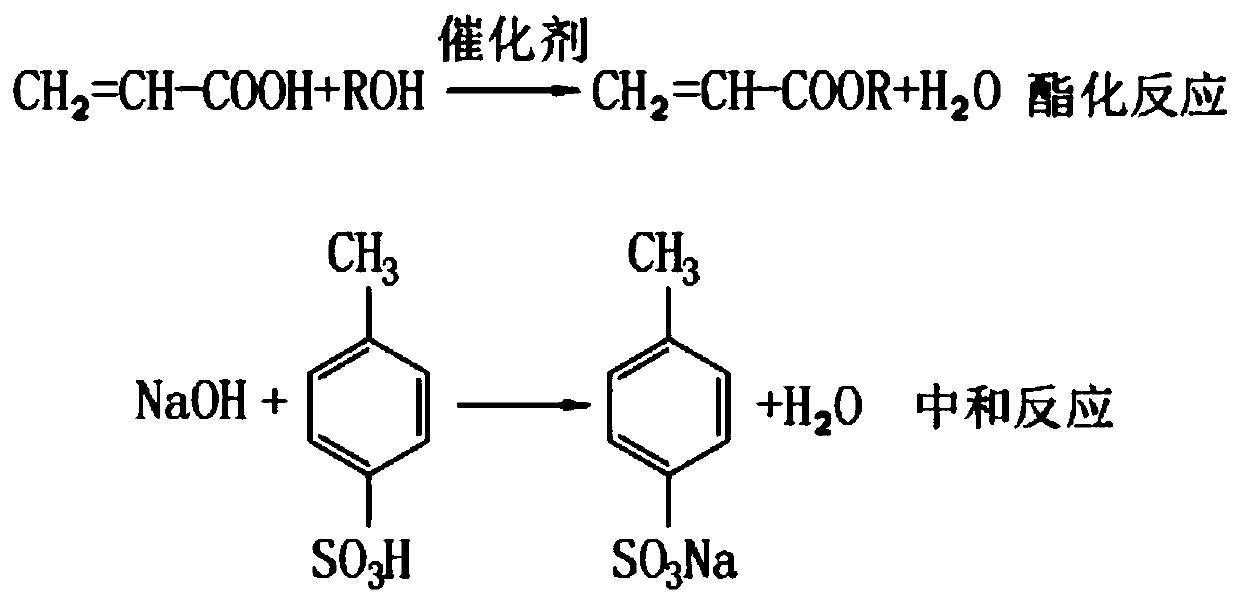

[0047] see figure 1 , a production process of isooctyl acrylate, comprising the following steps:

[0048] S1, esterification:

[0049] (a) 8200L of acrylic acid is transported into the esterification reactor by a pump;

[0050] (b) iso-octanol is delivered to the esterification reactor and the esterification reflux spray tank respectively by the pump, and the amount of iso-octanol is 7000L respectively;

[0051] (c) 400L of esterification inhibitor liquid is delivered to the reactor by a pump;

[0052] (d) drop the p-toluenesulfonic acid of 750Kg in the catalyst tank, add the water of 6000Kg to dissolve, and sample the content of the aqueous solution;

[0053] (e) calculate corresponding esterification charging amount according to content, the aqueous solution amount that drops into guarantees to contain 90Kg pure p-toluenesulfonic acid;

[0054] (f) The reclaimed alcohol 5000L in the delightening tower reclaims the alcohol tank is transported in the esterification reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com