Composite damping material and preparation method thereof

A composite damping material and polymer technology, applied in the field of vibration damping materials, can solve problems such as poor damping effect in high temperature areas, complicated damping material preparation process, and restrictions on high temperature applications, to achieve good damping effect, excellent damping effect, and vibration reduction The effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention also provides a method for preparing the composite damping material described in the above technical solution, comprising the following steps:

[0073] a) Under the action of the initiator, the acrylate monomer, the vinyl heterocyclic compound and the chain transfer agent are polymerized to obtain a polymer matrix;

[0074] b) mixing the polymer matrix with nano-heteropolyacid particles to obtain a composite damping material;

[0075] The acrylate monomer is one or more of acrylate and methacrylate;

[0076] The ester group in the acrylate monomer is a C1-C8 ester group;

[0077] The vinyl heterocyclic compound is selected from one or more of vinylimidazole, 2-vinylpyridine and 4-vinylpyridine;

[0078] The chain transfer agent is 1-(O-ethylsulfonate)ethylbenzene.

[0079] According to the invention, under the action of the initiator, the acrylic acid ester monomer, the vinyl heterocyclic compound and the chain transfer agent are polymerized to ...

Embodiment 1

[0110] 1.1 Preparation of materials

[0111] S1. Pass vinylimidazole and butyl acrylate through a neutral alumina column to remove the polymerization inhibitor. Mix according to the mol ratio of butyl acrylate: vinylimidazole=9: 1, meanwhile, add chain transfer agent and initiator according to the mol ratio of butyl acrylate monomer: chain transfer agent: initiator=100: 1: 0.2; Then add anhydrous dioxane solvent (butyl acrylate monomer: solvent = 10g: 6mL), freeze and pump three times, then react at 70°C for 12h under nitrogen, and dissolve the resulting reaction solution in a mixture of methanol and water. (The volume ratio of methanol:water is 85:15) precipitated out, and dried under vacuum at 80° C. to obtain the polymer represented by formula (1).

[0112] The reaction scheme of above-mentioned reaction is as follows:

[0113]

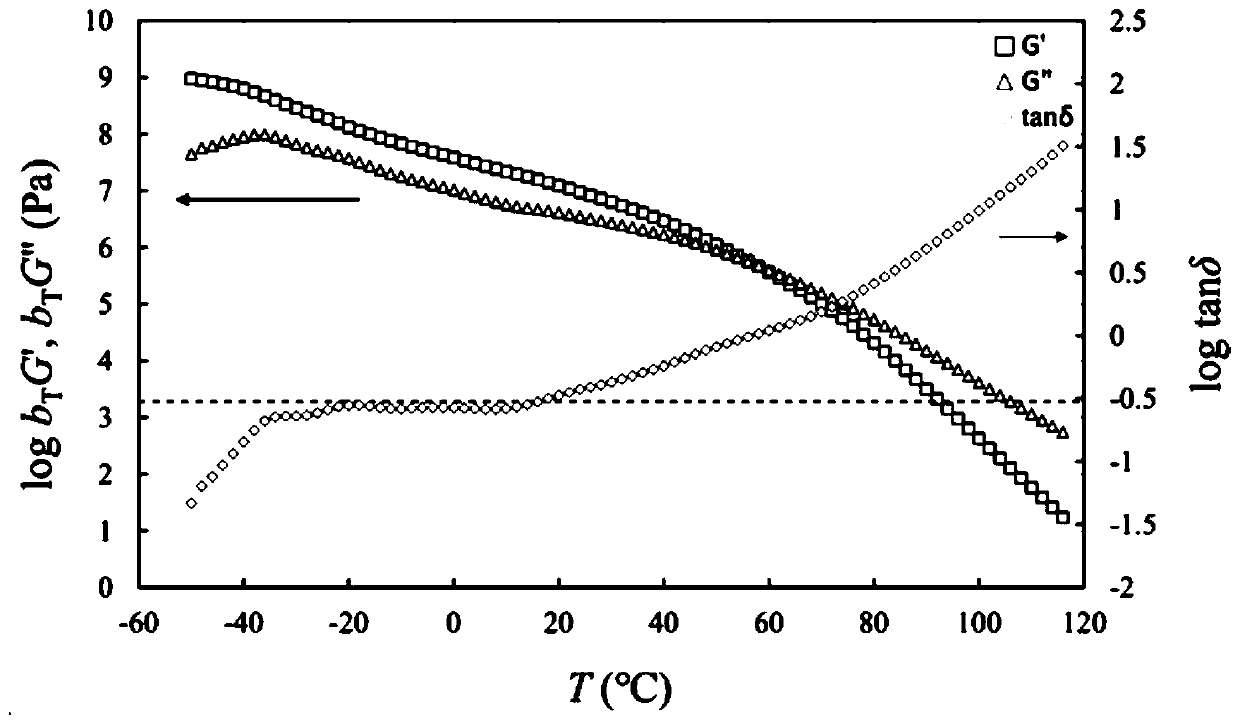

[0114] The molecular weight of the obtained polymer and the molar ratio of butyl acrylate fragments to vinylimidazole fragments in the polyme...

Embodiment 2

[0123] 1.1 Preparation of materials

[0124] S1. Pass 2-vinylpyridine and hexyl methacrylate through a neutral alumina column to remove the polymerization inhibitor. Mix according to the molar ratio of hexyl methacrylate:2-vinylpyridine=9:1, meanwhile, add the chain according to the molar ratio of hexyl methacrylate monomer:chain transfer agent:initiator=100:1:0.2 transfer agent and initiator; then add anhydrous dioxane solvent (hexyl methacrylate monomer: solvent = 10g: 6mL), freeze and pump three times, then react at 70°C for 12h under nitrogen, and the resulting reaction solution Precipitate in methanol and dry under vacuum at 80°C to obtain the polymer represented by formula (1).

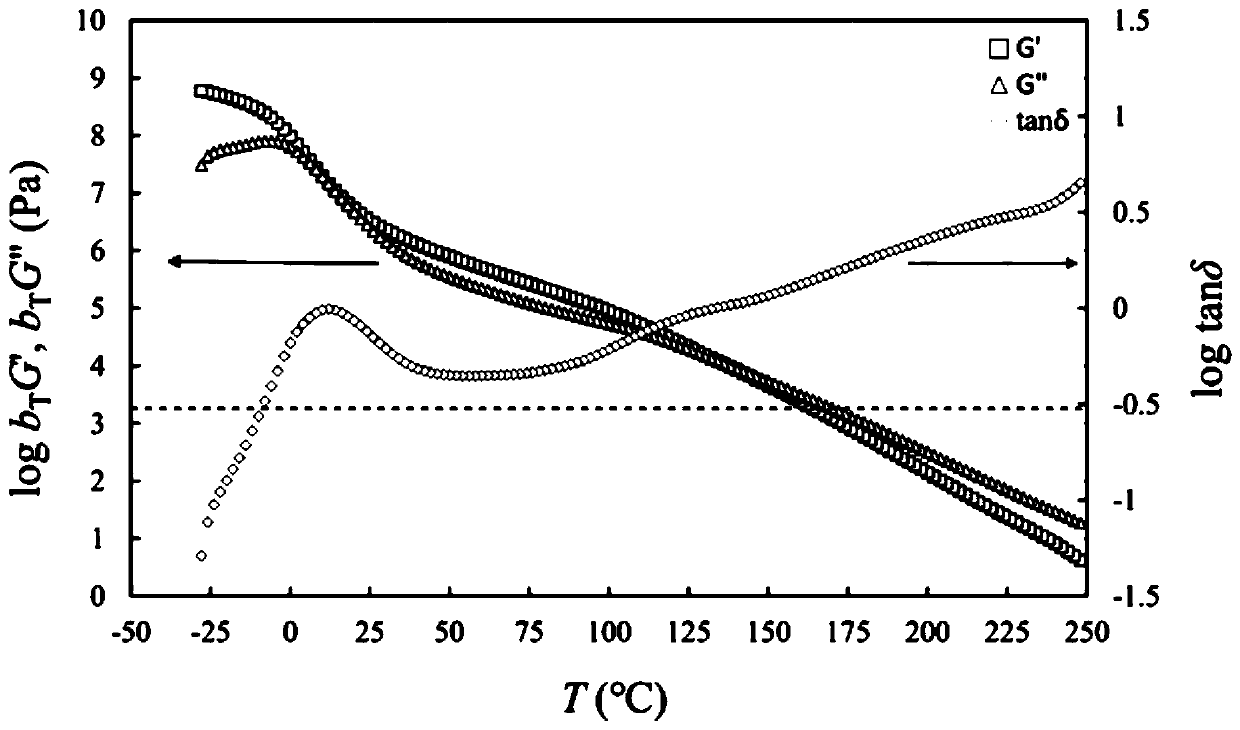

[0125] The molecular weight of the obtained polymer and the molar ratio of butyl acrylate fragments to vinylimidazole fragments in the polymer chain were tested by GPC and NMR respectively. The results showed that the number average molecular weight was 162300 g / mol, m was 914.2, and n was 61.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com