Macromolecular reflective functional material for automobile, and preparation method and production equipment thereof

A technology for functional materials and production equipment, applied in the field of automotive functional materials, can solve the problems of many equipment and complicated preparation process, and achieve the effects of solving the complicated preparation process, improving oxidation resistance and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

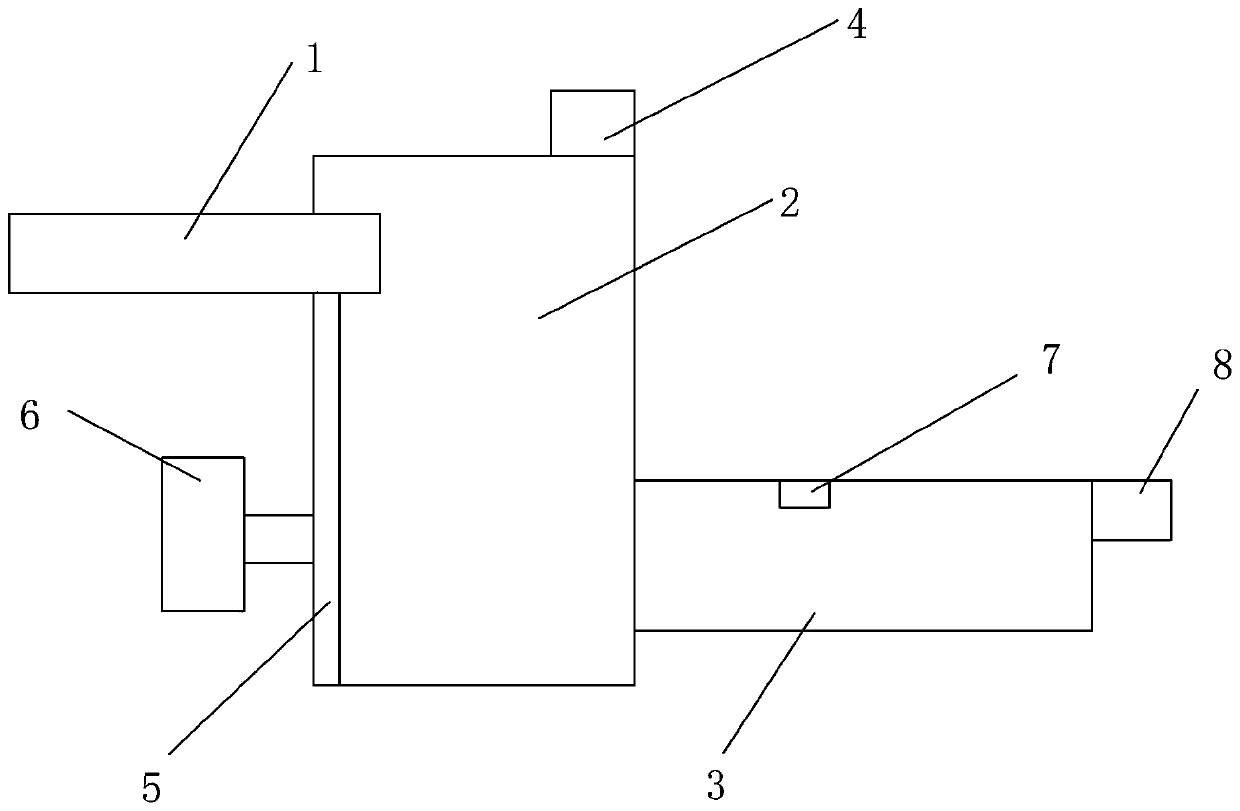

Image

Examples

Embodiment 1

[0032] The polymer reflective functional material for automobiles provided in this example is prepared from the following components in parts by weight: 35-45 parts of resin, 10-15 parts of nickel-plated glass microspheres, 3 parts of titanium-loaded zinc hydroxyapatite -4 parts, 5-10 parts of nano titanium dioxide, 5-8 parts of diopside, 2-4 parts of polymerized tung oil, 5-10 parts of persimmon tannin, 12-15 parts of ultraviolet absorber, 3-8 parts of flame retardant, 4-6 parts of antioxidant, 1-3 parts of stabilizer, 4-7 parts of curing agent, 5-8 parts of toner, 3-5 parts of rare earth polymer fluorescent material; the resin is a combination of polyamide resin and acrylic resin 3-10 parts of freshener, 2-3.5 parts of antifreeze of alcohol antifreeze, 5-8 parts of moisture-proof agent. The rare earth polymer fluorescent material is an acrylic rare earth polymer fluorescent material.

[0033] In the present invention, by adding reflective materials, rare earth polymer fluor...

Embodiment 2

[0049] The polymer reflective functional material for automobiles, preparation method and production equipment provided in this embodiment are basically the same as in Embodiment 1, except that:

[0050] The polymer reflective functional material for automobiles is prepared from the following components in parts by weight: 35 parts of resin, 10 parts of nickel-plated glass microspheres, 3 parts of titanium-loaded zinc hydroxyapatite, and 5 parts of nano-titanium dioxide , 5 parts of diopside, 2 parts of polymerized tung oil, 5 parts of persimmon tannin, 12 parts of ultraviolet absorber, 3 parts of flame retardant, 4 parts of antioxidant, 1 part of stabilizer, 4 parts of curing agent, 5 parts of toner, 3 parts of rare earth polymer fluorescent material; the resin is a 1:1 combination of polyamide resin and acrylic resin; 3 parts of freshener, 2 parts of alcohol antifreeze agent, and 5 parts of moisture-proof agent.

Embodiment 3

[0052]The polymer reflective functional material for automobiles, preparation method and production equipment provided in this embodiment are basically the same as in Embodiment 1, except that:

[0053] The polymer reflective functional material for automobiles is prepared from the following components in parts by weight: 40 parts of resin, 12.5 parts of nickel-plated glass microspheres, 3.5 parts of titanium-loaded zinc hydroxyapatite, and 8 parts of nano-titanium dioxide , 6 parts of diopside, 3 parts of polymerized tung oil, 6 parts of persimmon tannin, 14 parts of ultraviolet absorber, 5 parts of flame retardant, 5 parts of antioxidant, 2 parts of stabilizer, 5 parts of curing agent, 6 parts of toner, 4 parts of rare earth polymer fluorescent material; the resin is a 1:0.5 combination of polyamide resin and acrylic resin; 5 parts of freshener, 3 parts of alcohol antifreeze agent, and 6 parts of moisture-proof agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com