Polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation pipefitting and spraying method

A polyurethane, outer protective pipe technology, applied in the direction of pipes/pipe joints/pipes, thermal insulation, and protection of pipelines through thermal insulation, etc. Outstanding strength and toughness, avoiding economic losses, good structural flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

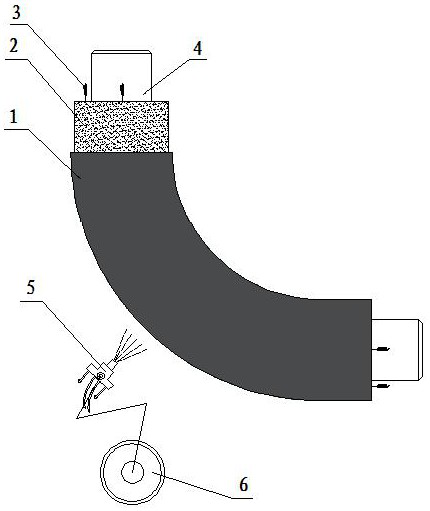

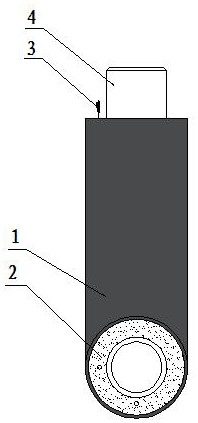

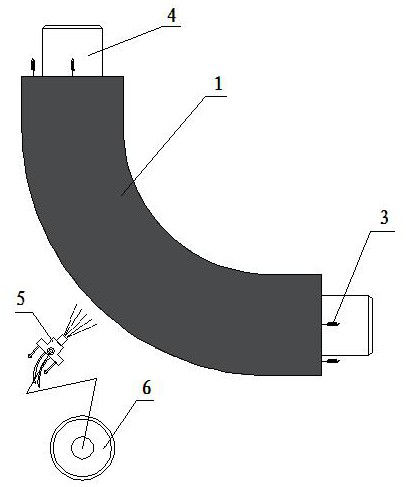

[0036] A prefabricated thermal insulation pipe fitting integrally formed by spraying polyurethane spraying outer protective pipe, which comprises: a prefabricated direct buried thermal insulation pipe fitting, the prefabricated direct buried thermal insulation pipe fitting includes a working pipe 4, and the outer surface of the working pipe is sprayed with polyurethane for protection by spraying equipment 5 Layer 2, and there is a welded joint of pipe fittings that does not spray the polyurethane protective layer at both ends of the working pipe. The outer surface of the polyurethane protective layer is sprayed with the polymer liquid outer protective layer 1 by the spraying equipment, and the described A group of alarm wires 3 are installed inside the polyurethane protective layer, and the polymer liquid outer sheath adopts a polymer liquid elastic material with a density of 1.2g / cm3, and its coating thickness is 1-20mm.

Embodiment 2

[0038] According to the polyurethane spray coating outer protection pipe described in Example 1, the integrally formed prefabricated thermal insulation pipe fittings are sprayed, and the spraying equipment is a polyurethane mixing nozzle and a high-pressure liquid spray gun, and the distance between the welding interface of the pipe fittings and the working pipe port is 10- 20mm, the polyurethane mixing nozzle and the high-pressure liquid spray gun are connected with the control device 6.

Embodiment 3

[0040] A spraying method for polyurethane spraying outer protective pipe spraying integrally formed prefabricated thermal insulation pipe fittings, the method includes the following steps: firstly, the pipe fittings adopt conventional heating pipe fittings, the model is DN15-DN4000, and the surface of the outer body is shot blasted to reach Sa2. 5 Industrial coating cleaning grade, polyurethane uses isocyanate, polyol and catalyst combined foaming agent;

[0041] Using fully automatic spraying polyurethane foaming technology equipment or hand-held mobile polyurethane foaming equipment, 360-degree polyurethane spraying and foaming insulation is applied to the pipe fittings, so that the performance parameters and technical indicators of the polyurethane insulation layer on the outer body of the pipe fittings meet the design requirements. Standard, the thermal conductivity is 0.026-0.032W / m·k;

[0042] A metal alarm line is pre-buried in the polyurethane insulation layer of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com