Efficient environment-friendly mixing vehicle

A kind of mixed vehicle, environmental protection technology, applied in the direction of mixer, mixing method, mixer accessories, etc., can solve the problems of difficult to dissolve quickly, difficult to dissolve, single function, etc., to improve the dissolution speed, reduce the occurrence probability of powder agglomeration, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments.

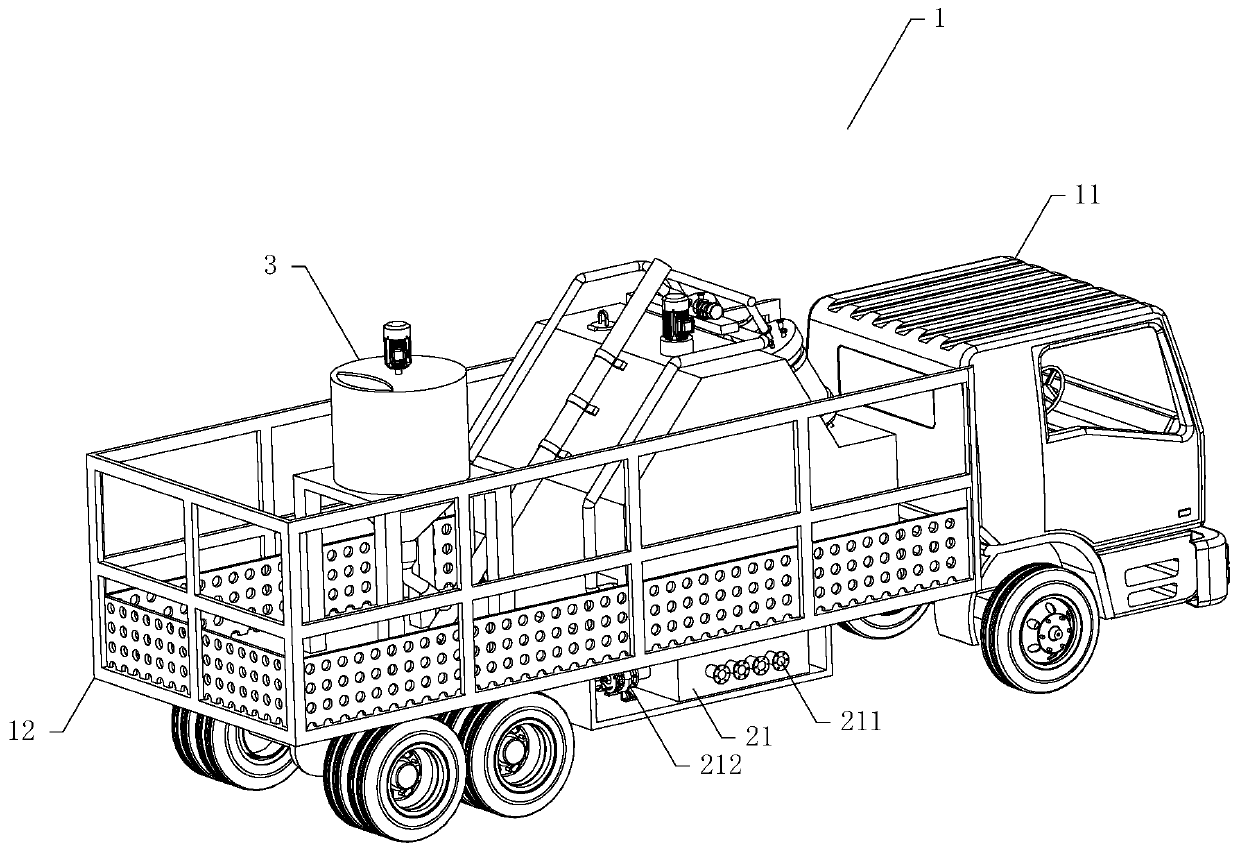

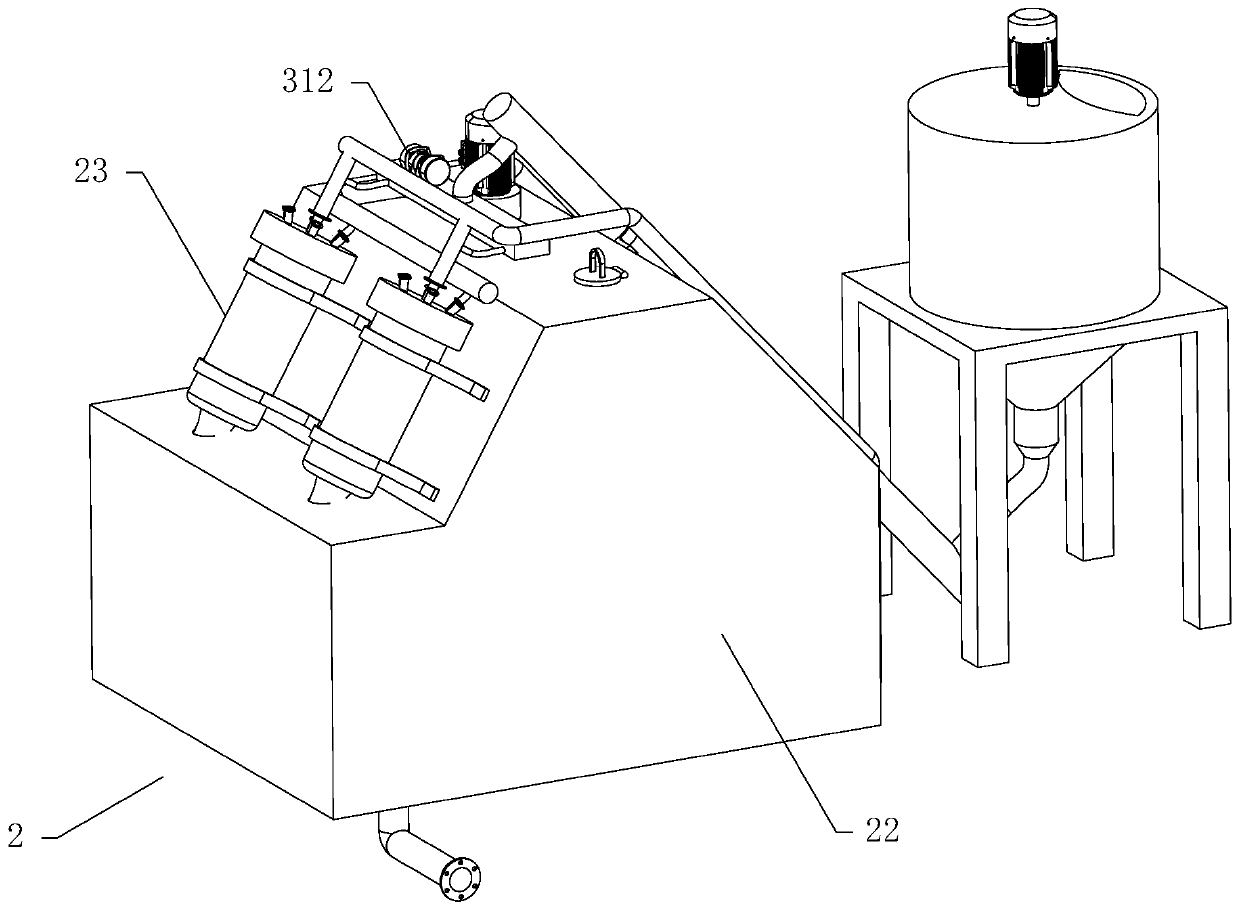

[0024] In this example, if figure 1 As shown, the vehicle is divided into a car body 1, a mixing chamber 2, and a silo 3. The car body 1 includes a head 11 for a driver, and a carrier 12 is arranged behind the head 11, and the carrier 12 is used to carry other equipment. . The carrier 12 is provided with a mixing chamber 2 , and the mixing chamber 2 is divided into a water tank 21 arranged at the bottom of the carrier 12 , a storage bin 22 arranged on the carrier 12 and a mixing drum 23 arranged on the storage bin 22 .

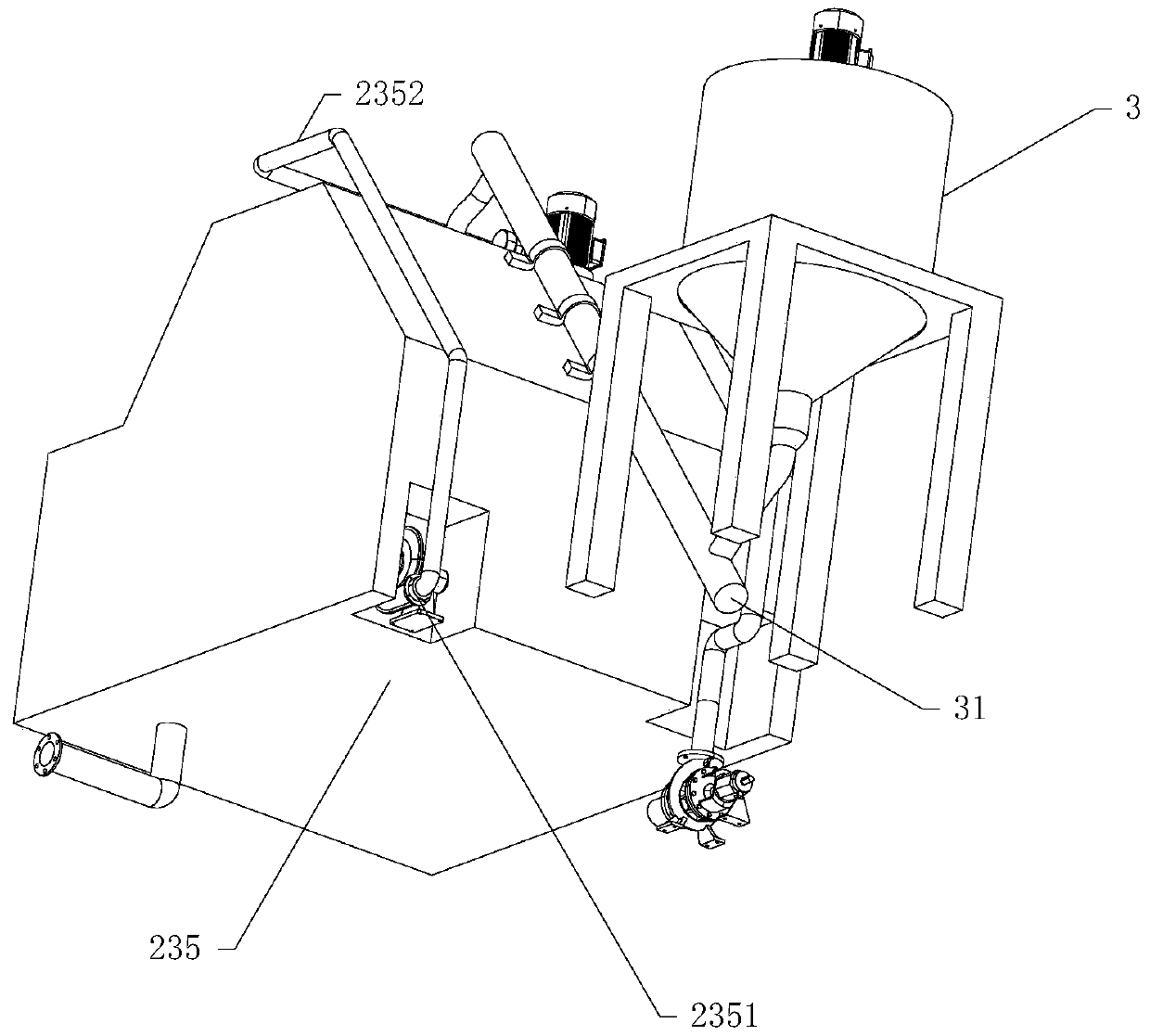

[0025] In this example, if figure 2 , Figure 5 As shown, the mixing drum 23 includes a rotating mixing drum 231 and a mixing chamber 232 disposed in the rotating mixing drum 231 . A powder nozzle 233 and a water nozzle 234 are arranged on the top of the rotating mixing drum 231 . In this example, if image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com