An all-solid-state electrolyte, preparation method thereof, and lithium ion battery

An electrolyte, all-solid-state technology, applied in the field of lithium-ion batteries, can solve the problems of reduced charge-discharge capacity and poor cycle performance of all-solid-state batteries, improve interface compatibility and interface stability, excellent adhesion, reduce Effect of risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention also provides a method for preparing any of the above-mentioned all-solid electrolytes, comprising the following steps:

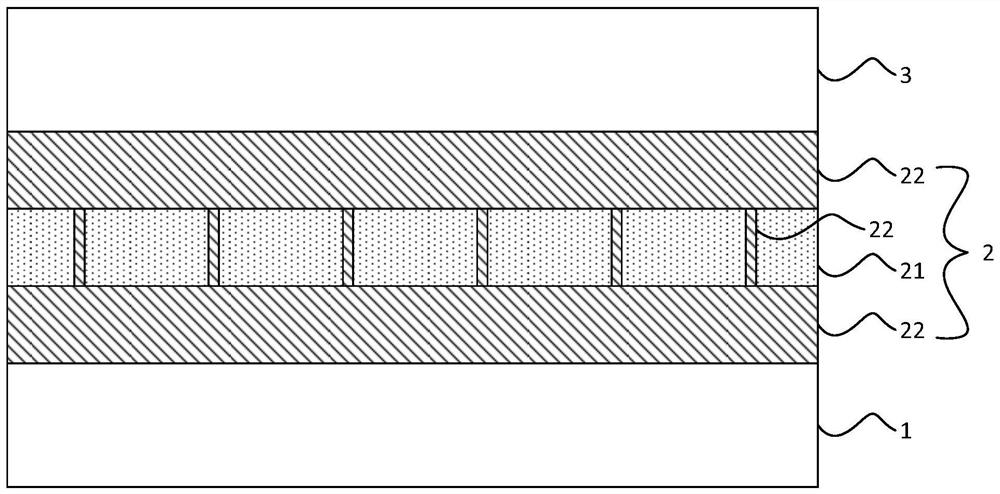

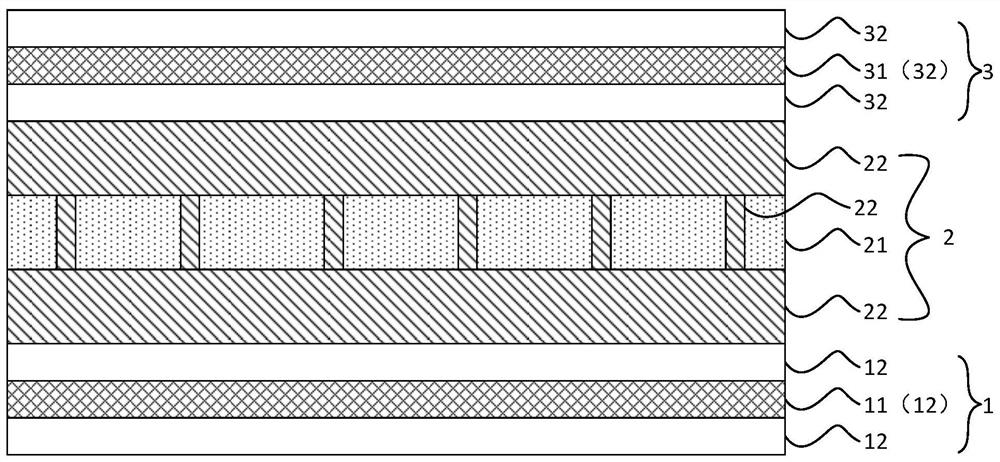

[0072] 1) compressing and drying the first slurry containing the inorganic electrolyte, polymer, and lithium salt to obtain a composite electrolyte functional layer;

[0073] 2) soaking the composite electrolyte functional layer in a surface modifier solution to obtain an intermediate functional layer;

[0074] 3) The first functional layer is provided on the lower surface of the intermediate functional layer, and the second functional layer is provided on the upper surface of the intermediate functional layer.

[0075] In step 1), the first slurry for obtaining the composite electrolyte functional layer is firstly prepared.

[0076] Specifically, the polymer and the lithium salt can be added into the solvent and stirred evenly to obtain an intermediate slurry, and then the inorganic electrolyte can be added to the intermediate...

Embodiment 1

[0105] The all-solid electrolyte of this example was prepared according to the following method:

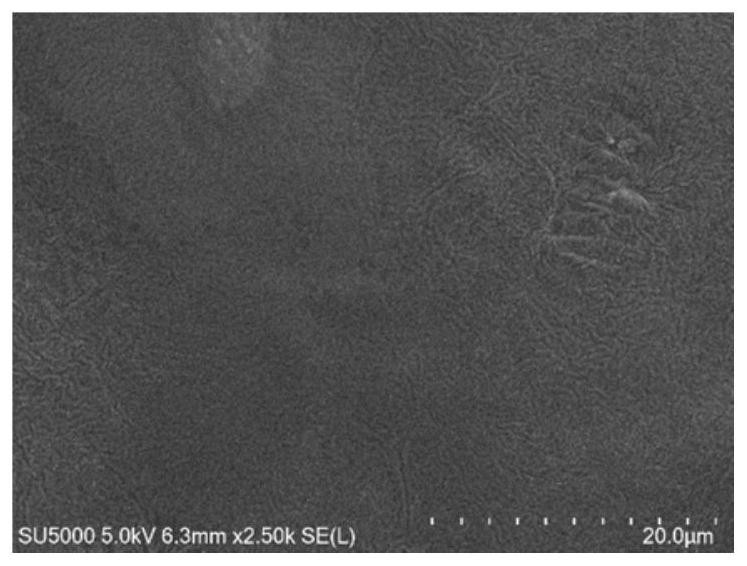

[0106] 1. PEO, lithium perchlorate (LiClO 4 ) and BMI-TFSI ionic liquid are dissolved in ACN according to the mass ratio of 8:6:1, and stirred evenly at 20°C for 3 hours to form a solution with a solid content of 3%; then add 95% mass based composite electrolyte functional layer to the above solution Proportion of Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 Inorganic electrolyte powder, stirred evenly, pressed to make the thickness 180 μm, vacuum dried at 100°C for 12 hours, to obtain a composite electrolyte functional layer;

[0107] Soak the above-mentioned composite electrolyte functional layer in methanol dopamine solution for 1 h, and then use a vacuum oven to dry in O 2 Dry at 60°C for 10 hours under the same conditions to obtain the intermediate functional layer;

[0108] 2. PEO, LiClO 4 Dissolve in ACN at a mass ratio of 8:3, stir for 12 hours to form a uniform second slurry, ...

Embodiment 2

[0113] The all-solid electrolyte of this example is prepared according to the following method:

[0114] 1. Combine PVDF-HFP, lithium perchlorate (LiClO 4 ) and BMI-TFSI ionic liquid were dissolved in DMF according to the mass ratio of 6.5:2:1, and stirred evenly at 50°C for 6h; then, Li 6.4 La 3 Zr1.4 Nb 0.6 o 12 Inorganic electrolyte powder, stirred evenly, pressed to make the thickness 80 μm, vacuum dried at 80°C for 12 hours, to obtain a composite electrolyte functional layer;

[0115] Soak the above-mentioned composite electrolyte functional layer in methanol dopamine solution for 1 h, and then use a vacuum oven to dry in O 2 Dry at 80°C for 10 hours under the same conditions to obtain the intermediate functional layer;

[0116] 2. Combine PVDF-HFP, LiFSI, Li 6.4 La 3 Zr 1.4 Nb 0.6 o 12 Dissolve in DMF at a mass ratio of 3:1:0.5, stir for 10 hours until a uniform second slurry is formed, and scrape coat the second slurry on one side of the middle functional laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com