Polyimide composite material, composite film and preparation method thereof

A polyimide and composite material technology, applied in coatings and other directions, can solve the problems of large calcium-copper-titanium-oxygen particles and inability to achieve corona resistance effect, so as to improve dispersibility, reduce the probability of agglomeration, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The polyimide composite film of the present invention is prepared by the following method:

[0050] 1) Preparation of TiO 2 Nanotubes: add titanium dioxide powder (particle size 50 nanometers) and NaOH solution of 10M concentration in the autoclave according to the mass ratio of 1:5, seal it and put it into an oven at 140 ° C for 72 hours; The reaction product was moved to filter paper, washed with 0.1M hydrochloric acid and a large amount of deionized water, respectively, and filtered for use.

[0051] 2) In situ growth of gold nanoparticles: the rinsed, filtered TiO 2 The nanotube flocs were transferred to a suction filter with a peristaltic pump, and the titanium dioxide nanotubes were repeatedly washed 5 times with 0.01M chloroauric acid solution; The material was moved to a 100W UV lamp and illuminated for 10-15 minutes; then the flocs were naturally dried to obtain gold nanoparticle-modified titanium dioxide nanotube powder.

[0052] 3) Modification of silane c...

Embodiment 2

[0065] The process for preparing the polyimide composite film is basically the same as that in Example 1, with the only difference that: when the polyimide composite precursor is prepared by in-situ polymerization, the silane coupling agent-modified gold nanoparticles modified titania nanotubes occupy the same proportion as the polyimide composite precursor. 15% of the total mass of all dianhydride and diamine precursors.

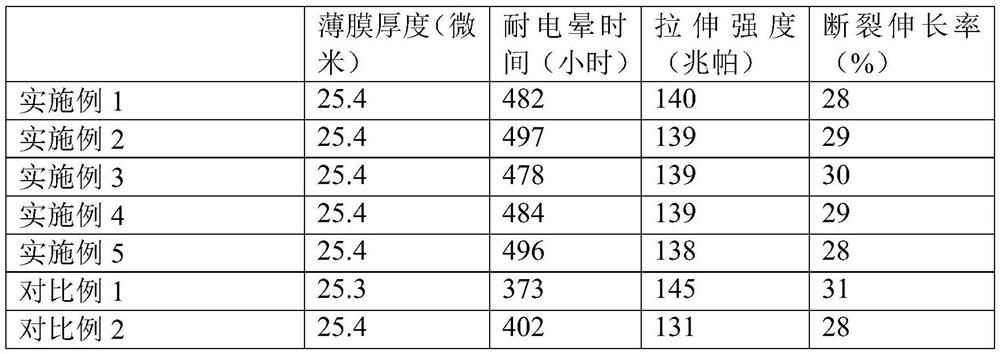

[0066] The properties of the composite films were also tested, and the results are shown in Table 1.

Embodiment 3

[0068] The process for preparing the polyimide composite film is basically the same as that in Example 1, with the only difference that: when the polyimide composite precursor is prepared by in-situ polymerization, the silane coupling agent-modified gold nanoparticles modified titania nanotubes occupy the same proportion as the polyimide composite precursor. 20% of the total mass of all dianhydride and diamine precursors.

[0069] The properties of the composite films were also tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com