Graphene composite powder material and preparation method thereof

A graphene composite and powder material technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unfavorable graphene material application, high degree of agglomeration and poor dispersion of graphene material powder, and achieve Excellent dispersibility and conductivity, few steps, easy to disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method one of graphene composite powder material, and this preparation method one comprises the following steps:

[0044] Step (11), the first polymer monomer, graphene material, and micro-nano structure material are added to water to obtain a mixed solution, wherein the mass ratio of the first polymer monomer, graphene material, and micro-nano structure material It is (0.01~1):(0.1~1):(5~1);

[0045] Step (12), adding a water-soluble initiator, reacting at a reaction temperature of 30°C to 100°C, and the reaction time is 1 hour to 10 hours, wherein the water-soluble initiator and the first polymer monomer The mass ratio is 1:10~1:100; and

[0046] Step (13), dry treatment to obtain the graphene composite powder material.

[0047] In step (11), the first polymer monomer, the graphene material, and the micro-nano structure material are mixed in advance, and the first polymer monomer can disperse the graphene mat...

Embodiment (1

[0076] Weigh 0.1g of polyvinylpyrrolidone, 1g of graphene material and 1g of conductive carbon black (super-P), and disperse them in 1L of deionized water, stir them evenly and spray dry them.

[0077] After measurement, the electrical conductivity of the obtained graphene composite powder material is ≥3500S / m, and the apparent density is 0.17g / cm 3 .

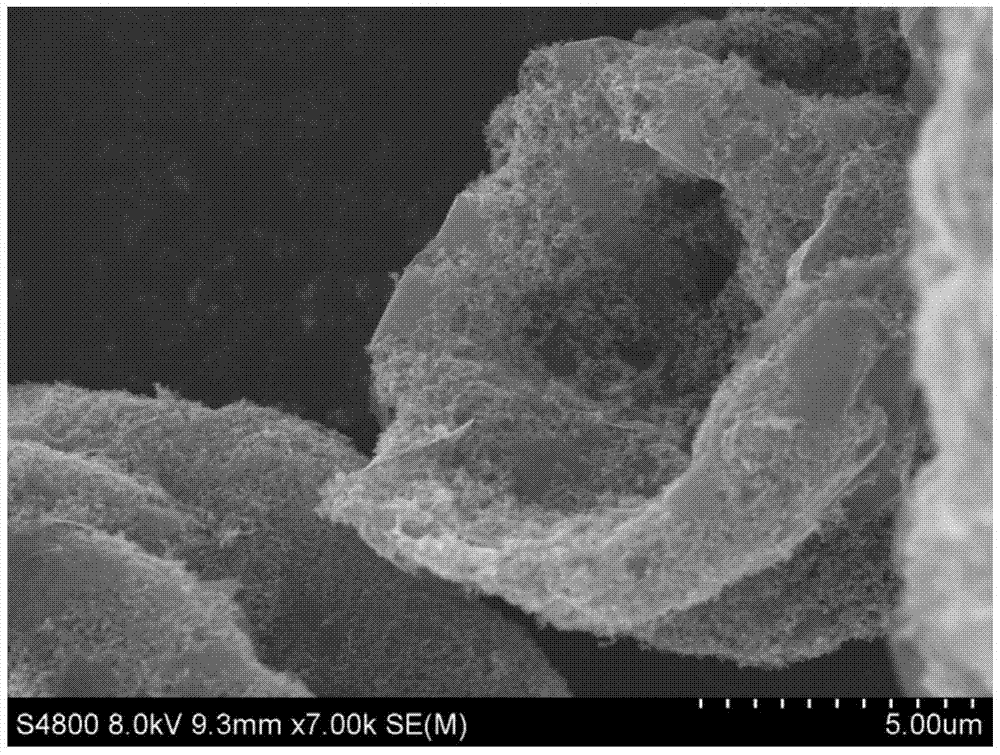

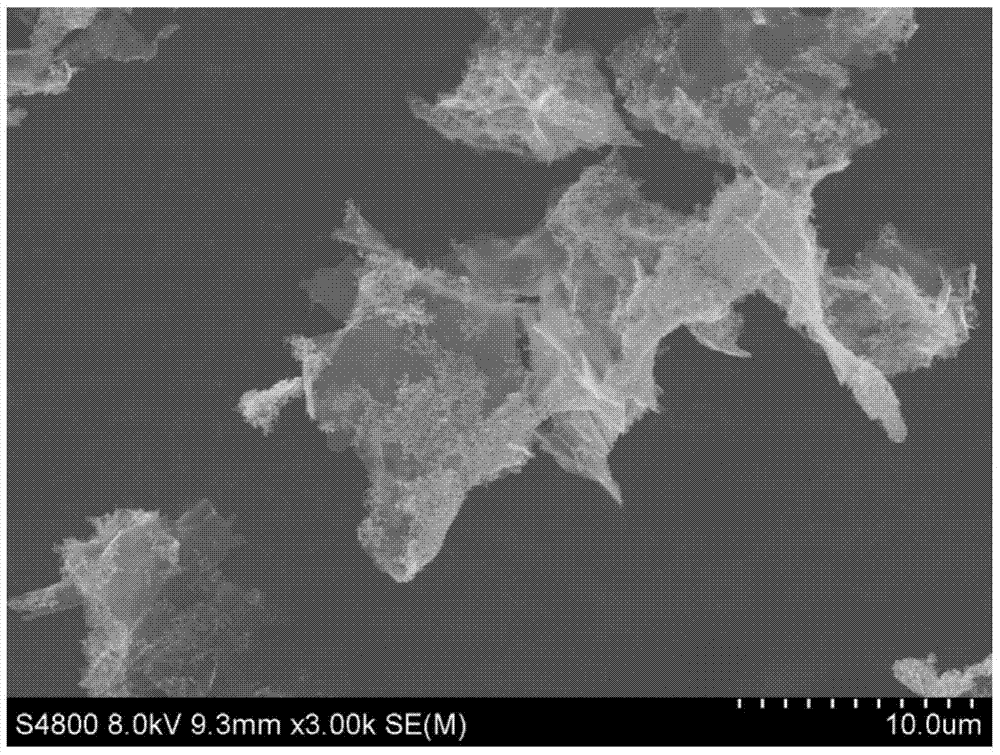

[0078] Such as figure 1 As shown, the dispersibility of the graphene composite powder material is good, and the conductive carbon black (super-P) is attached to the surface of the graphene material. The obtained graphene composite powder material is dispersed in water and then tested, such as figure 2 As shown, the dispersibility of the graphene composite powder material is better.

Embodiment (2

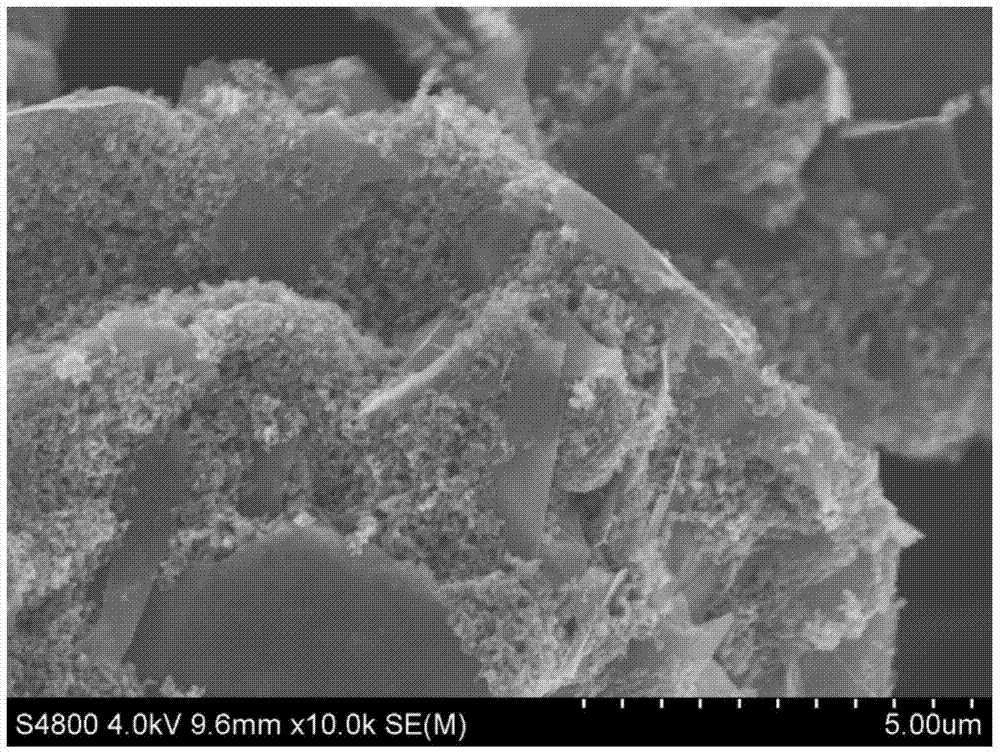

[0080] Weigh 0.01g of polyvinylpyrrolidone, 1g of graphene material and 0.1g of conductive carbon black (super-P), and disperse them in 1L of deionized water, stir them evenly and spray dry them.

[0081] After measurement, the electrical conductivity of the obtained graphene composite powder material is ≥3500S / m, and the apparent density is 0.15g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com