Covering emulsion having performance of improving coloring and covering power and preparation method thereof

A covering power and emulsion technology, applied in household appliances, applications, inks, etc., can solve the problems of increased cost of ink formulations, unsatisfactory covering effect, etc., achieve good covering power and tinting power, and is conducive to the uniformity and stability of emulsion size , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

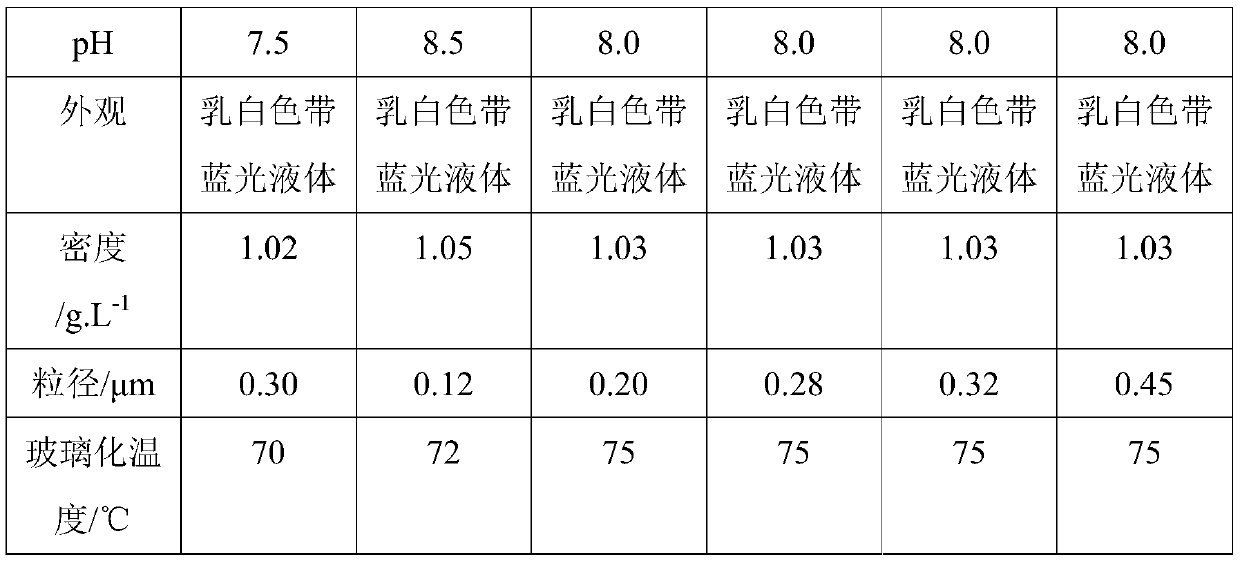

[0029] Embodiment 1, a kind of covering emulsion with improved coloring and hiding power performance

[0030] The concealing emulsion with improved coloring and hiding power properties includes the following components and their mass parts: 5 parts of modified polymers, 25 parts of styrene, 10 parts of acrylic acid, 2 parts of nonionic emulsifier, emulsified composition 1 part, 0.1 part of initiator and 40 parts of deionized water; the nonionic emulsifier is made up of coconut oil fatty acid diethanolamide and alkyl glucoside in a mass ratio of 8:3; the emulsifying composition consists of lauryl Sodium sulfate and sorbitan oleate are composed in a mass ratio of 4:1; the initiator is ammonium persulfate.

[0031] The preparation method of described modified polymer is:

[0032] (1) Premix polyetheramine with an average molecular weight of 400 and epoxy resin at a mass ratio of 90:16, and react at 55°C for 1 hour to obtain a polymer;

[0033] (2) Premix the polymer obtained in...

Embodiment 2

[0038] Embodiment 2, a kind of covering emulsion with improved coloring and hiding power performance

[0039] The concealing emulsion with improved coloring and hiding power performance includes the following components and their mass parts: 10 parts of modified polymer, 32 parts of styrene, 15 parts of acrylic acid, 5 parts of nonionic emulsifier, emulsified composition 3 parts, 0.3 parts of initiator and 50 parts of deionized water; Described nonionic emulsifier is made up of coconut oil fatty acid diethanolamide and alkyl glucoside by mass ratio 10:2; Described emulsifying composition is made up of lauryl Sodium sulfate and sorbitan oleate are composed of 8:1 in mass ratio; the initiator is ammonium persulfate.

[0040] The preparation method of described modified polymer is:

[0041] (1) Premix polyetheramine with an average molecular weight of 400 and epoxy resin at a mass ratio of 105:12, and react at 65°C for 3 hours to obtain a polymer;

[0042] (2) Premix the polyme...

Embodiment 3

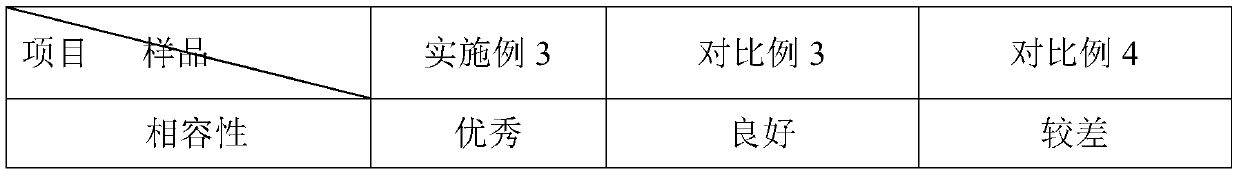

[0047] Embodiment 3, a kind of covering emulsion with improved coloring and hiding power performance

[0048] The concealing emulsion with improved coloring and hiding properties includes the following components and their mass parts: 7 parts of modified polymers, 30 parts of styrene, 13 parts of acrylic acid, 4 parts of nonionic emulsifiers, emulsified composition 2 parts, 0.2 part of initiator and 45 parts of deionized water; Described nonionic emulsifier is made up of coconut oil fatty acid diethanolamide and alkyl glucoside in mass ratio 9:2; Described emulsifying composition is made up of lauryl Sodium sulfate and sorbitan oleic acid ester are composed in a mass ratio of 6:1; the initiator is ammonium persulfate.

[0049] The preparation method of the modified polymer is:

[0050] (1) Premix polyetheramine with an average molecular weight of 400 and epoxy resin at a mass ratio of 100:15, and react at 60°C for 2 hours to obtain a polymer;

[0051] (2) Premix the polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com