Polyimide film and preparation method thereof, and base film of radio frequency flexible printed circuit

A technology of polyimide film and polyamic acid resin, which is applied in the direction of printed circuit, printed circuit, circuit substrate material, etc., can solve the problems of liquid crystal phase change easily, high frequency signal transmission loss, high dielectric loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

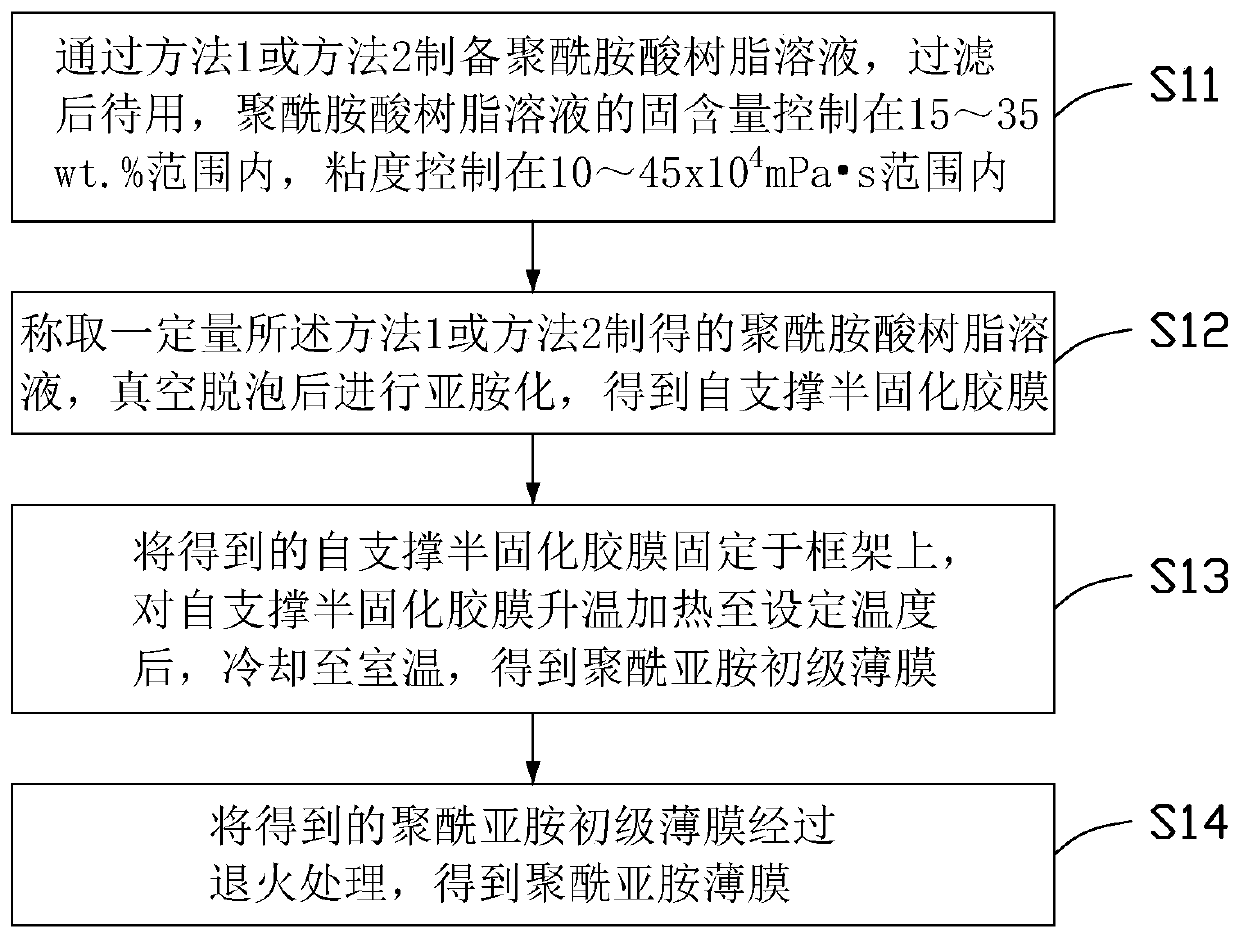

[0036] see figure 1 , figure 1 It is a schematic flow diagram of the preparation method of the polyimide film in one embodiment of the present invention, specifically comprising the following steps:

[0037] S11, prepare the polyamic acid resin solution, filter and set aside, the solid content of the polyamic acid resin solution is controlled within the range of 15-35wt.%, and the viscosity is controlled at 10-45x10 4 Within the range of mPa·s;

[0038] S12, weighing a certain amount of polyamic acid resin solution, performing imidization after vacuum defoaming, to obtain a self-supporting semi-cured film;

[0039] S13, fixing the obtained self-supporting semi-cured adhesive film on the frame, heating the self-supporting semi-cured adhesive film to a set temperature, and then cooling to room temperature to obtain a polyimide primary film;

[0040] S14, annealing the obtained primary polyimide film to obtain a polyimide film.

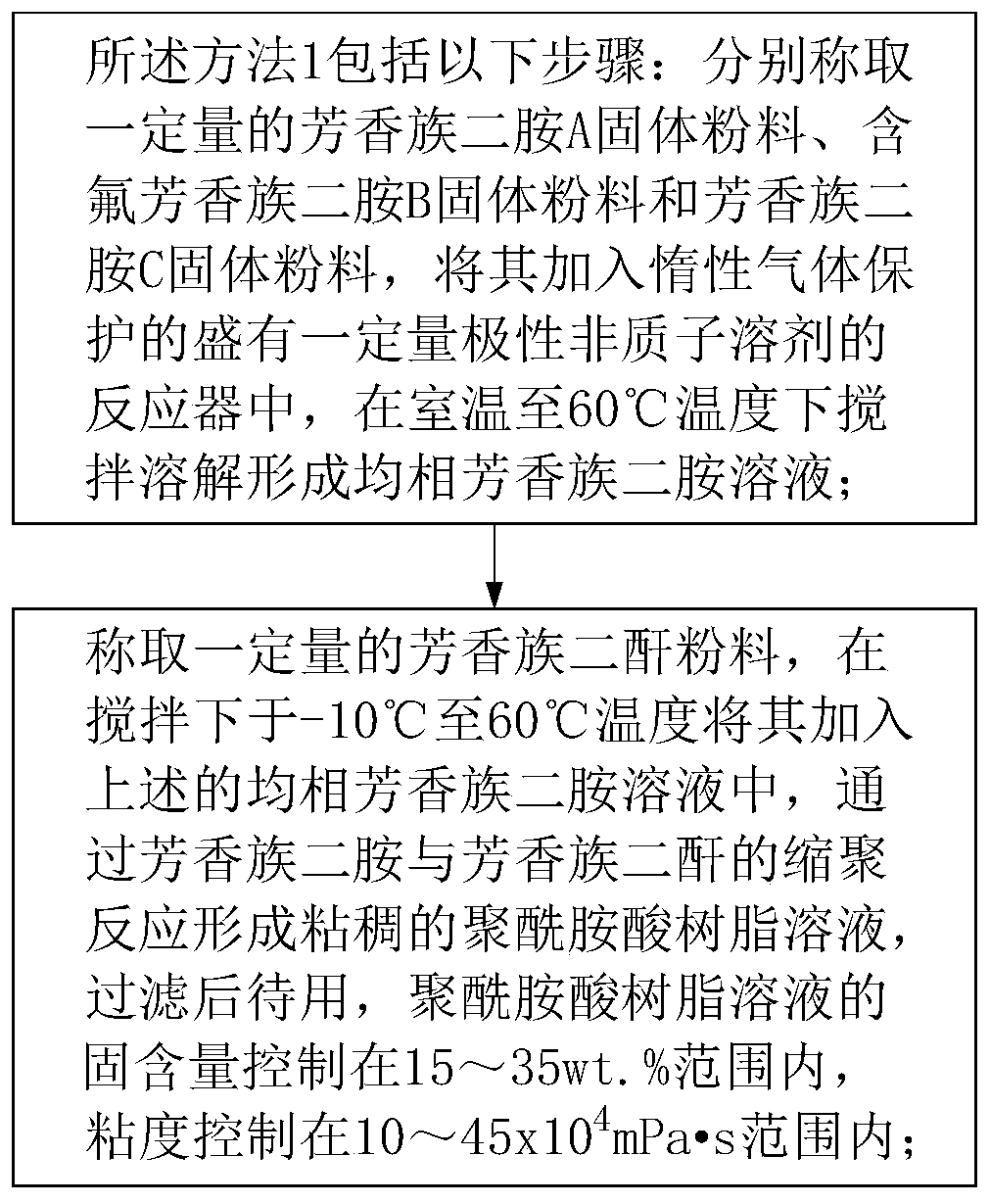

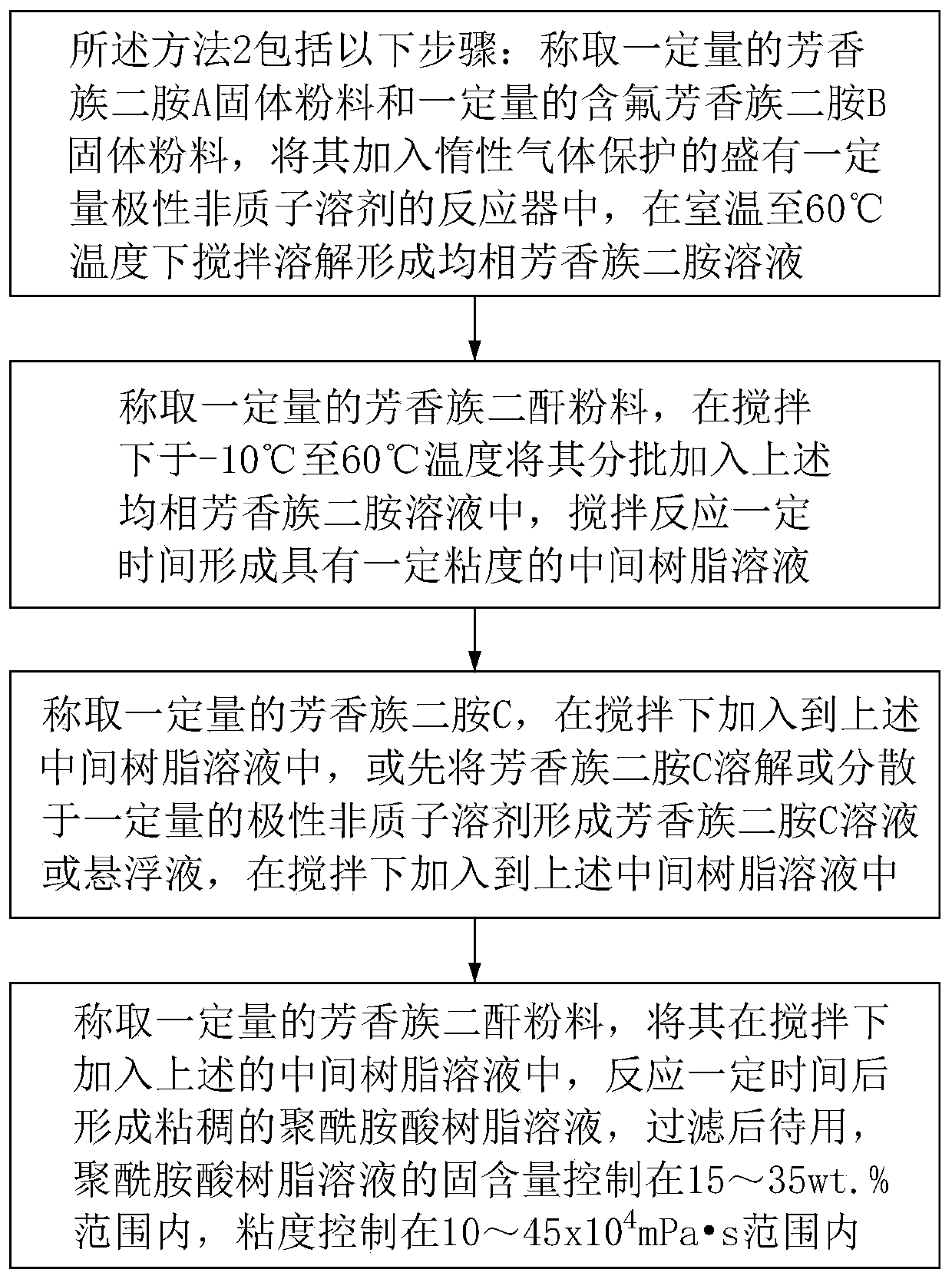

[0041] see figure 2 , in one embodiment, th...

Embodiment 1

[0070] Add 1.3g of 4,4'-diaminodiphenyl ether (4,4-ODA) solid powder, 30.2g of bis(2-trifluoromethyl-4-amino Phenoxy)benzene (6FAPB) solid powder and 200ml N,N-dimethylformamide solvent, stirring and dissolving at 35°C to form a homogeneous aromatic diamine solution; weigh 15.3g pyrene dianhydride (PMDA ) solid powder, add it to the homogeneous aromatic diamine solution in batches under stirring, stir and react at 35°C for 1-24h to form an intermediate resin solution; weigh 5.5g p-phenylenediamine (PDA) solid powder material, add it to the above-mentioned intermediate resin solution under stirring; weigh 11.4g of pyrene dianhydride (PMDA) solid powder, add it to the above-mentioned intermediate resin solution under stirring, and form after a certain period of reaction Viscous polyamic acid resin (PAA) solution.

[0071] Weigh 1.1g PMDA, dissolve it in 16.3ml N,N-dimethylformamide solvent, add it to the above-mentioned polyamic acid resin solution in batches under stirring, an...

Embodiment 2

[0074] Add 2.6g of 4,4'-diaminodiphenyl ether (4,4-ODA) solid powder, 28.1g of bis(2-trifluoromethyl-4- Aminophenoxy)benzene (6FAPB) solid powder and 200ml N,N-dimethylformamide solvent, stirred and dissolved at 35°C to form a homogeneous aromatic diamine solution; weigh 28.5g pyrene dianhydride ( PMDA) solid powder, add it in batches to the homogeneous aromatic diamine solution under stirring, stir and react at 35°C for 1-24h to form an intermediate resin solution; weigh 5.6g of p-phenylenediamine (PDA) solid Powder, dissolve it in 23.6mL DMF solvent, add it to the above-mentioned intermediate resin in batches under stirring, react for 1-24h under stirring to form a viscous polyamic acid resin solution, and the solid content of the resin is controlled at 23wt.%, the viscosity is controlled at 10×10 4 mPa s.

[0075] Take by weighing sufficient amount of above-mentioned polyamic acid resin solution (PAA) solution according to the selected support size and coating thickness, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com