Antifouling titanium alloy material based on bionic super-smooth surface and preparation method and application thereof

A titanium alloy, substrate surface technology, applied in surface reaction electrolytic coatings, devices for coating liquids on surfaces, electrolytic coatings, etc., can solve problems such as biocide marine environmental hazards, genetic variation of marine organisms, and threats to human health, etc. Achieve significant anti-bacterial adhesion, reduce the amount of adhesion, and prevent a large amount of loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

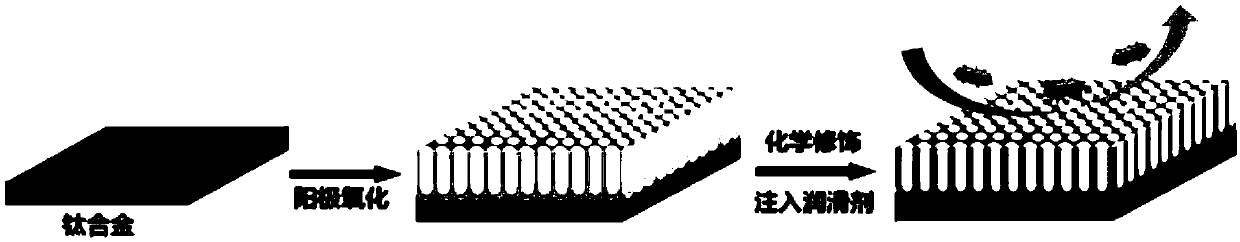

[0030] As an aspect of the technical solution of the present invention, it relates to a method for preparing an antifouling titanium alloy material based on a bionic super-slip surface, such as figure 1 Shown, described preparation method comprises:

[0031] Provide titanium alloy substrate;

[0032] The titanium alloy substrate is treated with an anodic oxidation method, and a nanostructure layer arranged in an array is formed on the surface of the titanium alloy substrate, and the nanostructure layer includes nanopores or nanotubes, wherein the diameter of the nanopores is 10- 30nm, the depth is 50-200nm, the diameter of the nanotube is 30-200nm, and the depth is 200-600nm;

[0033] Chemical modification of titanium alloy substrate with nanostructure layer with fluorosilane modifier;

[0034] And, a lubricant is applied to the surface of the chemically modified titanium alloy substrate to obtain an antifouling titanium alloy material based on a bionic super-slip surface. ...

Embodiment 1

[0071] The process of the bionic super-slippery surface prepared on the titanium alloy surface in this embodiment is as follows: figure 1 As shown, including anodic oxidation, chemical modification, and lubricant injection, the specific preparation steps are:

[0072] Pretreatment of titanium sheet: use 30 × 20 × 3mm Ti-6Al-4V titanium alloy as the substrate, use 400 mesh, 800 mesh, 1200 mesh, 2000 mesh, 3000 mesh SiC sandpaper to polish it, and then in absolute ethanol and deionized water for 20 minutes to remove oil stains.

[0073] Preparation of TiO by Anodic Oxidation 2 Nanostructure: Pretreated Ti-6Al-4V titanium alloy as anode, platinum sheet as cathode, 0.5M H 3 PO 4 The mixed solution with 0.14M NaF is used as the electrolyte, and a voltage of 10V is applied at 25°C for anodic oxidation, taken out after 30min, and dried at 80°C for use.

[0074] Chemical modification: prepare ethanol solution of 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane as the modification solu...

Embodiment 2

[0078] The process of the bionic super-slippery surface prepared on the titanium alloy surface in this embodiment is as follows: figure 1 As shown, including anodic oxidation, chemical modification, and lubricant injection, the specific preparation steps are:

[0079] Pretreatment of titanium sheet: use 30 × 20 × 3mm Ti-6Al-4V titanium alloy as the substrate, use 400 mesh, 800 mesh, 1200 mesh, 2000 mesh, 3000 mesh SiC sandpaper to polish it, and then in absolute ethanol and deionized water for 20 minutes to remove oil stains.

[0080] Preparation of TiO by Anodic Oxidation 2 Nanostructure: Pretreated Ti-6Al-4V titanium alloy as anode, platinum sheet as cathode, 0.5M H 3 PO 4 The mixed solution with 0.14M NaF is used as the electrolyte, and a voltage of 15V is applied at 25°C for anodic oxidation, taken out after 30min, and dried at 80°C for use.

[0081] Chemical modification: prepare ethanol solution of 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane as the modification solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com