Multi-rotary hydraulic valve

A rotary valve technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of the difficulty of special non-standard hydraulic motors, unfavorable promotion and application, long manufacturing period, etc., to avoid risks, easy to operate and labor-saving , the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

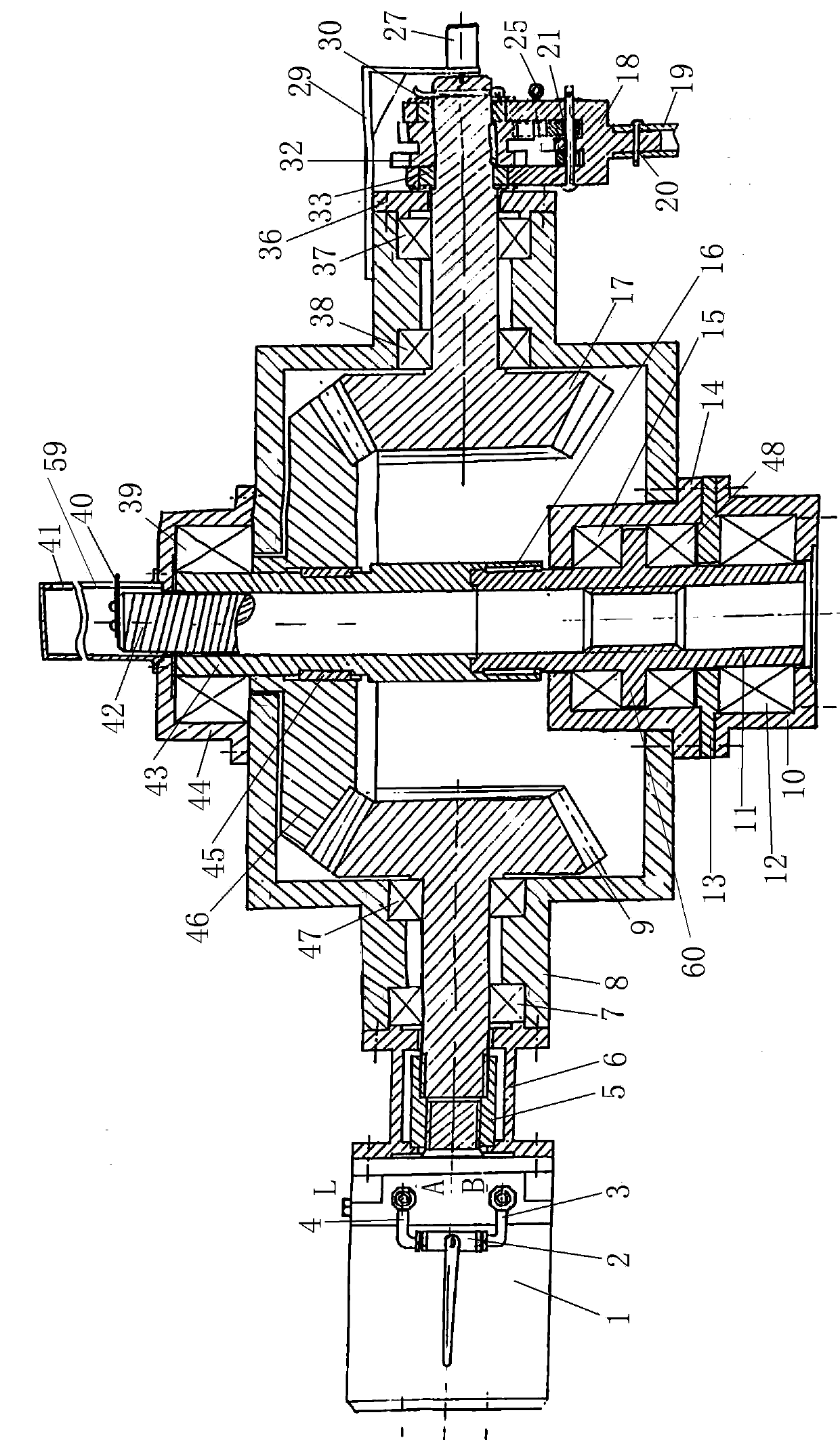

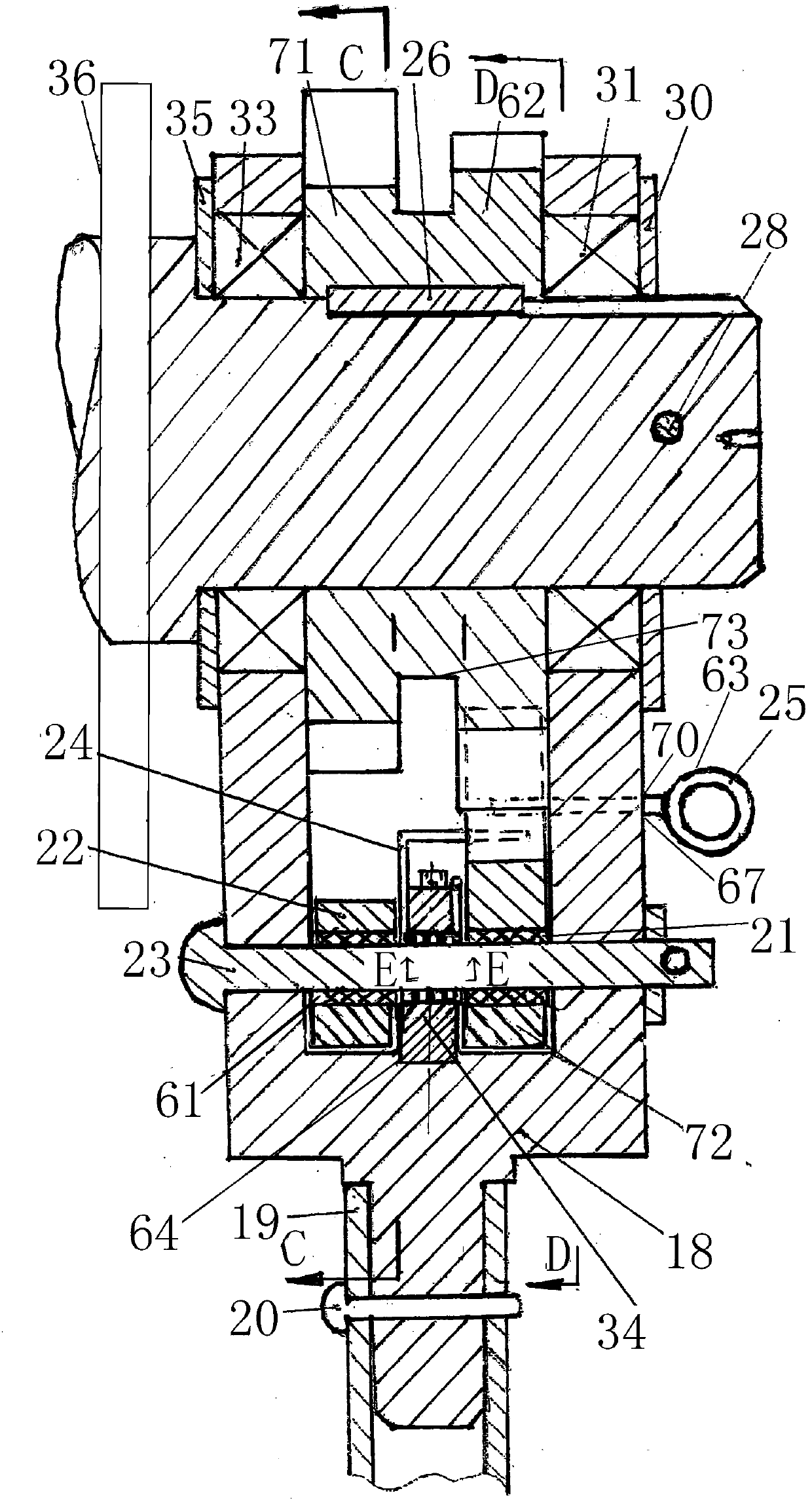

Embodiment 1

[0065] A multi-rotary hydraulic valve has a hydraulic motor 1 . The hydraulic motor 1 is a known standard series of products, which can be selected flexibly to ensure its matching, which can shorten the delivery cycle of hydraulic valves and reduce product prices, facilitate the standardization and serialization of this product, and overcome the hydraulic pressure of known multi-turn hydraulic valves. Direct motor drive is theoretically feasible and has outstanding advantages, but the design and manufacture are difficult, the construction period is long, the processing cost is high, and the degree of standardization is low, which is not conducive to the promotion and application of the superior technology of multi-turn hydraulic valves.

[0066] I have authorized three patents, the patent number is 201210158229.9 a multi-rotary hydraulic valve, 200610135071.8 rotary hydraulic valve, 200610135142.4 rotary hydraulic valve, the required hydraulic motor needs to be customized separ...

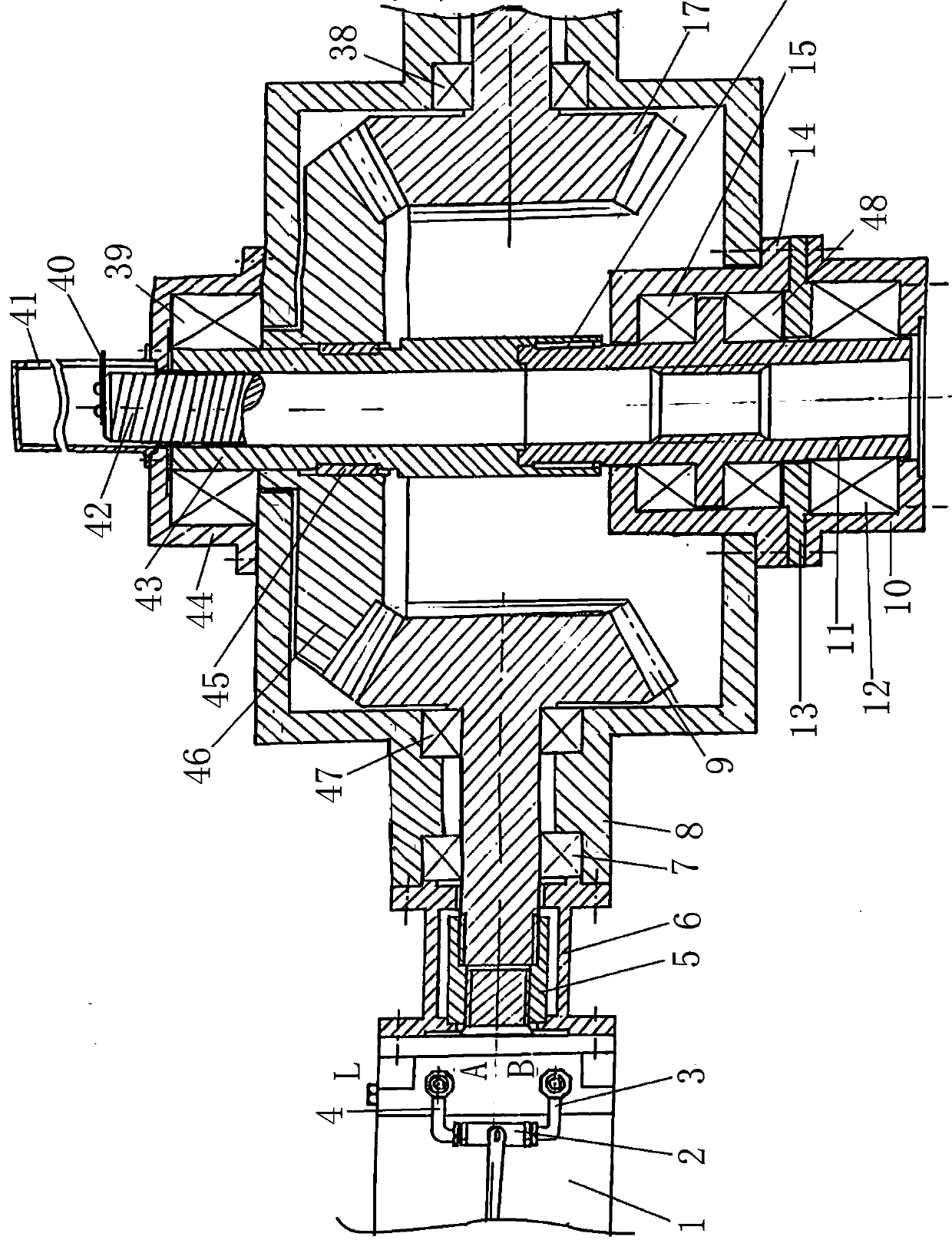

Embodiment 2

[0151] Embodiment 2 is basically the same as Embodiment 1, except that the bright stem valve is replaced by a dark stem valve, and the dark stem valve drives the valve stem (upper solid valve stem) 53 to rotate instead of moving up and down.

[0152] The lifting valve stem 42 , the valve driving bushing 43 and the lifting valve stem nut 11 in Embodiment 1 are replaced by a dark rod valve driving valve stem 53 .

[0153] The vertically arranged dark rod valve driving valve rod 53 upper end is fixedly connected with the large bevel gear 46 inner hole with the dark rod valve driving valve rod coupling key 76.

[0154] The lower end of the hidden rod valve driving valve stem 53 is provided with a lower rolling bearing for the valve stem, which is fixedly supported on the inner side of the gear box body 8 by the lower rolling bearing seat 54 of the valve stem.

[0155] Valve stem lower rolling bearing seat 54 bottom stretches out gear box body 8 edges and fixes.

[0156] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com