Piezocapacitance and piezoresistance coupled proximity sensing and contact force sensor

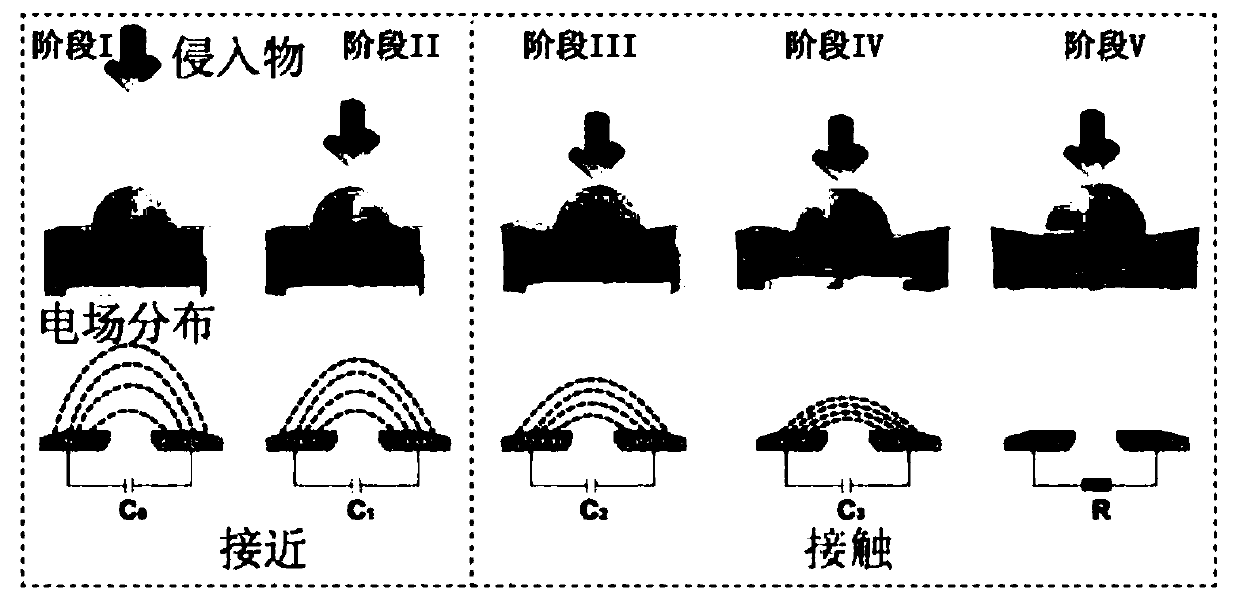

A sensor and contact force technology, which is applied in the measurement, instrument, and measurement force of the property force of piezoresistive materials. It can solve the problems of difficult to break through in response speed, complex measurement circuit, and parasitic capacitance, so as to increase contact perception. function, the effect of expanding the test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

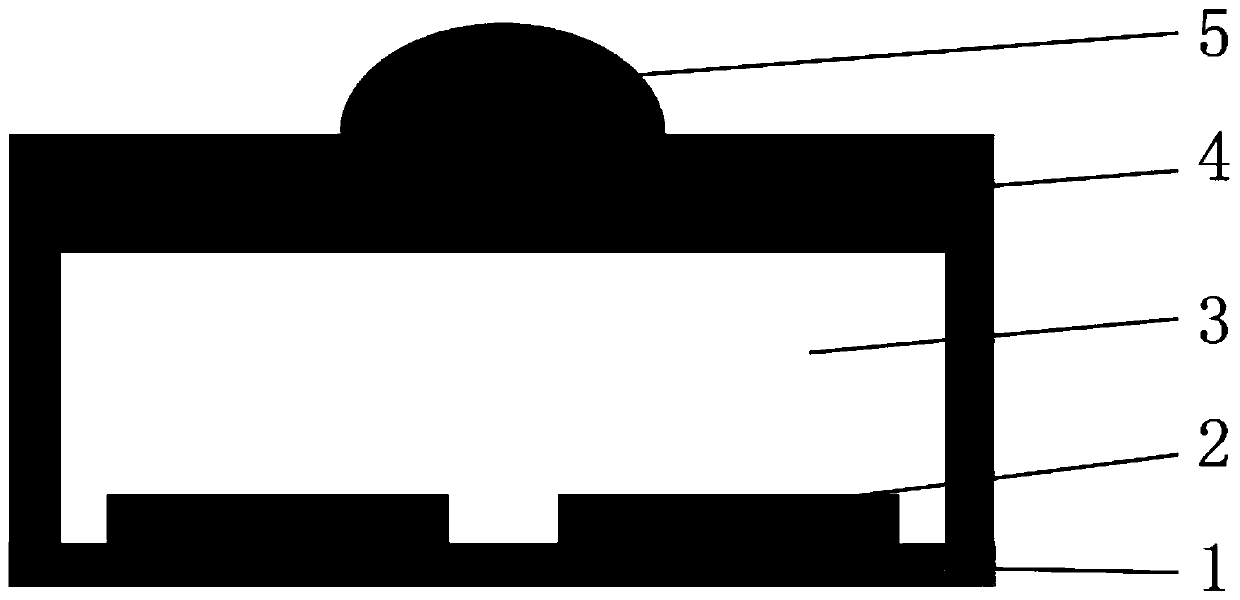

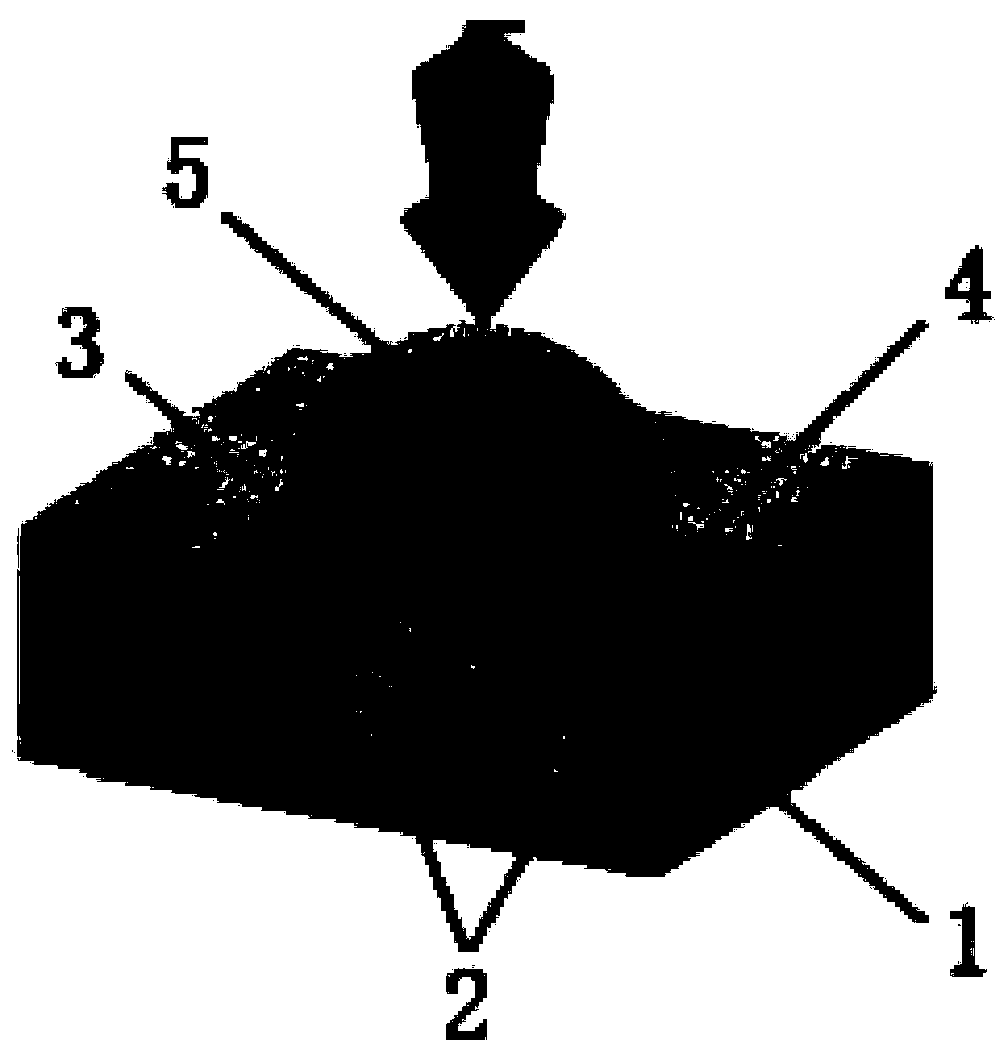

[0018] see Figure 1-4 Describe this embodiment, a proximity sensing and contact force sensor coupled with piezocapacitance and piezoresistive, which includes a flexible substrate 1, coplanar electrodes 2, piezoresistive elastic body 4 and surface protrusions 5, the flexible substrate 1 Located at the bottom, the coplanar electrode 2 is disposed on the flexible substrate 1, the piezoresistive elastomer 4 is a cavity structure, and the piezoresistive elastomer 4 is disposed above the flexible substrate 1 and the coplanar electrode 2, The piezoresistive elastomer 4 forms an air cavity 3 in the area enclosed by the flexible substrate 1, and the surface protrusion 5 is arranged on the upper surface of the piezoresistive elastomer 4. The piezoresistive elastomer 4 adopts low-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com