Structure test detection method based on three-dimensional laser scanning technology

A three-dimensional laser and structural testing technology, applied in the testing of machine/structural components, optical instrument testing, measuring devices, etc., can solve the problems of insufficient observation accuracy and lack of observation, and achieve the effect of avoiding error accumulation and improving density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

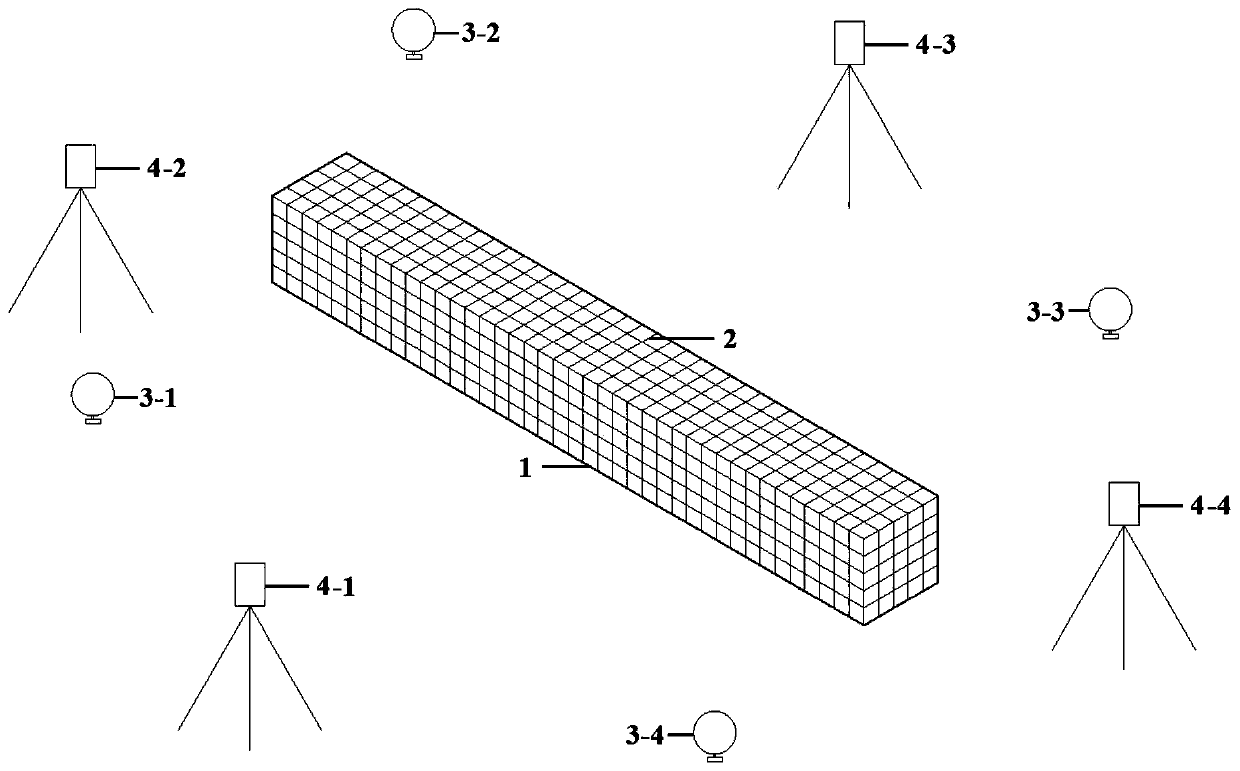

[0029] as attached figure 1 Shown, be a kind of structure test detection method based on three-dimensional laser scanning technology of the present invention, it comprises the following contents and steps:

[0030] a. Test object 1 is a reinforced concrete beam. Paint all the surface of test object 1 white with lime, and then draw black straight lines 2 and 2 on the surface of test object 1 with a pencil, which are perpendicular to each other and have equal spacing. The surface of the test object 1 is clearly divided into different square grid-like areas, and the size of the grid-like area can be determined according to the degree of detail of the observation. In this embodiment, the side length of the square grid-like area is 10 cm, which is convenient Observing and pinpointing developmental patterns of displacement, deformation, cracking and failure in different regions of the structure;

[0031] b. During the test, the test object 1 is placed at a certain distance above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com