Experimental method for quickly improving titanium alloy hardness at normal temperature

An experimental method and technology for titanium alloys, applied in the field of titanium alloys, can solve the problems of time-consuming, complex processing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] An experimental method for rapidly increasing the hardness of a titanium alloy at normal temperature comprises the following steps.

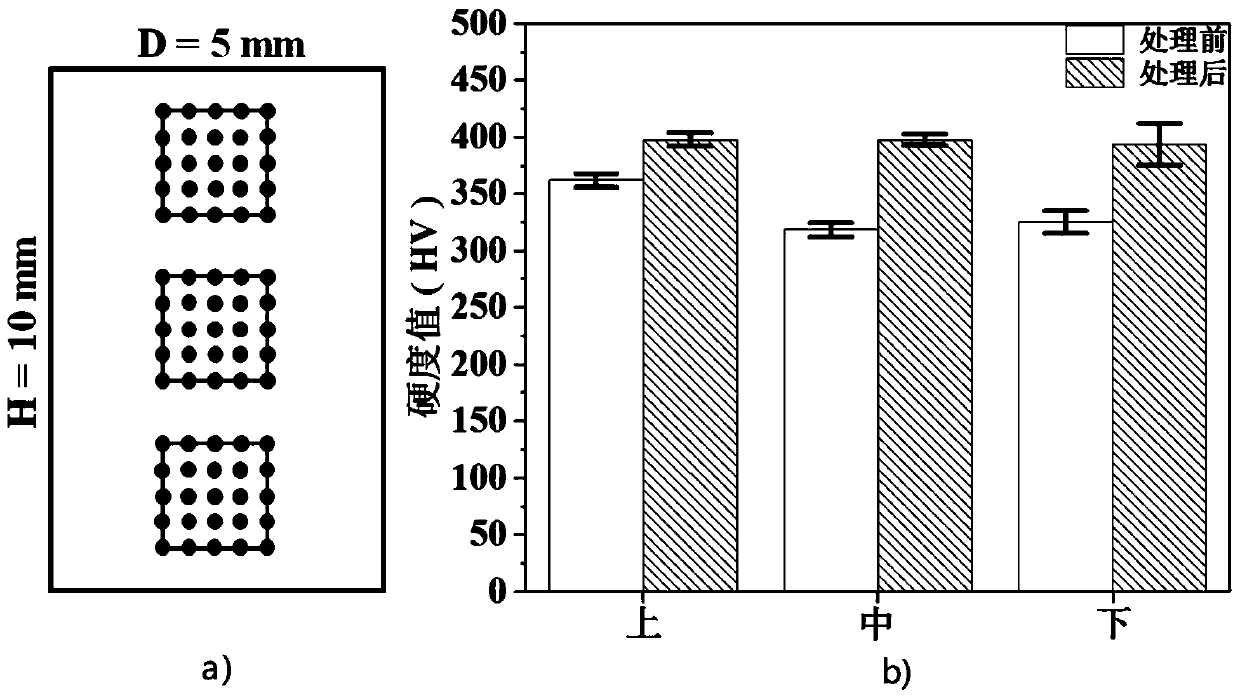

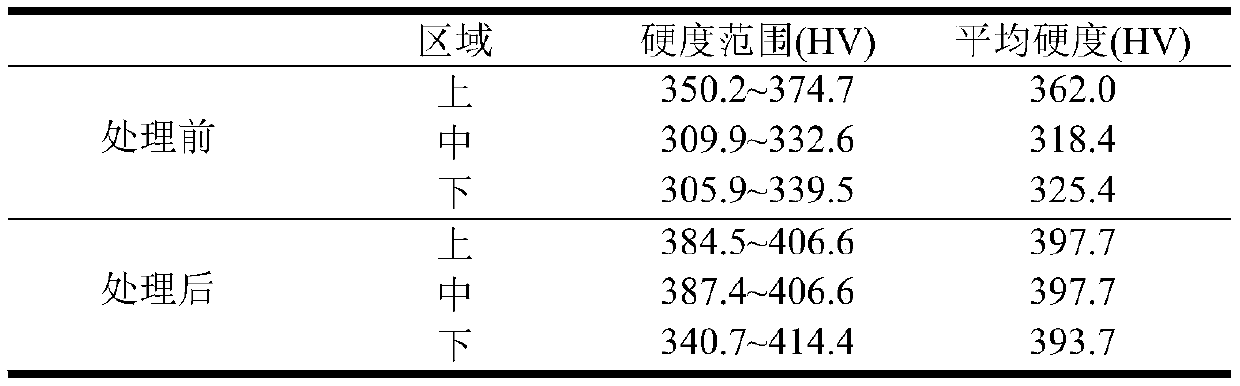

[0023] S1. Taking titanium alloy TC11 as an example, the rod-shaped titanium alloy TC11 raw material is prepared into a Φ5×10mm cylindrical sample by wire cutting method, and the surface oxide layer is removed by sandpaper grinding, and the sample is placed between the two electrodes of the electric shock treatment equipment.

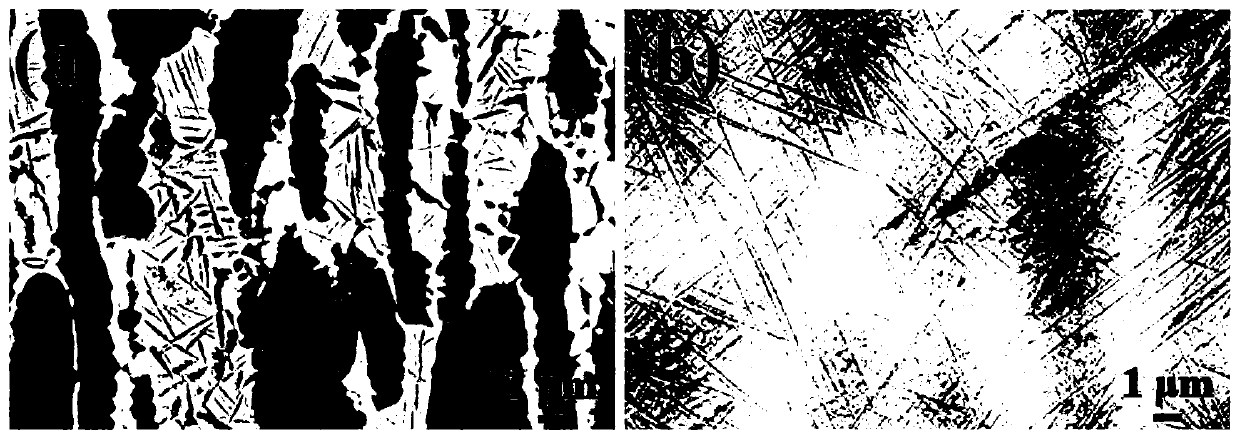

[0024] S2. Set the parameters of electric shock treatment: front-end input current amplitude 70A, action time 0.12s, conduct electric shock treatment on the sample, after the sample is cooled to room temperature, remove the surface oxide layer by sandpaper grinding, and the sample after electric shock treatment The metallographic samples were cut along the central axis by wire cutting and ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com