A method and system for continuously predicting phosphorus content in converter molten pool

A technology of phosphorus content and molten pool, applied in the field of metallurgy, can solve the problem of low hit rate of phosphorus content at the end of converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

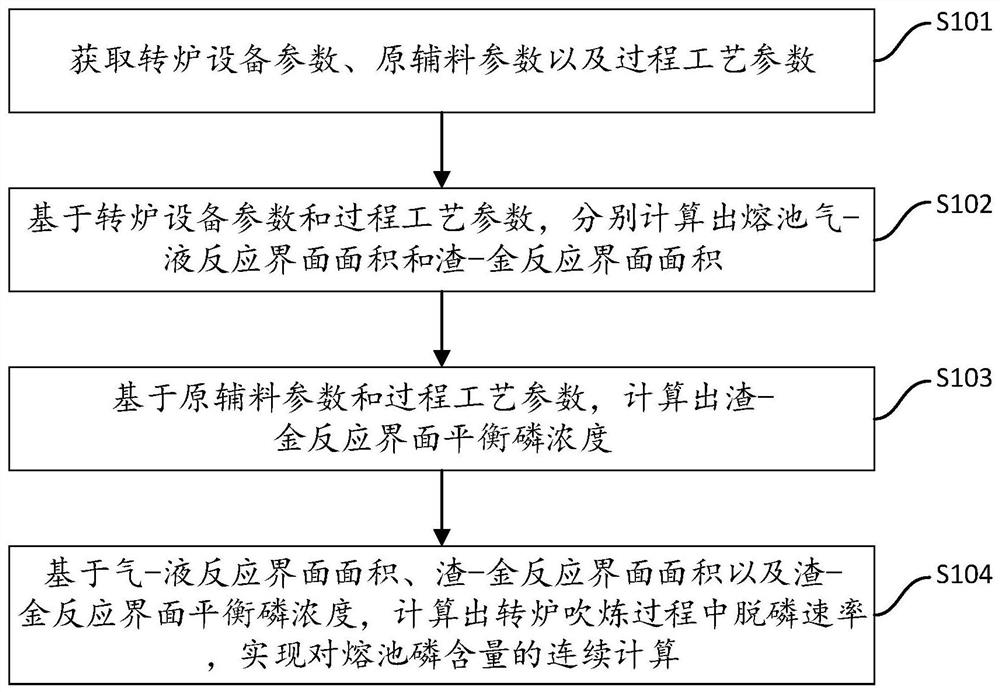

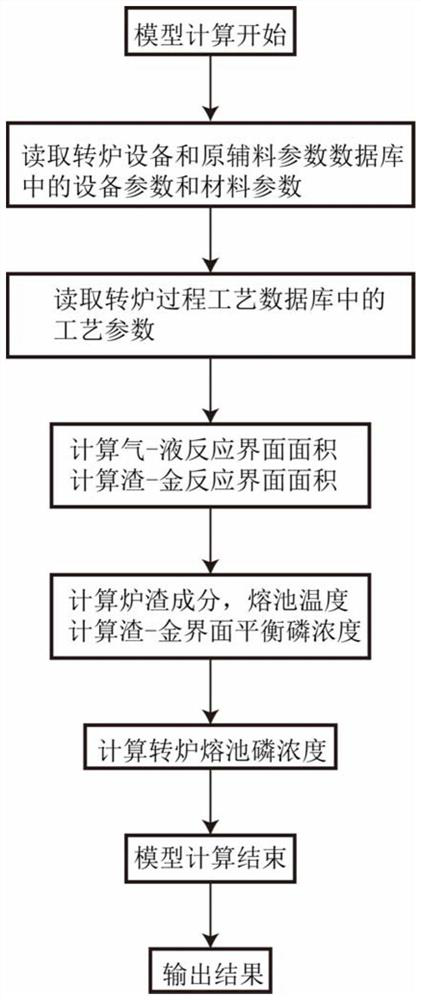

[0087] see figure 1 and figure 2 , the present embodiment provides a method for continuously predicting the phosphorus content in the converter molten pool, the method comprising the following steps:

[0088] S101, obtaining converter equipment parameters, raw and auxiliary material parameters, and process parameters;

[0089] It should be noted that, in this embodiment, converter equipment parameters and raw and auxiliary material parameters are stored in the equipment and raw and auxiliary material parameter database; process process parameters are stored in the process process parameter database; when storing, the data is stored in In the corresponding database; when used, the corresponding data is read from the database through the reading system.

[0090] Among them, converter equipment parameters include converter body size information and oxygen lance parameter information; wherein, converter body size information includes converter height, molten pool depth, convert...

no. 2 example

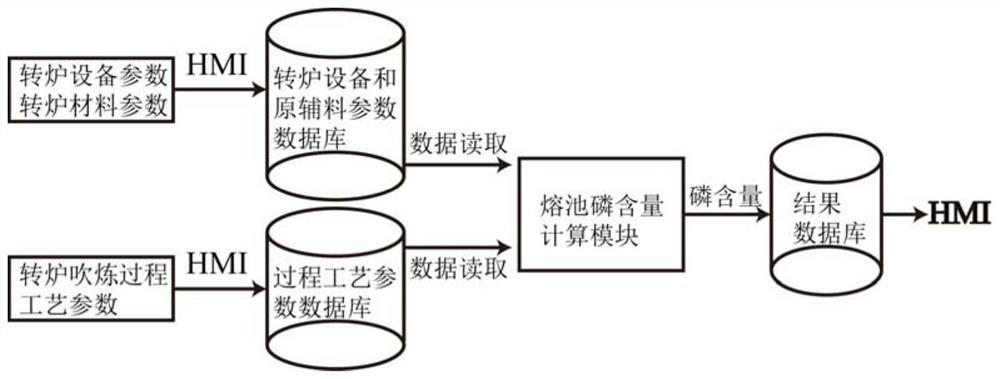

[0133] see image 3 , the present embodiment provides a system for continuously predicting the phosphorus content in the converter bath, the system comprising:

[0134] Equipment and raw and auxiliary material parameter database, used to store converter equipment parameters and raw and auxiliary material parameters; wherein, the converter equipment parameters include converter body size information and oxygen lance parameter information; wherein, the converter body size information includes converter height, molten pool The depth and the radius of the converter molten pool; the oxygen lance parameter information includes the number of holes in the oxygen lance nozzle, the angle of the oxygen lance nozzle and the diameter of the throat; the raw and auxiliary material parameters include the name of scrap steel and slagging material used in the converter blowing process and ingredients;

[0135] The process parameter database is used to store the process process parameters, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com