Fuel cell system and standby control method thereof

A fuel cell system and control method technology, applied in the direction of fuel cell control, fuel cells, fuel cell additives, etc., can solve the problems of not considering the durability and feasibility of air compressors, so as to shorten the experience time, avoid backflow, Effect of improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

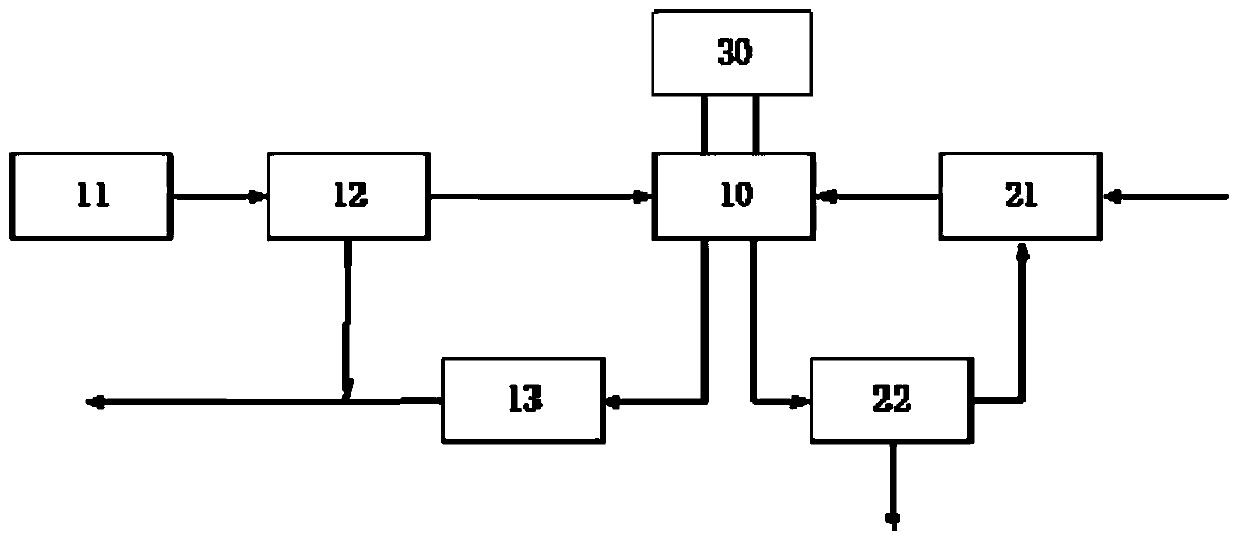

Examples

Embodiment

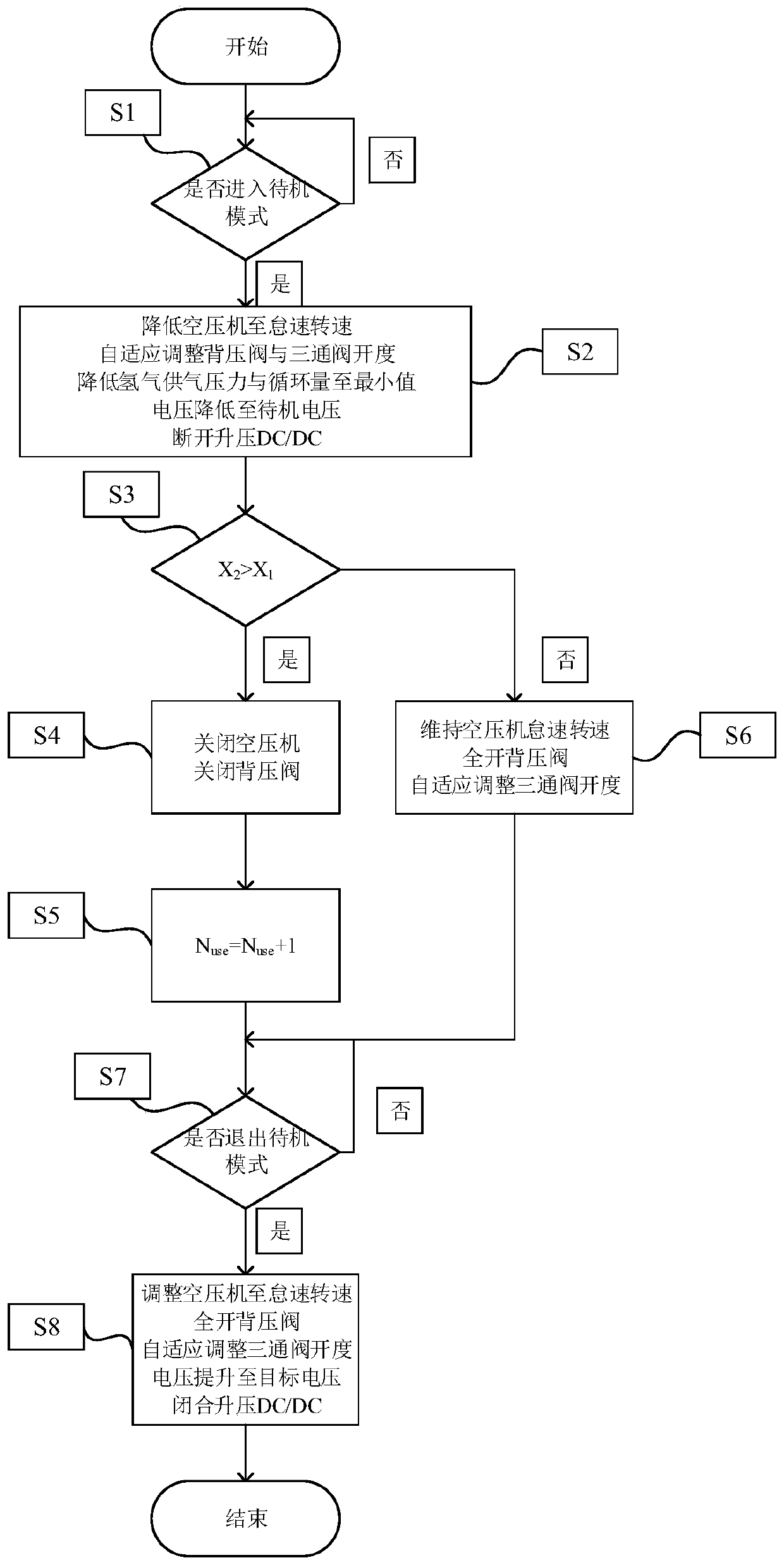

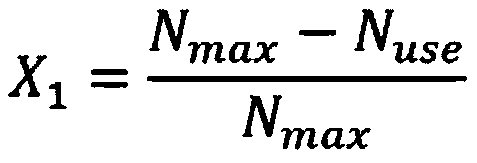

[0068] This embodiment provides a standby control method of a fuel cell system, which includes the following steps:

[0069] Step S1, it is judged whether the fuel cell system has received an instruction to enter the standby mode, if an instruction to enter the standby mode is received, step S2 is executed; if an instruction to enter the standby mode is not received, step S1 is executed;

[0070] Step S2: After the fuel cell system receives the instruction to enter the standby mode, it reduces the air compressor to its idle speed, adaptively adjusts the opening of the back pressure valve and the three-way valve, so that the air supply conditions for the cathode chamber of the fuel cell stack meet Fuel cell power consumption demand; adjust the hydrogen gas supply pressure and circulation volume to the minimum according to the air supply status; after the fuel cell stack voltage is pulled down to the idle voltage with a small current, disconnect the fuel cell stack and boost DC / DC Co...

Embodiment 1

[0109] (3) Compared with Example 1, the standby control method of the fuel cell system provided by Comparative Example 2 does not take into account the life factor of the air compressor. The standby mode of the fuel cell system is relatively single, and the use of the fuel cell system The service life has an adverse effect, which shows that embodiment 1 takes into account the start and stop service life of the air compressor, which is more conducive to the actual use of the car;

[0110] (4) Compared with Example 1, the standby control method of the fuel cell system provided by Comparative Example 3 maintains the open circuit voltage of the fuel cell at the voltage required for standby in the standby state, and the catalyst is not activated at this voltage, so The performance of the fuel cell stack is inferior to that of the first embodiment, which shows that the idling voltage adopted in the first embodiment is beneficial to improve the performance of the fuel cell stack.

[0111]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com