Fuel cell gas supply device and control method thereof

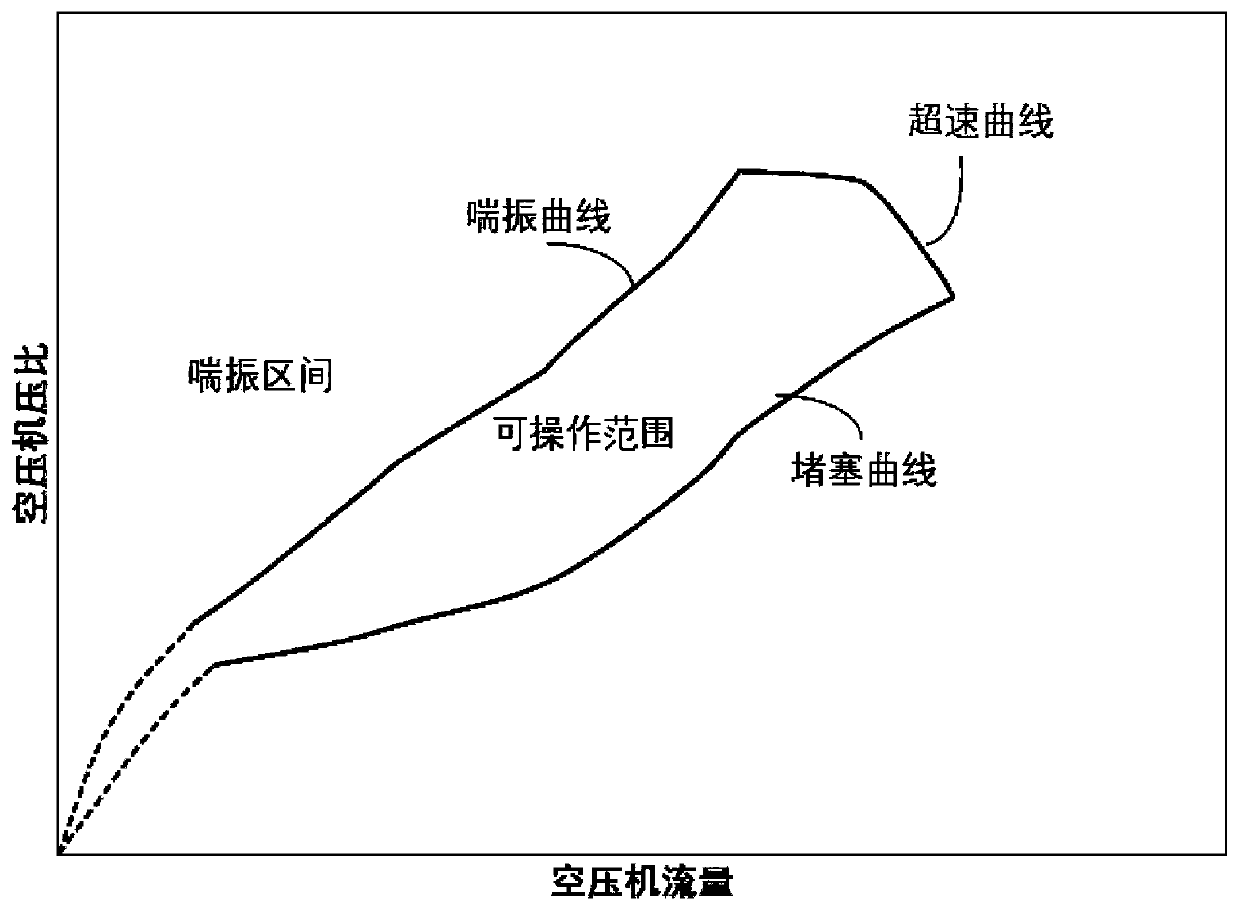

A gas supply device, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, electrical components, etc., to achieve good control effect, fast and precise regulation, and solve the effect of surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

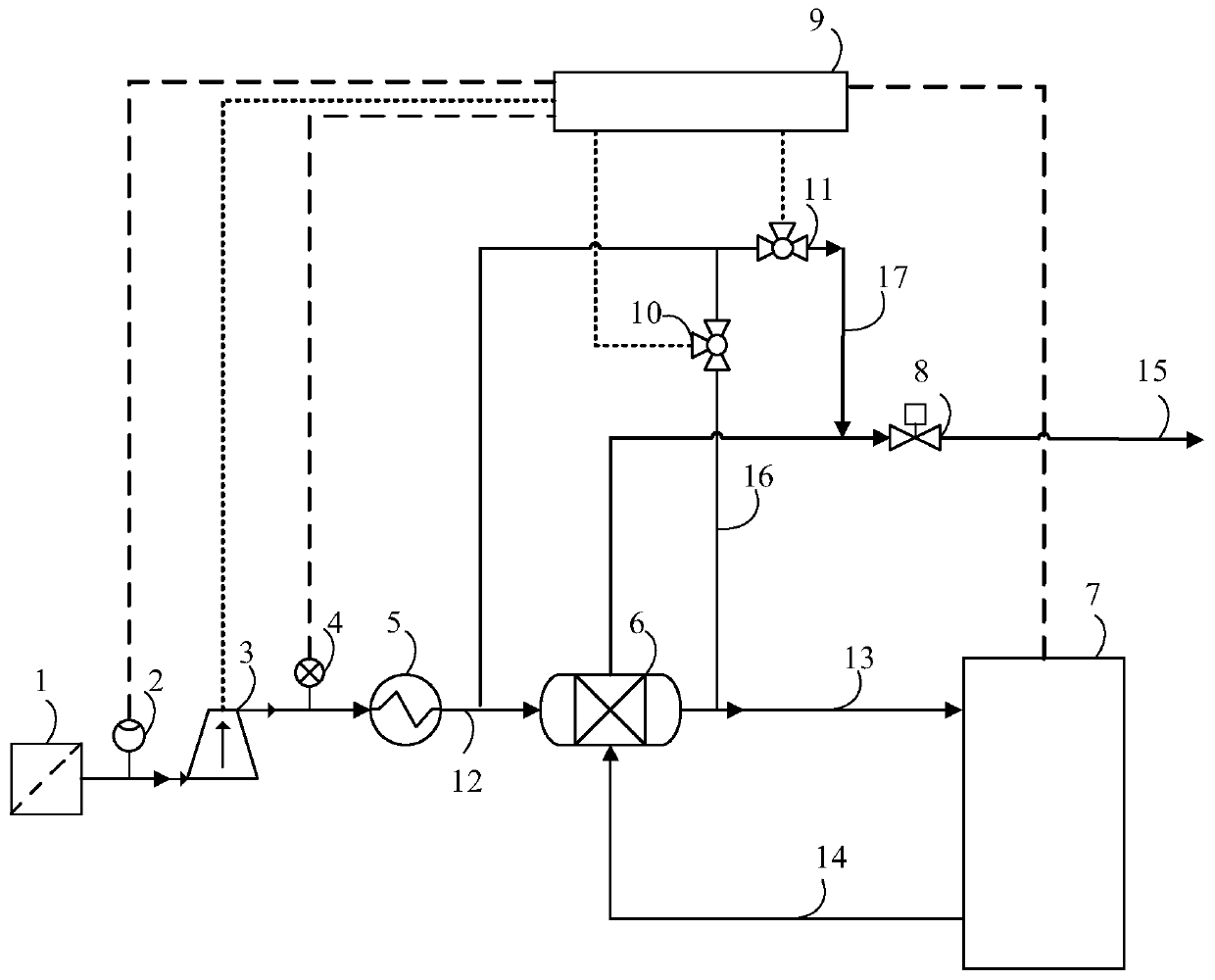

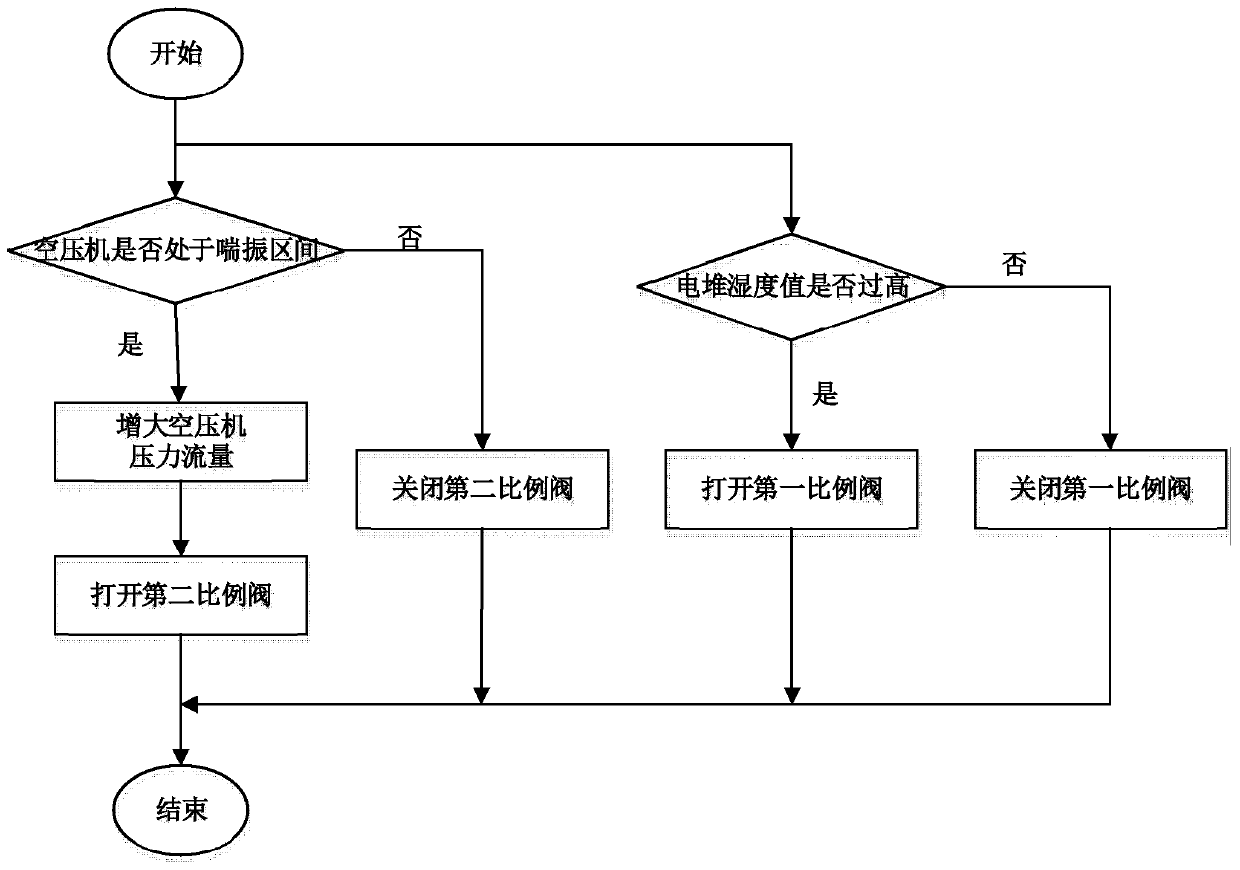

[0061] This embodiment provides a control method of a gas supply device for a fuel cell, the control method adopts figure 2 gas supply shown, and according to image 3 process shown.

[0062] The control unit 18 monitors that the pressure ratio of the air compressor 3 is 2.9, and the flow rate is 150g / s, and at the same time monitors that the humidity value of the electric stack 7 is 100%. The humidity value of stack 7 is higher than the limit humidity value of 95%" judgment result. The control unit 18 controls the air compressor 3 to increase the pressure and flow rate to 160g / s, simultaneously opens the second proportional valve 11 and adjusts the opening to 6%, opens the first proportional valve 10 and adjusts the opening to 80%, so that the part dry The air is passed into the electric stack 7 to reduce the humidity value of the electric stack 7 to 95%, and excess air is discharged from the fuel cell, thereby avoiding the surge problem of the air compressor 3 .

Embodiment 2

[0064] This embodiment provides a control method of a gas supply device for a fuel cell, the control method adopts figure 2 gas supply shown, and according to image 3 process shown.

[0065] The control unit 18 monitors that the pressure ratio of the air compressor 3 is 1.3, the flow rate is 50g / s, and the humidity of the electric stack 7 is 70%. The humidity value of the cell stack 7 is not higher than the limit humidity value of 95%". The control unit 18 controls the air compressor 3 to increase the pressure and flow rate to 70g / s, and at the same time opens the second proportional valve 11 and adjusts the opening to 30%, and closes the first proportional valve 10, thereby discharging excess air from the fuel cell and avoiding air pollution. Surge problem of compressor 3.

Embodiment 3

[0067] This embodiment provides a control method of a gas supply device for a fuel cell, the control method adopts figure 2 gas supply shown, and according to image 3 process shown.

[0068] The control unit 18 monitors that the pressure ratio of the air compressor 3 is 3.0, the flow rate is 200g / s, and the humidity of the stack 7 is 100%. After judgment, it is obtained that "the air compressor 3 is not in the surge zone, But the humidity value of the stack 7 is higher than the limit humidity value of 95%" judgment result. The control unit 18 opens the first proportional valve 10 and adjusts the opening to 100%, and closes the second proportional valve 11, so that part of the dry air is passed into the electric stack 7, and the humidity value of the electric stack 7 is reduced to 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com