Denitrification pretreatment system and method for high-nitrate industrial wastewater and application thereof

A technology for industrial waste water and nitrate, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, filtration treatment, etc., and can solve problems such as low efficiency and increased treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

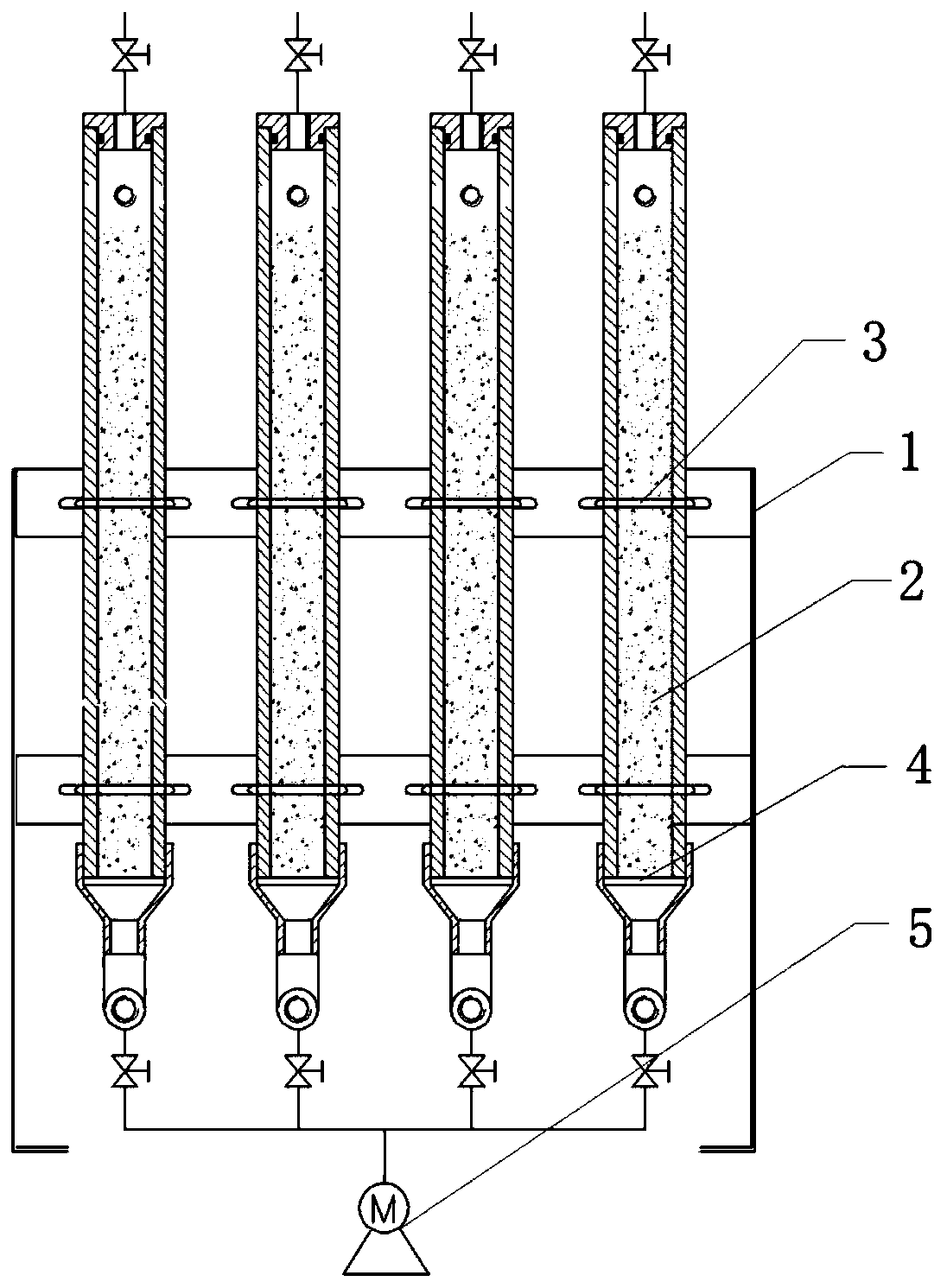

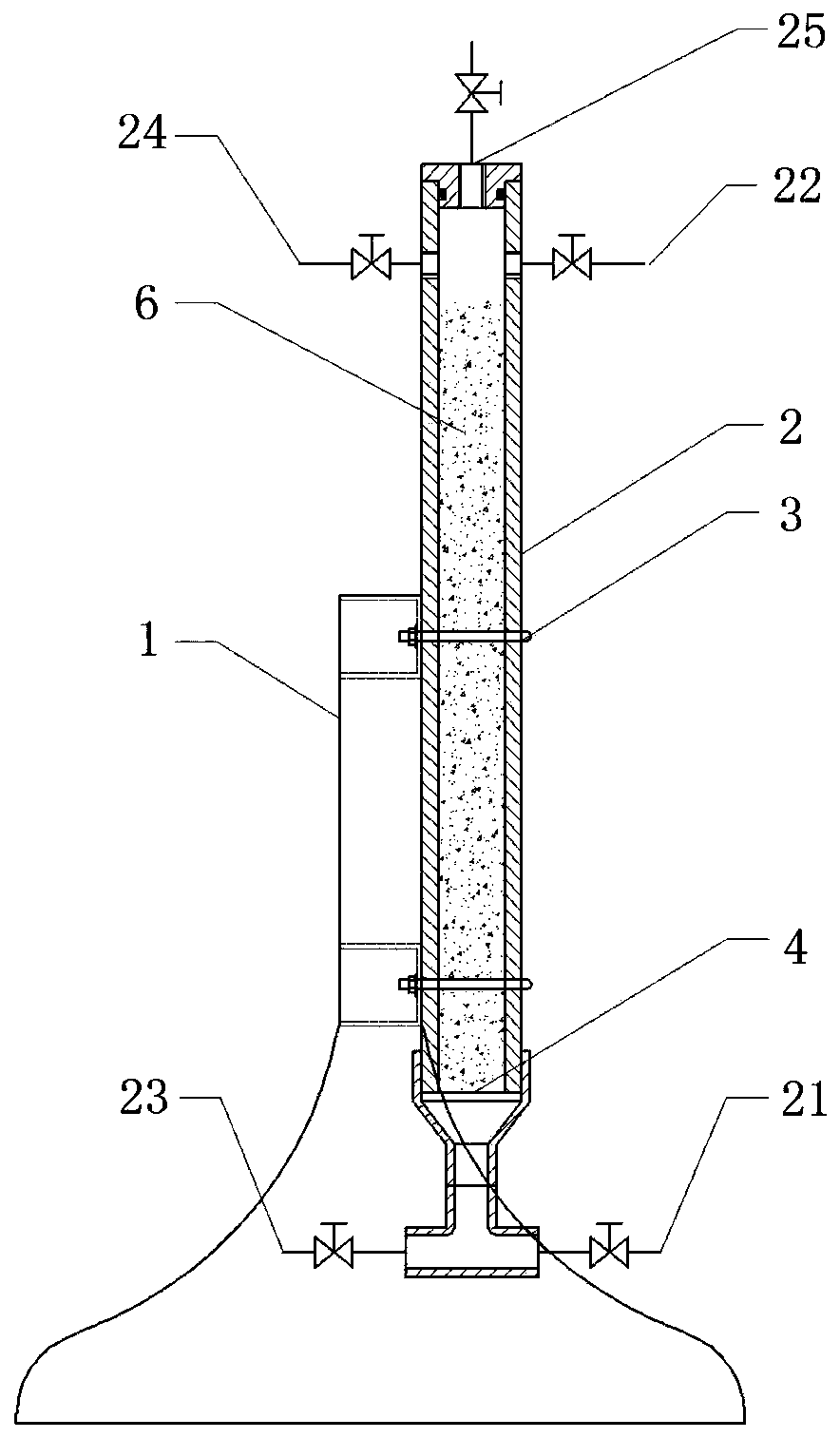

[0050] A high nitrate industrial wastewater denitrification pretreatment system, such as Figure 1-2 As shown, it includes a bracket 1 and several cylinders 2 arranged on the bracket 1 , and the cylinders 2 are vertically connected to the bracket 1 through clamps 3 . It should be pointed out that the number of cylinders 2 in the pretreatment system of the present invention is one or more, all of which should be included in the protection scope of the present invention.

[0051] The cylinder body 2 is provided with a filter plate 4 with an average pore size of 10 mm. The function of the filter plate 4 is to evenly distribute water and then be treated by the biological filter material described below.

[0052] The bottom end of the cylinder body 2 is provided with a sewage water inlet 21, and the upper end of the cylinder body 2 is provided with a sewage water outlet 22, and the sewage water inlet 21 is connected with the sewage to be treated through a sewage water inlet pipe, a...

Embodiment 2

[0065] This embodiment provides a method for pretreating high nitrate industrial wastewater by using the pretreatment system of the above embodiment 1, including:

[0066] Step 1: Membrane hanging and start-up of biofilter:

[0067] Take nitrate-containing wastewater as influent water, take sewage plant return sludge as inoculation sludge, mix nitrate-containing wastewater and inoculation sludge, input through the sewage water inlet 21 of the pretreatment system, carry out film formation, and run continuously until A layer of light brown biofilm is formed on the surface of the biological filter material, indicating that the film is successfully attached;

[0068] Step 2: Pretreatment of high nitrate industrial wastewater

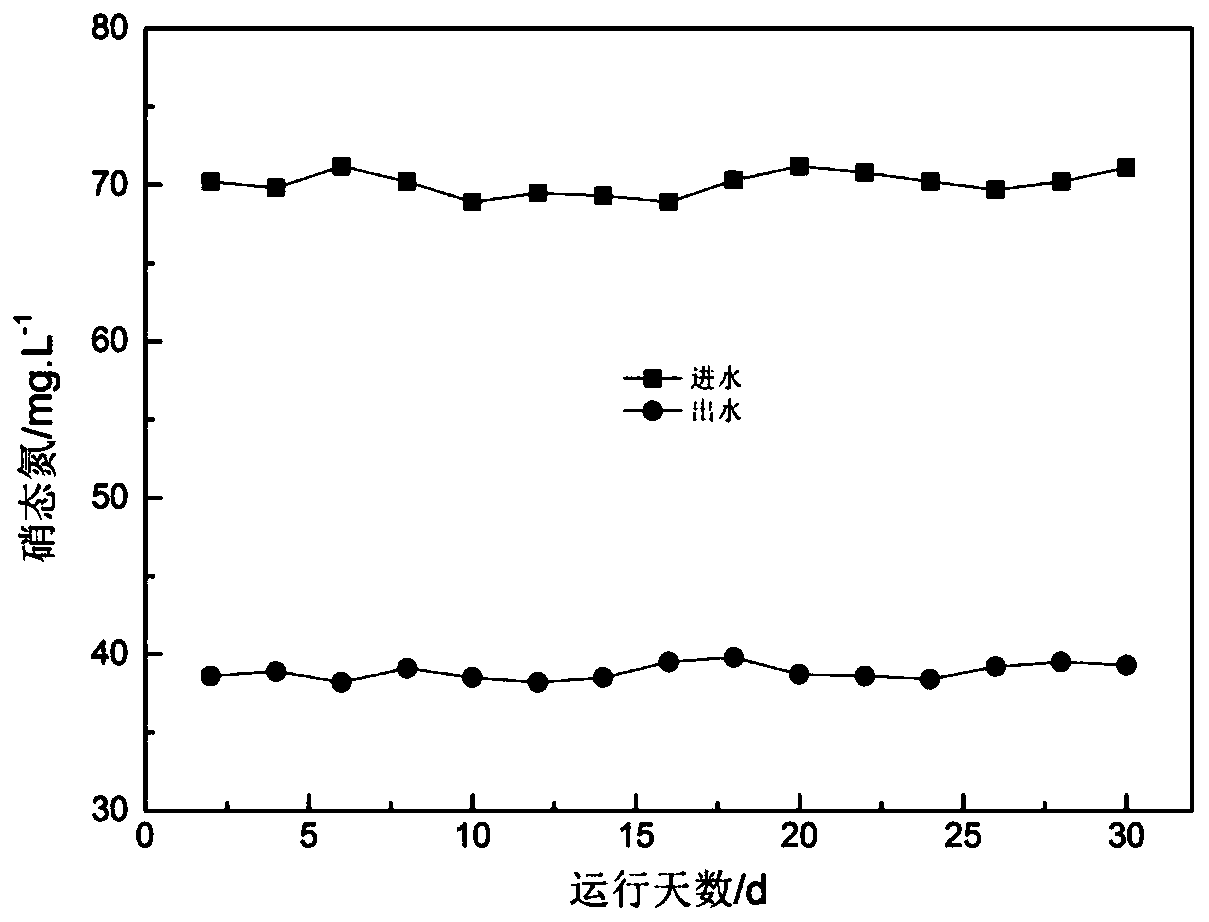

[0069] High nitrate industrial wastewater to be treated passes through the biofilter, in this embodiment, the volume is 1m 3 , the height of the filter material is 1m, the ascending flow rate is 15m / h, the biological filter material is in a slightly expand...

Embodiment 3

[0073] This embodiment provides another method for pretreating high-nitrate industrial wastewater by using the pretreatment system of the above-mentioned embodiment 1, including:

[0074] Step 1: Membrane hanging and start-up of biofilter:

[0075] Take nitrate-containing wastewater as influent water, take sewage plant return sludge as inoculation sludge, mix nitrate-containing wastewater and inoculation sludge, input through the sewage water inlet 21 of the pretreatment system, carry out film formation, and run continuously until A layer of light brown biofilm is formed on the surface of the biological filter material, indicating that the film is successfully attached;

[0076] Step 2: Pretreatment of high nitrate industrial wastewater

[0077] The high nitrate industrial wastewater to be treated passes through the biological filter, the height of the filter material is 35cm, the ascending flow rate is 15m / h, the biological filter material is in a slightly expanded state, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com