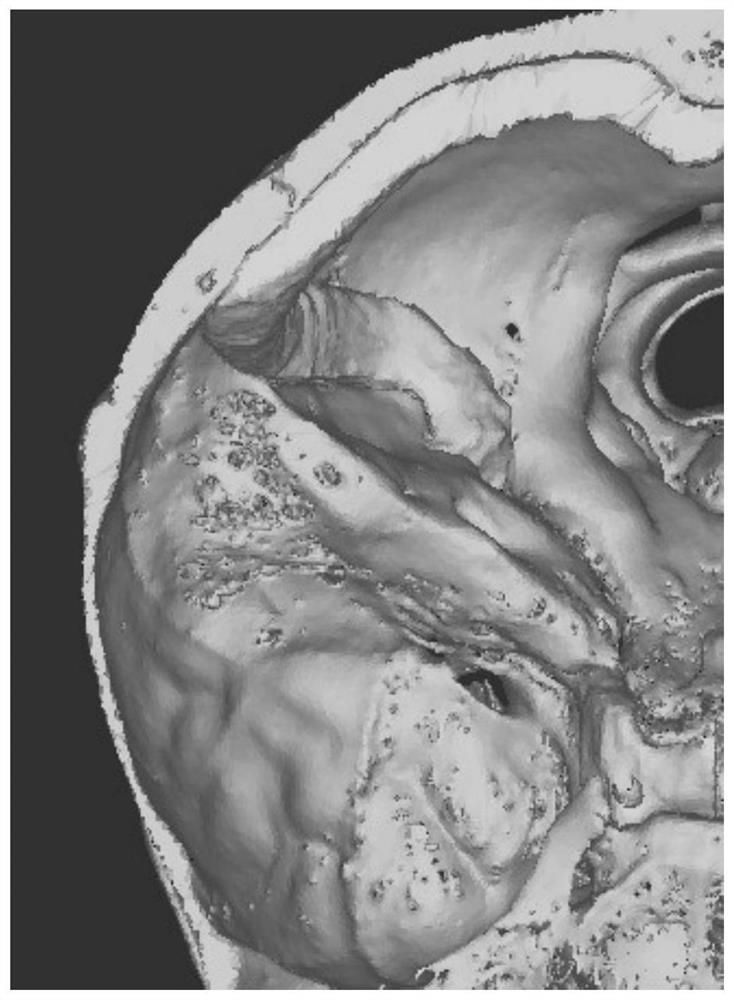

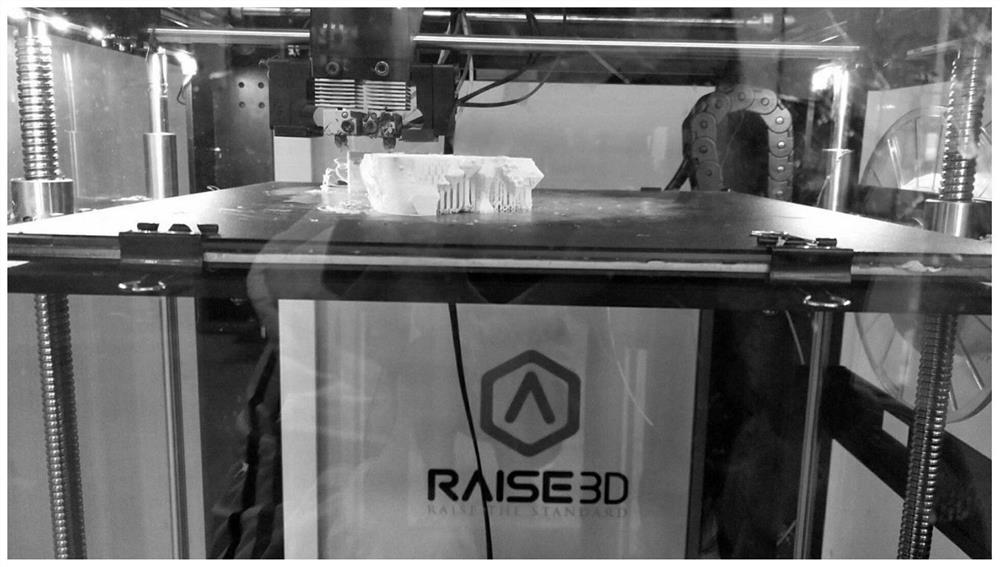

A bone-like 3D printing material and a bone-like 3D printed temporal bone model with bone-like structure and neurovascular structure

A 3D printing, bone-like technology, used in 3D object support structures, manufacturing tools, additive processing, etc., can solve problems such as poor restoration of anatomical microstructures, achieve high printing success rate and stability, weight and hardness Excellent performance, high similarity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Of the Oxygen 3D Printing Material (1) of the present invention

[0035] It is made of a component of the following weight percent: 54.7% by modified polycarbonate, 45% of sulfate and 0.3% of titanium white powder. The modified polycarbonate is modified with acrylate rubber, and the weight ratio of polycarbonate and acrylate rubber is: 34.7: 20.

[0036] Preparation:

[0037] (1) The components are physically mixed and dry after drying according to the weight percentage of the above;

[0038] (2) After drying the prepared masterbatch, a single screw extrusion process is used, and the masterbatch is machined into a circular shape, an average diameter of about 1.75 mm.

Embodiment 2

[0039] Example 2 The human 3D printing material of the present invention (2)

[0040] It is made of a component of the following weight percent: 40% of the modified polycarbonate, 50% of sulfate and 1% of titanium white powder. The modified polycarbonate is modified with acrylate rubber, and the weight ratio of polycarbonate and acrylate rubber is: 29.4: 19.6.

[0041] Preparation:

[0042] (1) The components are physically mixed and dry after drying according to the weight percentage of the above;

[0043] (2) After drying the prepared masterbatch, a single screw extrusion process is used, and the masterbatch is machined into a circular shape, an average diameter of about 1.75 mm.

Embodiment 3

[0044] Example 3 Oxurvic 3D printing material of the present invention (3)

[0045] It is made of the following weight percent components: 60% of the modified polycarbonate, 39% of sulfate and 1% of titanium white powder. Among them, the modified polycarbonate is modified with acrylate rubber, and the weight ratio of polycarbonate and acrylate rubber is: 40:20.

[0046] Preparation:

[0047] (1) The components are physically mixed and dry after drying according to the weight percentage of the above;

[0048] (2) After drying the prepared masterbatch, a single screw extrusion process is used, and the masterbatch is machined into a circular shape, an average diameter of about 1.75 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com