Automatic fish killing machine

An automatic, rack-mounted technology, applied in fish processing, fish workbench, fish cleaning/descaling, etc., can solve the problems of low degree of automation in fish processing, improve reasonable utilization rate, improve mechanization degree, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed descriptions are given in conjunction with specific embodiments and accompanying drawings.

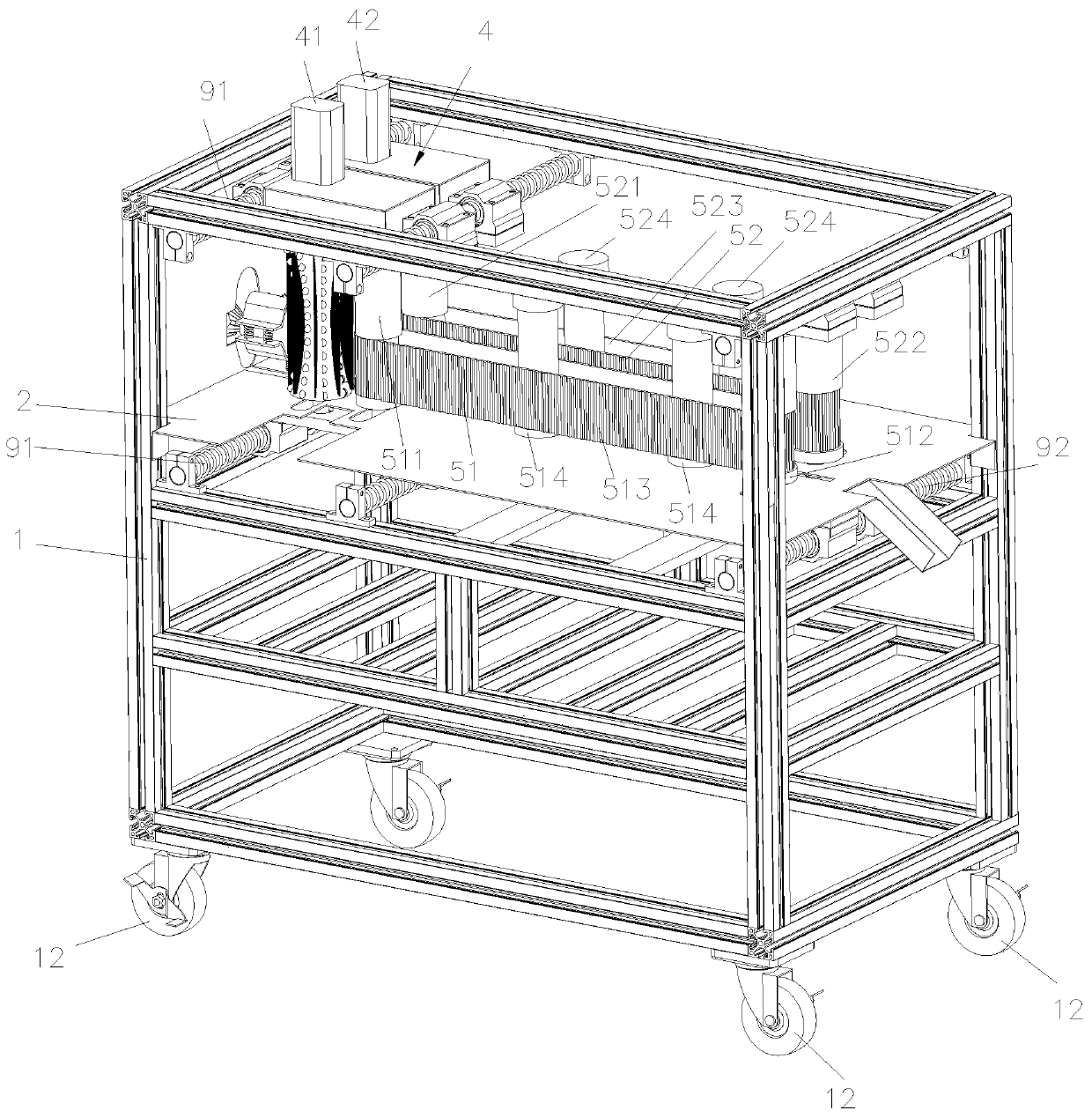

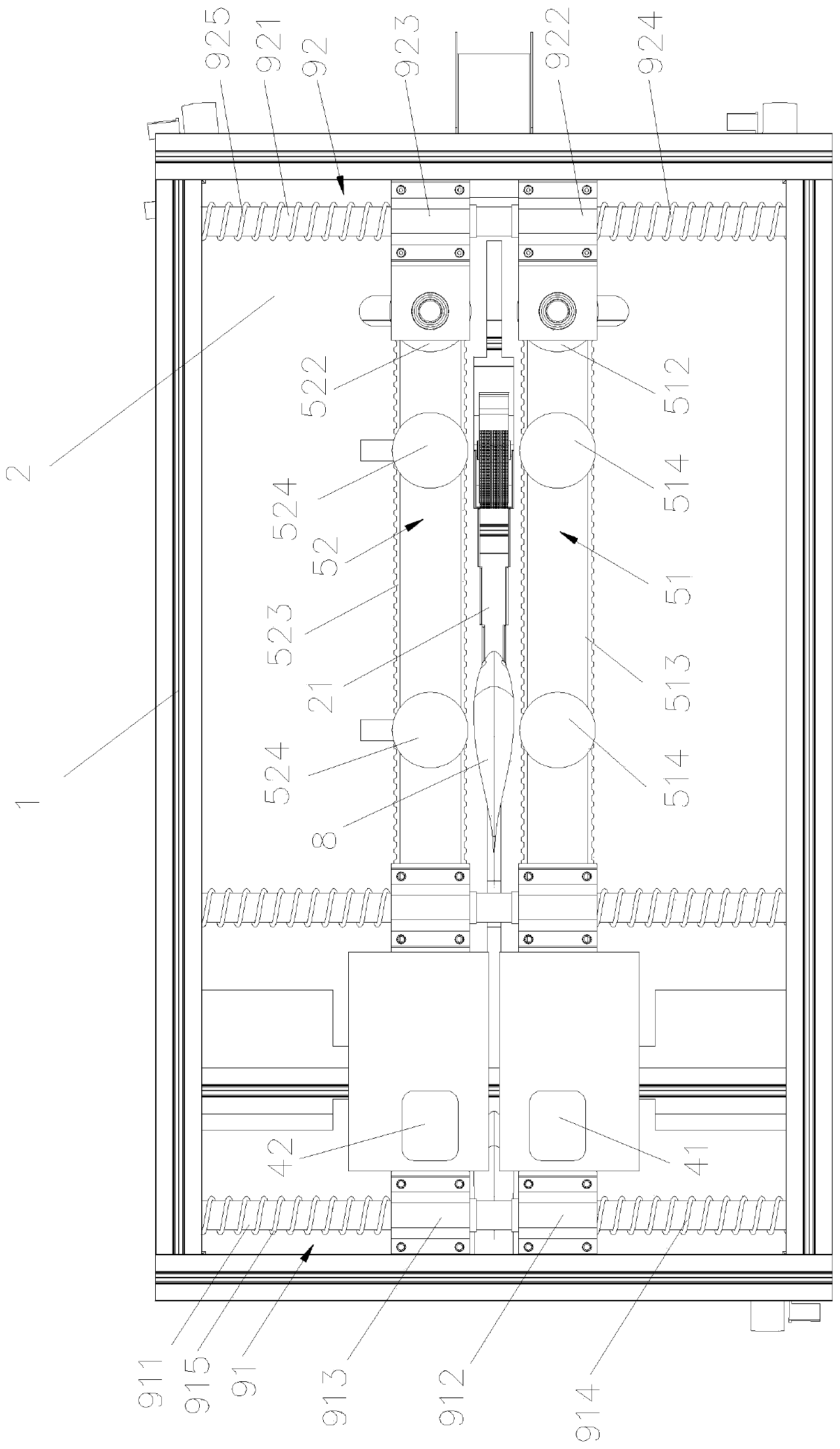

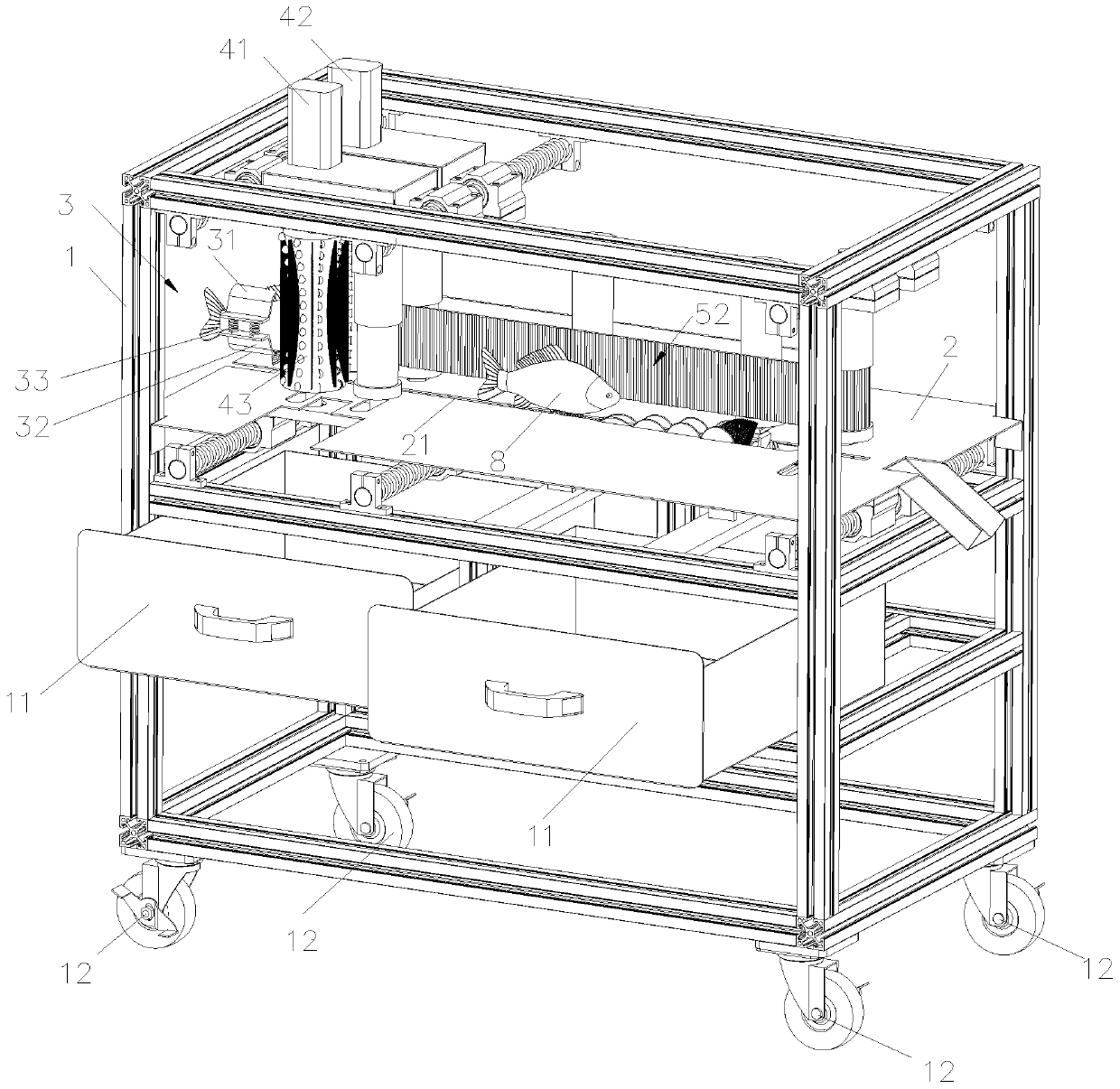

[0078] See Figure 1 to Figure 8 , The present invention provides an automatic fish-killing machine, including a frame 1, a workbench 2, and a clamping device 3, a descaling device 4, a conveying device, a belly cutting device, and a visceral device provided on the workbench. The frame is The frame part of the automatic fish killer provides fixation and support for various components. The fish 8 to be processed enters each work link from above the workbench. The holding device is used to fix the fish to be processed and hold a fish to be processed for processing. The descaling device is used to remove fish scales. The conveying device is used for conveying the fish from which the scales have been removed to the cutting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com