Oil-water separation system for harmless treatment of swill and oil-water separation method thereof

A harmless treatment and oil-water separation technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of slow separation speed, achieve high oil scraping efficiency, fast speed, and improve the quality of scraped oil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

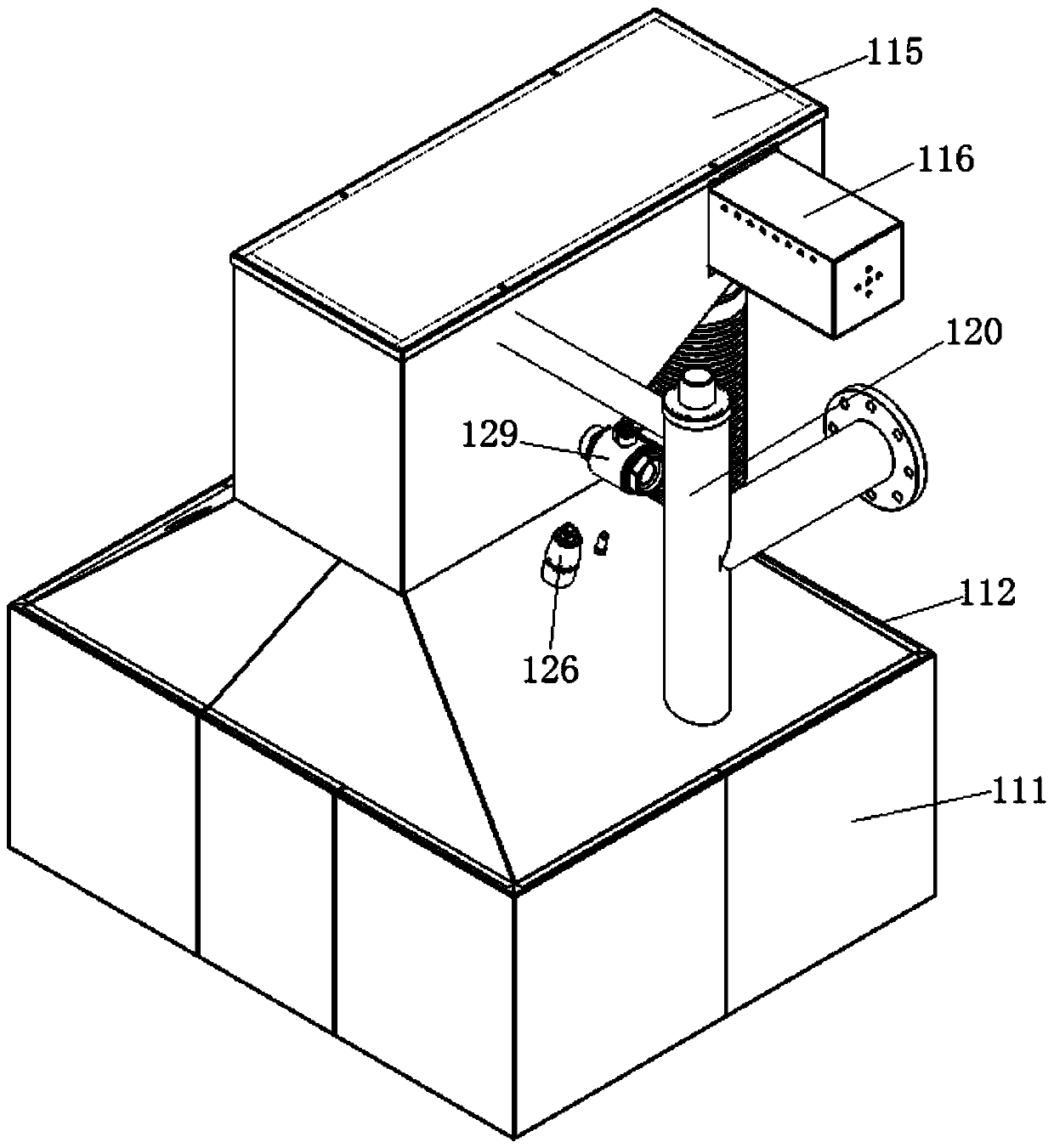

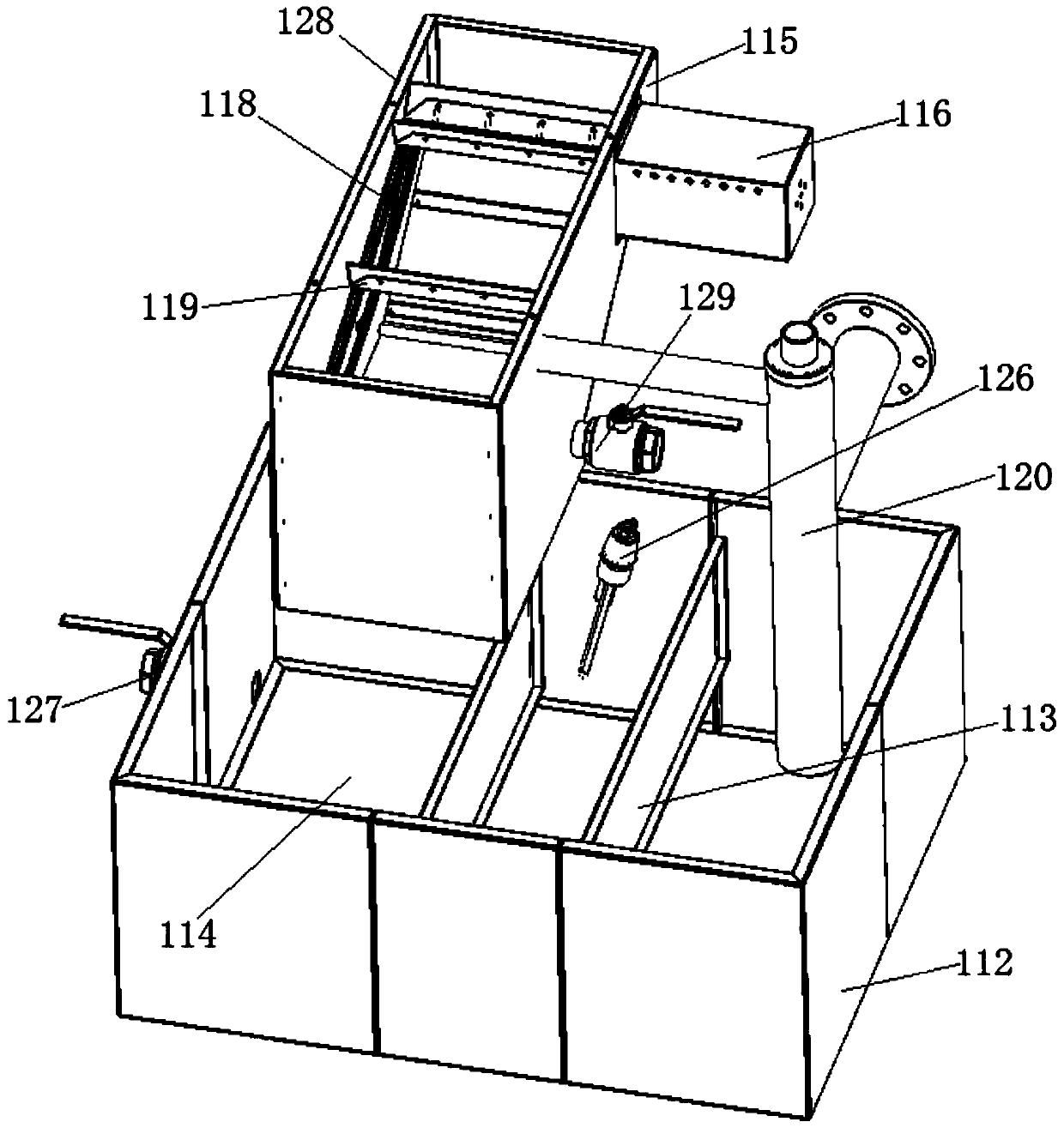

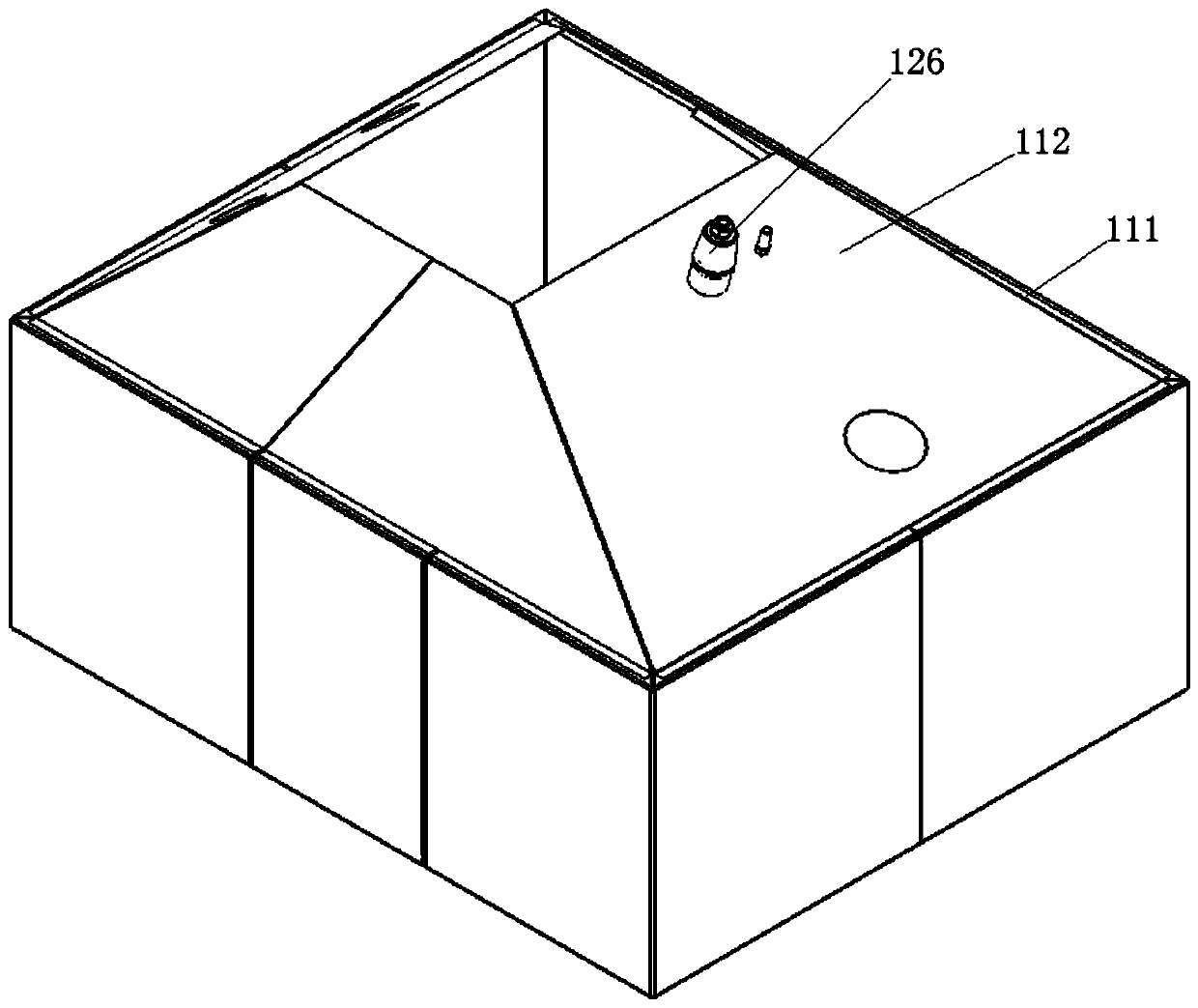

[0074] see Figure 1-6 , This embodiment provides an oil-water separation system for harmless treatment of swill, the system is used to separate the oil-water mixture / liquid that has been squeezed or / and filtered to separate the oil liquid and scum. Wherein, the oil-water separation system includes an oil separation tank 111 , an oil scraping mechanism and a liquid outlet mechanism, and may also include a U-shaped heating pipe 126 .

[0075] The oil separation box 111 includes a box body 112 and a plurality of partition plates 113 , and may also include a ball valve 1 127 . The top of the box body 112 is an inverted funnel-shaped structure, and the top of the box body 112 is opened. A plurality of separating plates 113 are arranged in the first tank 112 and separate a plurality of oil-separating spaces 114 which are connected in sequence. Two adjacent oil separation spaces 114 communicate through the upper space and the lower space of a partition plate 113 . An oil isolatio...

Embodiment 2

[0084] see Figure 7 as well as Figure 8 , this embodiment provides an oil-water separation system for harmless treatment of swill, which adds a detection mechanism, an oil-water separation controller, a feed pipe 122 and a feed valve 123 on the basis of Embodiment 1.

[0085] The detection mechanism is used to detect the parameters of the liquid in the scraper tank 115 and includes a liquid level sensor 121 . The liquid level sensor 121 is installed in the scraper tank 115 and is used to detect the liquid level of the liquid in the scraper tank 115 . The liquid level sensor 121 can adopt the existing ranging sensor, which can emit electromagnetic waves to the liquid surface and receive the electromagnetic waves reflected by the liquid surface, so as to record the time spent in the whole process, so that the distance of one-way transmission can be calculated, and Further, the height of the liquid surface can be calculated.

[0086] There is at least one feed pipe 122, whic...

Embodiment 3

[0090] see Figure 9-17 , this embodiment provides an oil-water separation system for harmless treatment of swill, which is used together with an extrusion system. The extruding system includes an extruding frame 51 , an extruding shell 52 , a screw rod 54 , an extruding motor 55 and a locking mechanism, and may also include an outlet pipe 76 . The extruding frame 51 is composed of a plurality of square tubes spliced together, and the splicing method can be welding, clamping, screwing, etc., and of course it can also be integrally formed. The bottom end of the extruding frame 51 can be provided with structures such as pulleys, so that the extruding frame 51 can move on the ground. At the same time, the bottom of the extruding frame 51 can also be provided with a limit structure, which can limit the movement of the extruding frame 51 on the ground and ensure that the extruding frame 51 is stably placed in the required fixed position. Of course, the surface of the extruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com