Preparation method of polymer anion exchange membrane

An anion exchange membrane and polymer technology, which is applied in the field of preparation of functional polymer materials, can solve the problems of increasing technical complexity and cost, affecting the phase separation structure, etc., and achieves a simple heat treatment crosslinking process, low cost, and improved physical stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

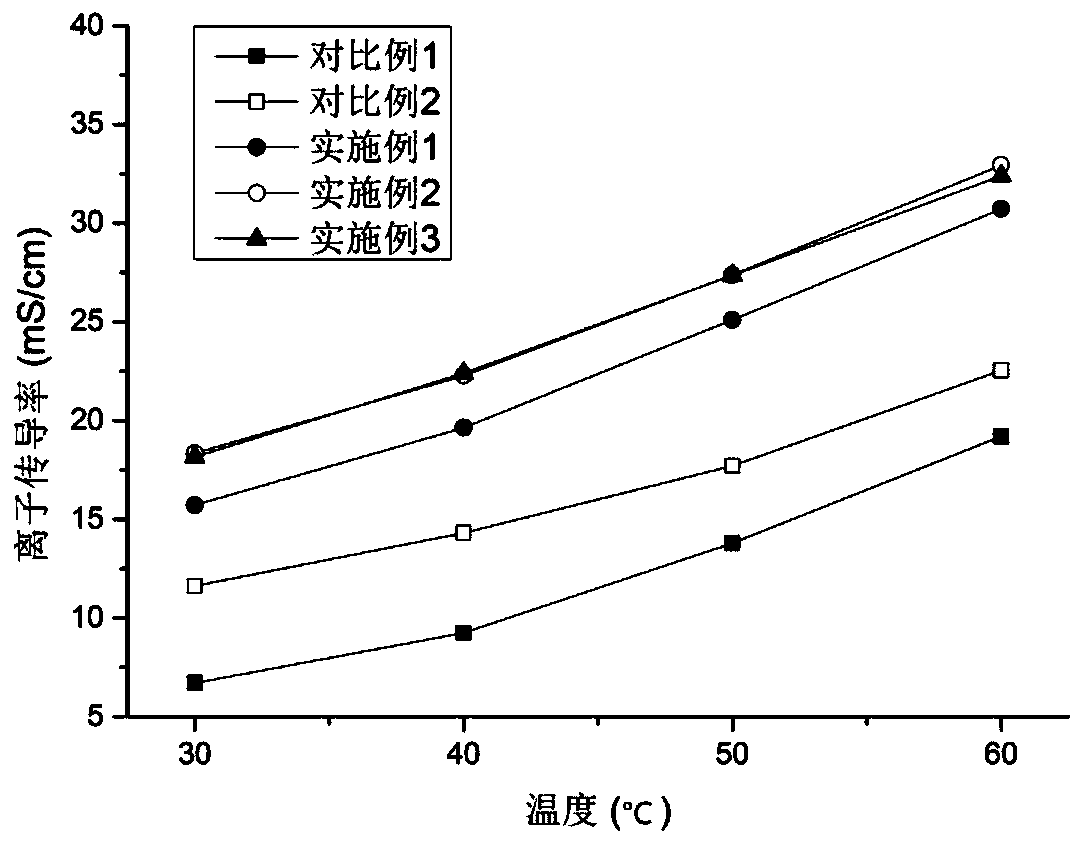

Embodiment 1

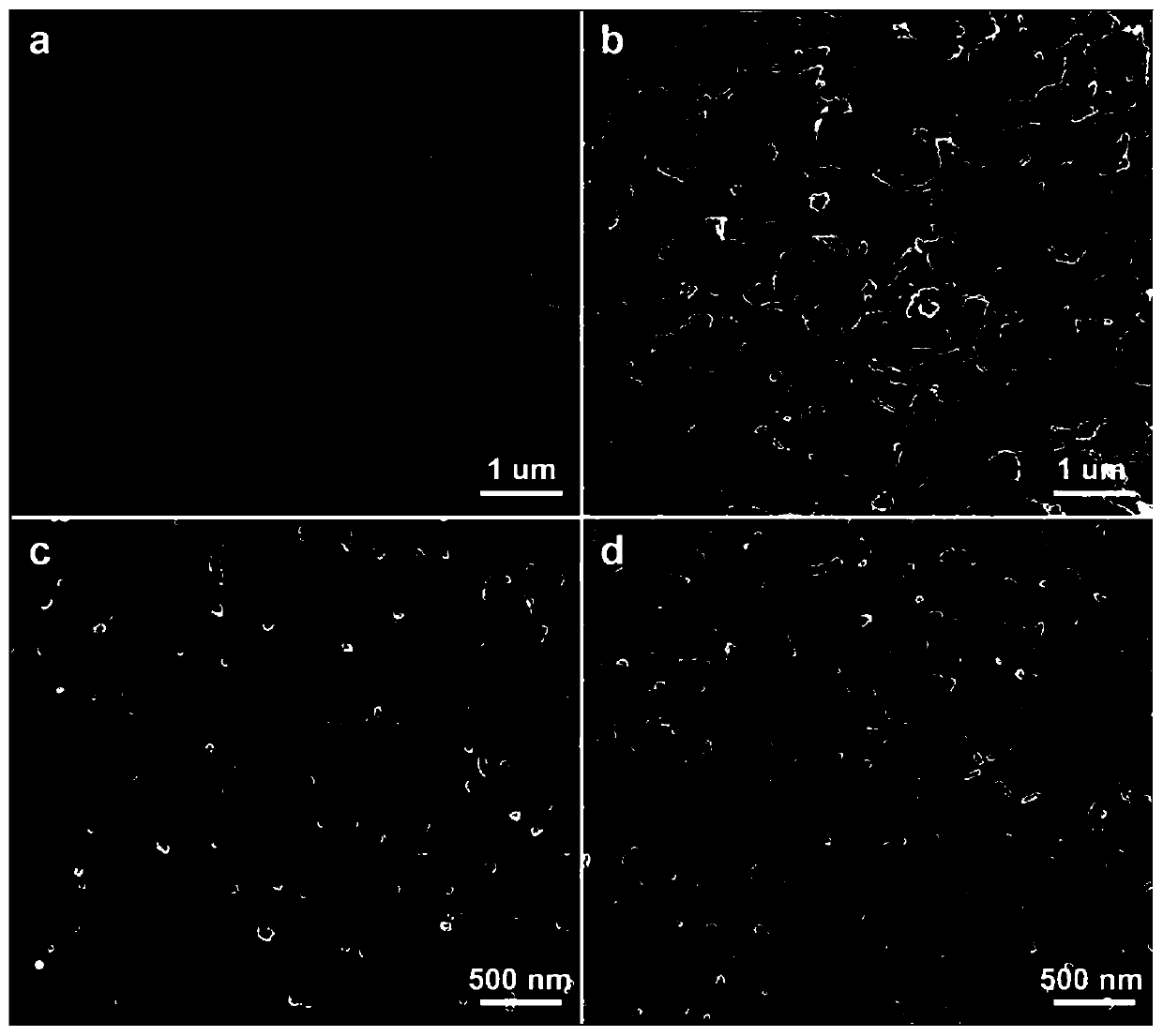

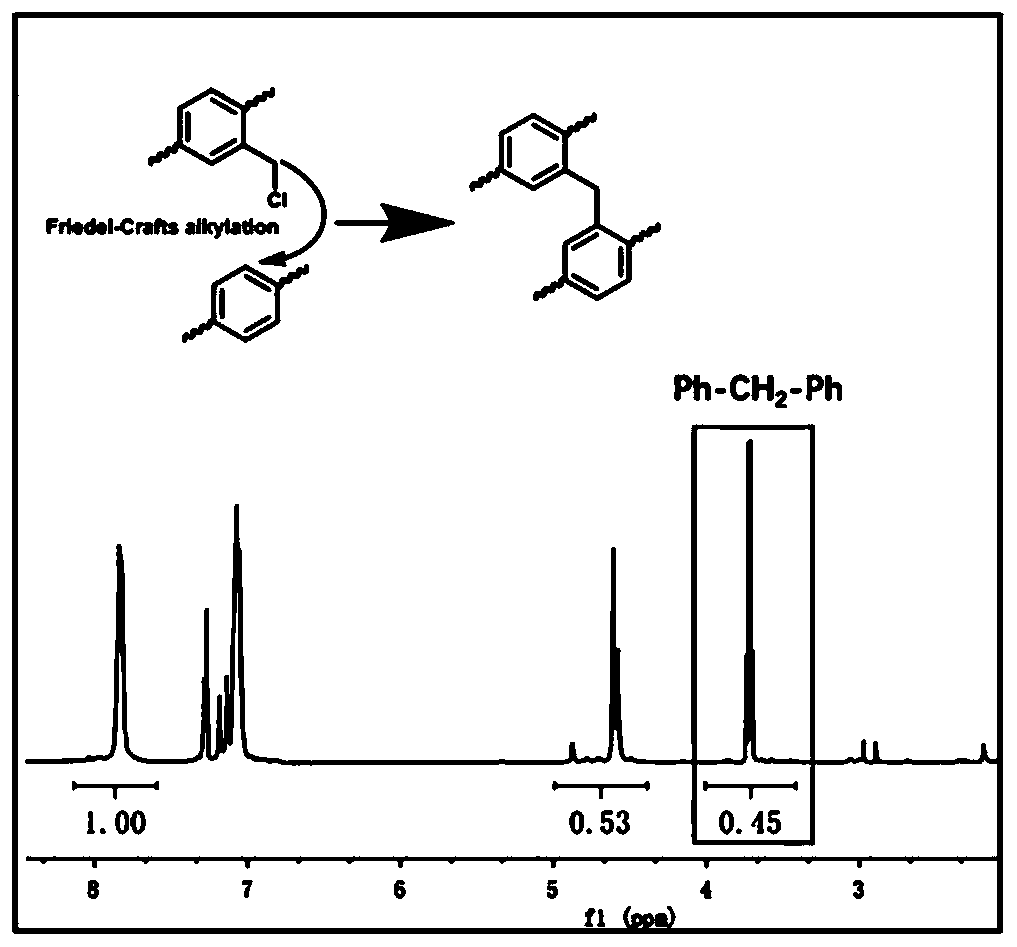

[0037] (1) Dissolve 4g of polyether ether ketone in 240mL of concentrated sulfuric acid at a temperature of -10°C; then add 20ml of chloromethyl octyl ether, raise the temperature by 10°C, and react for 50 minutes to obtain poly Ether ether ketone; reacted for 18h to obtain polyether ether ketone with a high degree of chloromethylation; the polymer was precipitated in ethanol;

[0038] (2) 25 mg of high chloromethylated polyether ether ketone prepared in step (1) was dissolved in NMP, and 225 mg of high chloromethylated polyether ether ketone prepared in step (1) was dissolved in NMP, the obtained The mass concentrations of the low-chloromethylated polyetheretherketone solution and the high-chloromethylated polyetheretherketone solution are both 5wt%;

[0039] 30mg of 1-methylimidazole was added to the high chloromethylated polyetheretherketone solution to react at room temperature for 2 hours, then added to the low chloromethylated polyetheretherketone solution, and reacted a...

Embodiment 2

[0044] (1) Dissolve 4g of polyether ether ketone in 240mL of concentrated sulfuric acid at a temperature of -10°C; then add 20ml of chloromethyl octyl ether, raise the temperature by 10°C, and react for 50 minutes to obtain poly Ether ether ketone; reacted for 18h to obtain polyether ether ketone with a high degree of chloromethylation; the polymer was precipitated in water;

[0045] (2) Dissolving 50 mg of high chloromethylated polyether ether ketone prepared in step (1) in NMP, and dissolving 200 mg of high chloromethylated polyether ether ketone prepared in step (1) in NMP, the resulting The mass concentrations of the low-chloromethylated polyetheretherketone solution and the high-chloromethylated polyetheretherketone solution are both 4wt%;

[0046] 27mg of 1-methylimidazole was added to the high chloromethylated polyetheretherketone solution to react at room temperature for 3 hours, then added the low chloromethylated polyether ether ketone solution, and reacted at 50°C f...

Embodiment 3

[0051] (1) Dissolve 4g of polyetheretherketone in 240mL of concentrated sulfuric acid at -10°C. Then add 20ml of chloromethyl octyl ether, raise the temperature by 10°C, and react for 50 minutes to obtain polyether ether ketone with low degree of chloromethylation; react for 18 hours to obtain polyether ether ketone with high degree of chloromethylation. The polymer precipitates out in water;

[0052] (2) Dissolving 75 mg of high chloromethylated polyether ether ketone prepared in step (1) in NMP, and dissolving 175 mg of high chloromethylated polyether ether ketone prepared in step (1) in NMP, the resulting The mass concentrations of the low-chloromethylated polyetheretherketone solution and the high-chloromethylated polyetheretherketone solution are both 7wt%;

[0053] 35 mg of 1-methylimidazole was added to the high chloromethylated polyetheretherketone solution for room temperature reaction for 1 hour, then the low chloromethylated polyetheretherketone solution was added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com