Robot virtual reality synchronization system and synchronization method

A technology of virtual reality and synchronous system, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve good interactivity, improve automation level and safety, and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

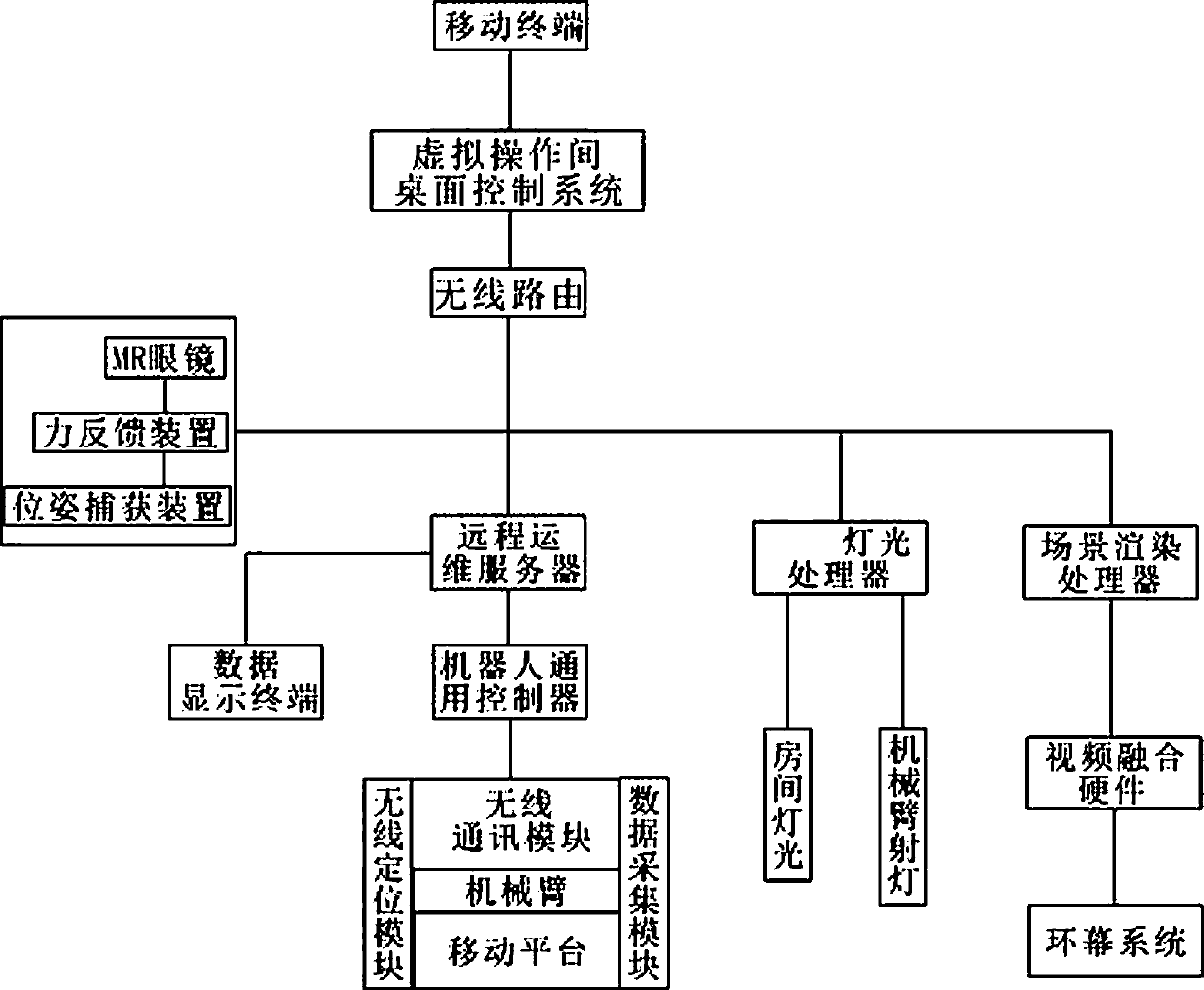

[0031] As a most basic embodiment of the system of the present invention, such as figure 1 A robot virtual reality synchronization system disclosed in this embodiment includes an MR glasses system, a virtual operation room and a robot with a robot control system; the virtual operation room includes a desktop control system electrically connected to the MR glasses system through a router , the desktop control system is also connected to the robot control system through the network; that is, the MR glasses system is connected to the robot control through the virtual operation room. According to actual use, a single set of MR glasses systems can be located in different places and a number of robot.

[0032] The MR glasses system includes MR glasses for wearing, a force feedback device and a pose capture device; both the force feedback device and the pose capture device are electrically connected to the MR glasses; the MR glasses are connected to the desktop control system data S...

Embodiment 2

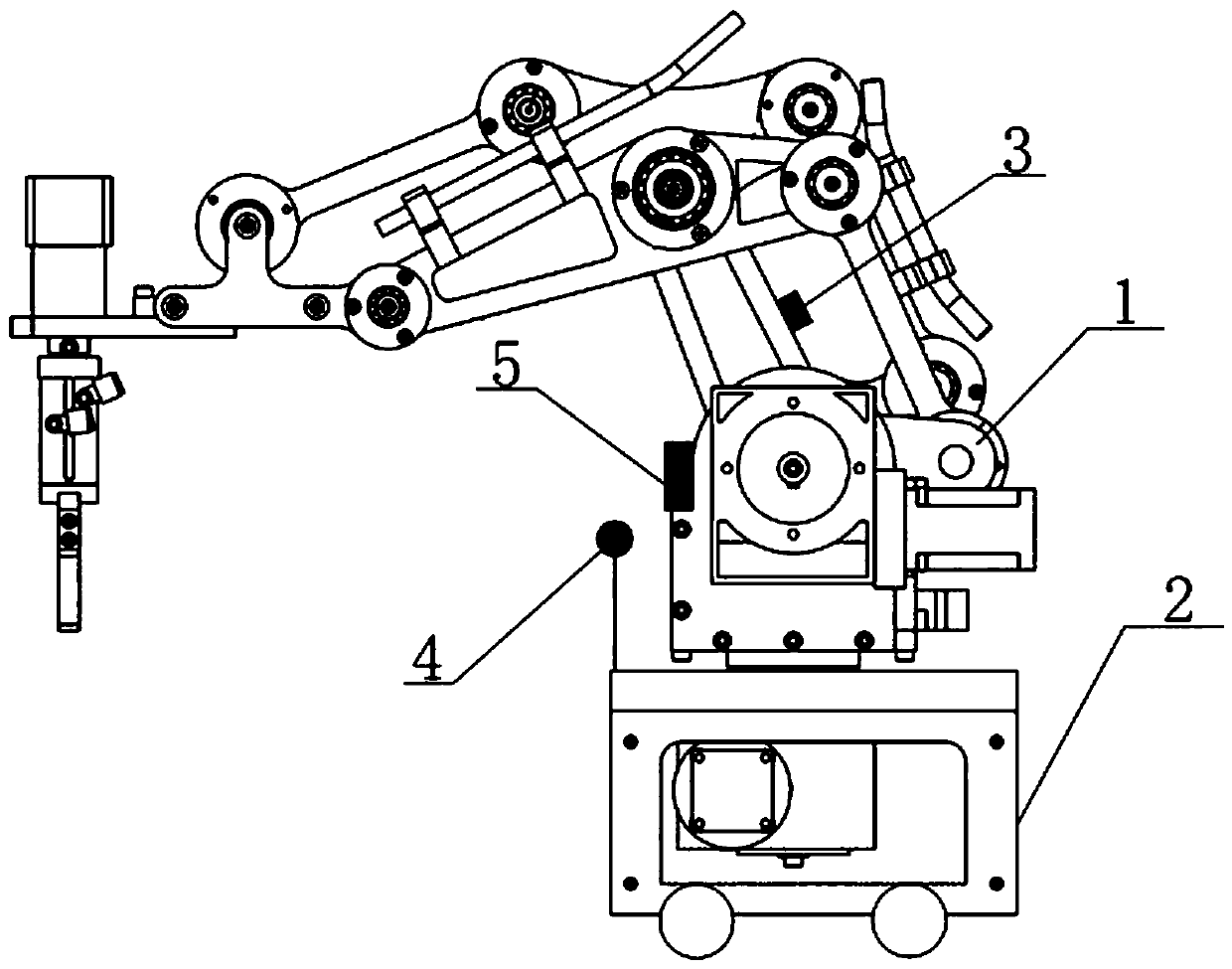

[0035] As a preferred implementation of the system of the present invention, on the basis of Example 1, further, the robot includes a mechanical arm 1 arranged on a mobile platform 2 driven by a drive motor and a drive shaft, and the mobile platform 2 can realize The fast arrival of the robot.

[0036] Preferably, as figure 2 , the data acquisition module is arranged on the mechanical arm 1 of the robot, and the data acquisition module includes a six-axis force sensor 3 for collecting the output power of the drive shaft of the mechanical arm 1, and a three-dimensional image for completing all feature points of the equipment in the field of view A binocular camera 4 for measurement and a depth camera 5 for three-dimensional measurement and scanning of the device by using changes in incident light signals and reflected light signals. The six-axis force sensor 3 is installed on the drive shaft of the robot arm 1, the binocular camera 4 is installed on the mobile platform 2 of t...

Embodiment 3

[0039] As a most basic implementation of the method of the present invention, this embodiment discloses a method for synchronizing robot virtual reality, including the following steps:

[0040] Step 1, verify identity and log in through the desktop control system in the virtual operation room;

[0041] Step 2, use the MR glasses system to select the robot to be synchronously controlled in the system through the desktop control system and connect with its robot control system to obtain the robot's field of view, and use the force feedback device and pose capture device of the MR glasses system to communicate with the robot's The action unit is connected synchronously with the joint data of the robotic arm 1;

[0042] Step 3: Control the mobile platform 2 of the robot to move to the target position through the MR glasses system, measure the current environment and fault point working condition images through the depth camera 5 of the robot, construct and upload a 3D environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com