Manufacturing method of mildew-proof height-adjustable round bamboo walking stick

An adjustable, round bamboo technology, applied in the direction of manufacturing tools, mechanical equipment, wood processing details, etc., can solve the problem that height is not necessarily suitable, and achieve the effects of low production cost, short molding cycle, and good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

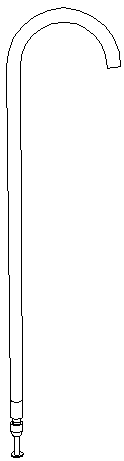

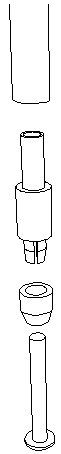

[0032] A mildew-resistant round bamboo walking stick with adjustable height is as follows:

[0033] (1) High-temperature saturated steam treatment of small-diameter round bamboo. The fresh 25mm-diameter bamboo stalks are cut into 93mm lengths according to the requirements, and the inner nodes are cut to the side. Put the round bamboo with a small diameter on the rack of the trolley, push the trolley into the pressure tank and close the tank door, then inject saturated steam into the tank, and process it in a saturated steam pressure tank with a temperature of 183°C for 10 minutes. Then pass the steam in the tank to other pressure tanks that need to be treated to release the pressure.

[0034] In the step (2), the end of the round bamboo is bent into a handle, and the handle end of the bamboo tube just out of the tank is heated to shape the handle.

[0035] In the step (3) drying treatment, put the bent and formed small-diameter round bamboo into a drying kiln, and dry it at a...

Embodiment 2

[0040] A mildew-resistant round bamboo walking stick with adjustable height is as follows:

[0041] (1) High-temperature saturated steam treatment of small-diameter round bamboos. Fresh Qiongzhu bamboo poles with a diameter of 25mm are cut into 85mm lengths according to requirements, and the inner nodes are cut to the side. Put the round bamboo with a small diameter on the rack of the trolley, push the trolley into the pressure tank and close the tank door, then inject saturated steam into the tank, and treat it in a saturated steam pressure tank with a temperature of 160°C for 60 minutes. Then pass the steam in the tank to other pressure tanks that need to be treated to release the pressure.

[0042] In the step (2), the end of the round bamboo is bent into a handle, and the handle end of the bamboo tube just out of the tank is heated to shape the handle.

[0043] In the step (3) drying treatment, air-dry the bent round bamboo with a small diameter until the moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com