Energy-saving and environment-friendly corrugated paperboard production technology

A technology for corrugated cardboard and production process, applied in the field of corrugated cardboard manufacturing, can solve the problems of increased resources, energy consumption, decreased strength of cardboard, increased material usage, etc., and achieves the effects of energy conservation and environmental protection in the production process, improved mechanical strength, and increased usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An energy-saving and environment-friendly corrugated cardboard production process, comprising the following steps:

[0029] S1. Paint configuration, the specific steps are as follows:

[0030] S11. In parts by weight, add 100KG of deionized water to the paint preparation barrel, start the mixer to stir at a speed of 600rpm / min, and slowly add 0.6KG of cationic starch for 25 minutes to make the cationic starch in the deionized water Fully disperse to obtain cationic starch dispersion;

[0031] S12. Continue stirring at a speed of 600rpm / min in the dispersion obtained in step S11, and add 0.015KG of nanocrystalline cellulose suspension, and stir for 20 minutes to obtain a mixed dispersion of cationic starch and nanocrystalline cellulose;

[0032] S13. Ultrasonic treatment of the dispersion liquid obtained in step S12 for 30 minutes, with an ultrasonic treatment power of 1000w;

[0033] S14. Heating, stirring, and gelatinizing the ultrasonically treated dispersion in ste...

Embodiment 2

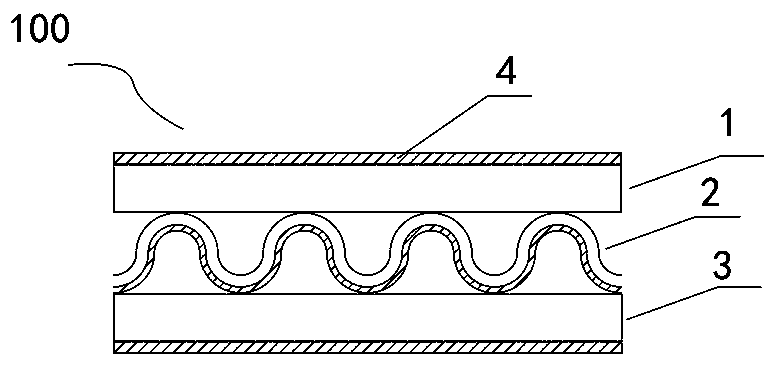

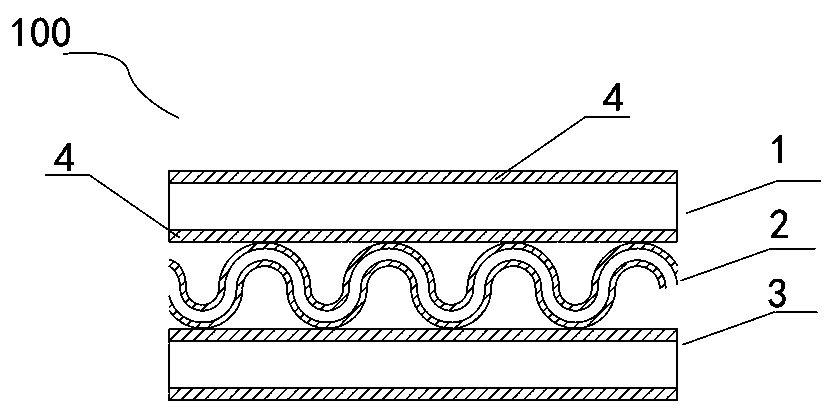

[0043] like figure 2 As shown, this embodiment adopts the coating formula and production process of Embodiment 1, the difference is: in this embodiment, the coating of the above-mentioned configuration is sprayed on both sides of the surface paper 1, the core paper 2 and the inner paper 3 by the spraying device. The front and back surfaces, the side where the top paper 1 and the inner paper 3 will be combined with the core paper 2 is defined as the back side, and the amount of spraying on the front side is 20g / m 2 , the amount of spraying on the reverse side is 15g / m 2 , so as to form a reinforced coating 4 on the front and back of the base paper, so that the tensile strength of the base paper with the reinforced coating 4 will be improved by nearly 15Nm / g than that of the base paper not coated with the reinforced coating 4, and then pass The adhesive glues the core paper 2 between the face paper 1 and the back paper 3, thereby forming the cardboard 100 formed by the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com