Axle box built-in side beam based on new primary spring seat

A built-in, spring seat technology, applied in axle box installation, railway car body parts, bogies, etc., can solve the problems of increasing the bogie structure size and turning radius, the influence of layout space and structural form, and poor structural strength. Achieve the effect of reducing contour volume and turning radius, ensuring balance stability and comfort, reducing structural size and turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

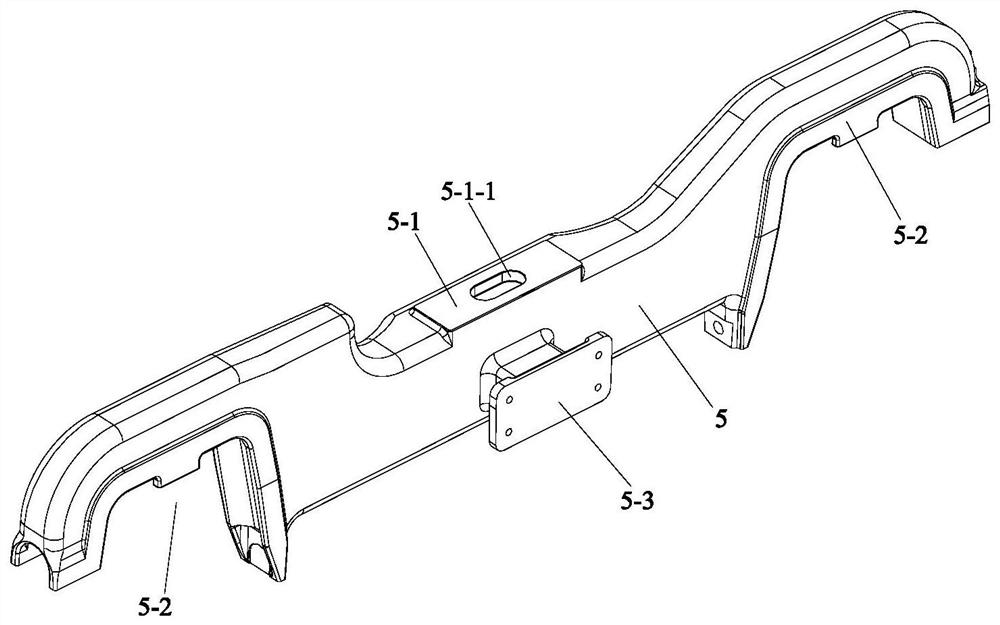

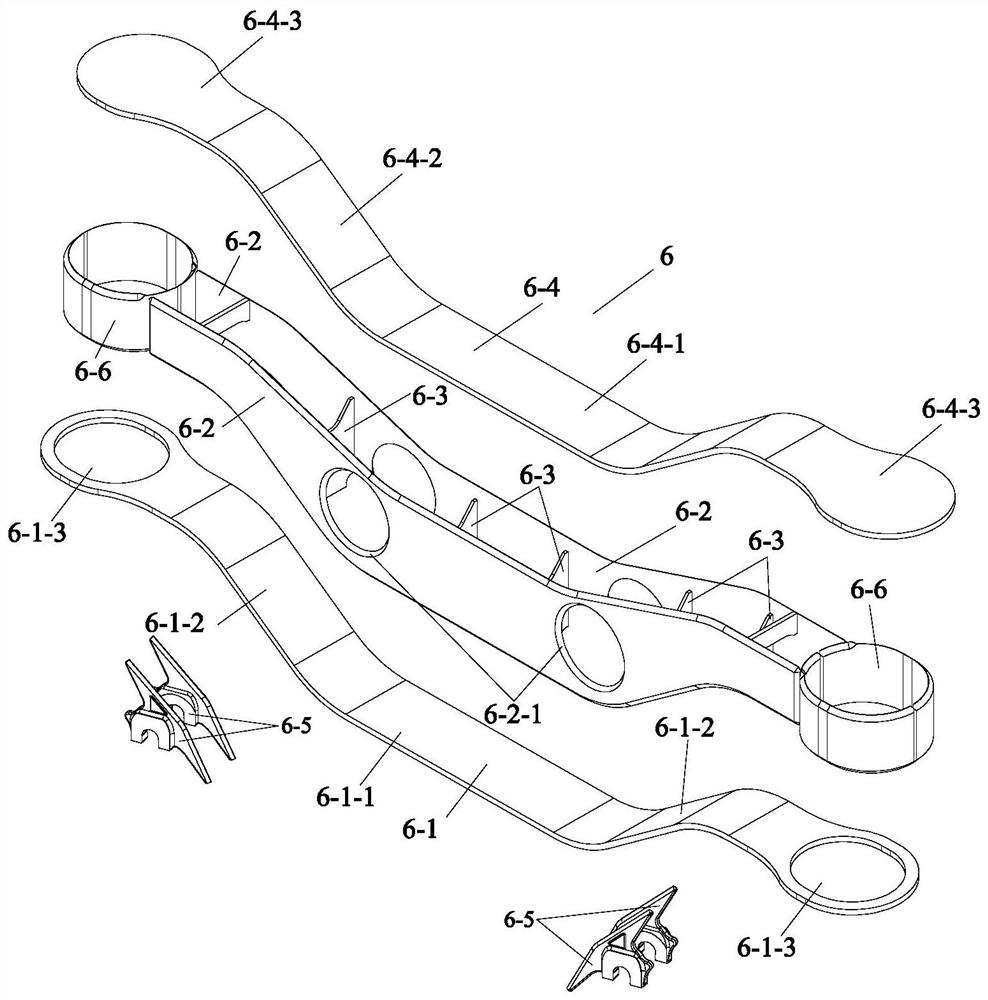

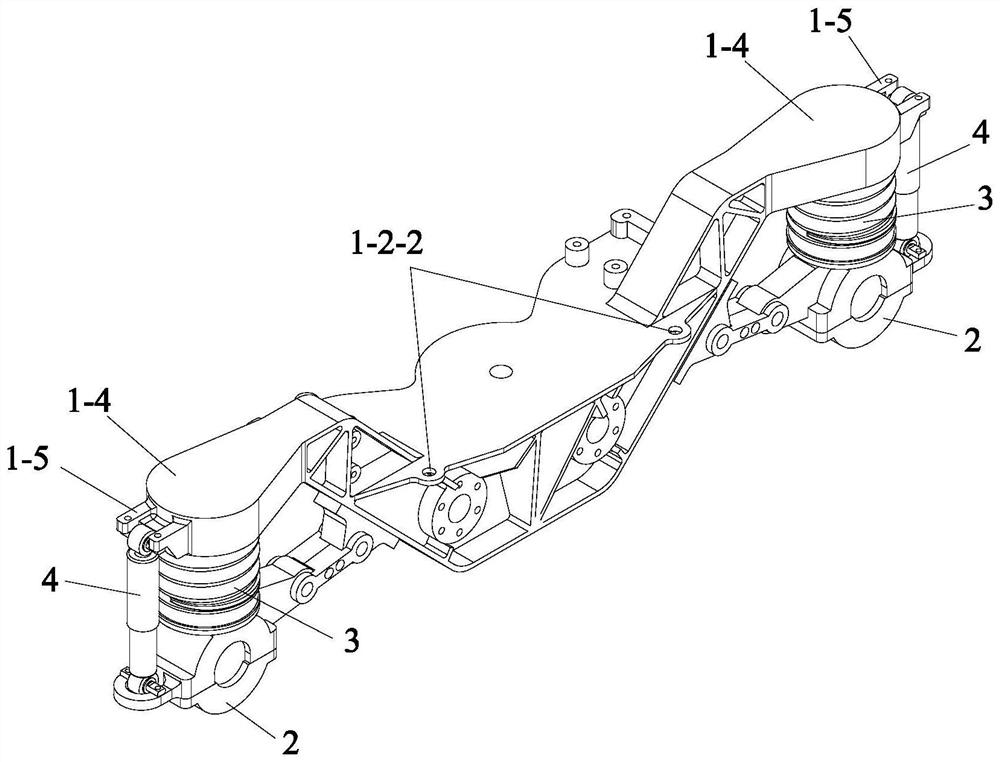

[0038] Such as Figure 3 to Figure 10 As shown, the axle box built-in side beam based on the novel primary spring seat of the present invention includes two primary steel springs 3, two primary vertical shock absorbers 4, forging side beam device 1 and two built-in wheelsets. Type one suspension axle box device 2, forged side beam device 1 includes forged side beam lower cover plate 1-1, forged side beam upper cover plate 1-2, central single vertical plate 1-3, two forged caps Barrel 1-4, two forging vertical shock absorber hangers 1-5, two forging brake hangers 1-6, two oblique transition connection seats 1-7, two forging beam tube connection seats 1-8 Milling residual ribs 1-9 with multiple forgings.

[0039] The lower cover plate 1-1 of the forged side beam is an inverted isosceles trapezoidal plate frame; It becomes the lower bottom edge of its inverte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com