A production device and production method of ultra-fine glass fiber cotton integrated with centrifugal blowing and beating

A technology of ultra-fine glass fiber and glass fiber cotton, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high thermal conductivity of heat insulation board, uneven fiber loosening, uneven loosening of raw cotton, etc. Dispersion, the effect of saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

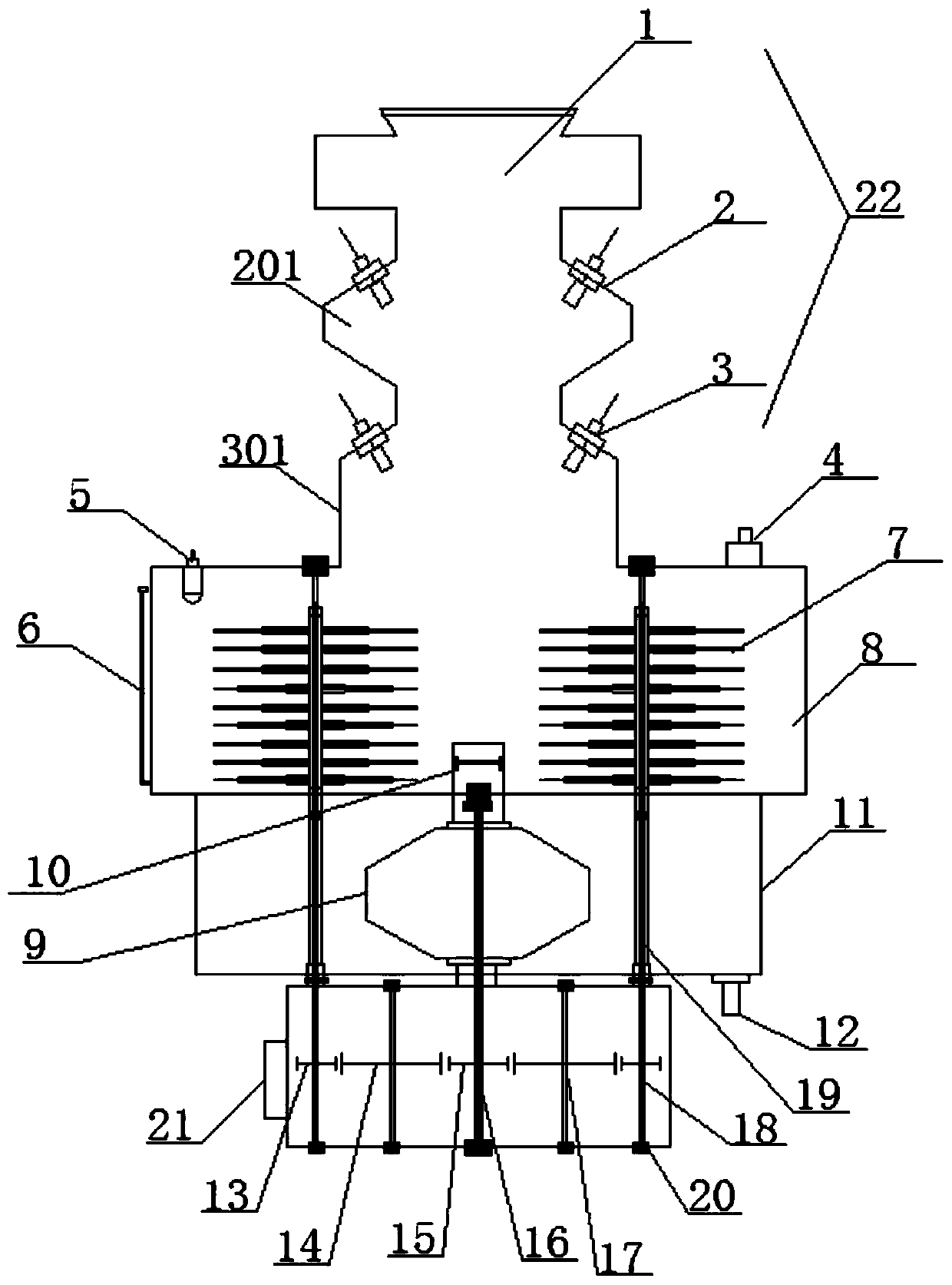

Image

Examples

Embodiment 1

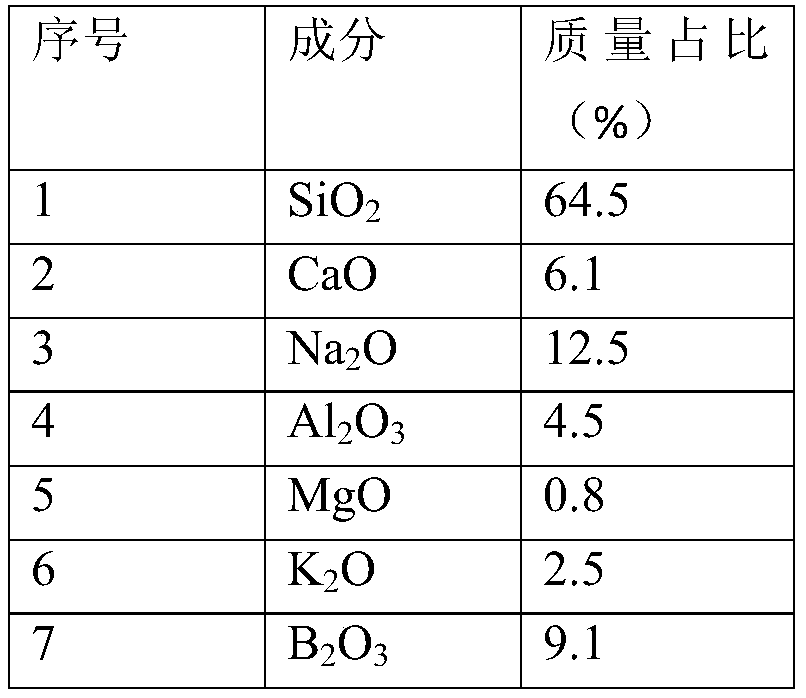

[0054] (1) The ratio of raw materials is shown in Table 1.

[0055] Table 1. Example 1 Raw material ratio

[0056]

[0057] The above glass raw materials are sent to the mixer through each bin with a screw conveyor according to their respective component ratios for mixing, and the fully mixed and uniform proportioning material is transported to the front bin of the kiln via a belt conveyor.

[0058] (2) Furnace melting and homogenization

[0059] The proportioning material is put into the kiln by the automatic feeder. After the proportioning material enters the furnace, it will go through various high temperature stages of 810℃~1100℃, 1100℃~1300℃, and 1300℃~1390℃. From the solid granular raw materials through the sintering reaction, they will finally melt into a transparent glass.

[0060] (3) Forehearth cooling

[0061] After clarification, the molten glass will be cooled down to 1075°C from the initial approximately 1250°C after cooling in each forehearth area, reaching the primary fo...

Embodiment 2

[0079] (1) The ratio of raw materials is shown in Table 2.

[0080] Table 2. Example 2 Raw material ratio

[0081]

[0082] The above glass raw materials are sent to the mixer through each bin with a screw conveyor according to their respective component ratios for mixing, and the fully mixed and uniform proportioning material is conveyed to the front bin of the kiln via a belt conveyor;

[0083] (2) Furnace melting and homogenization

[0084] The proportioning material is put into the kiln by the automatic feeder. After the proportioning material enters the furnace, it will go through various high temperature stages of 810℃~1100℃, 1100℃~1300℃, and 1300℃~1390℃. From the solid granular raw materials through the sintering reaction, they will finally melt into a transparent glass.

[0085] (3) Forehearth cooling

[0086] After clarification, the molten glass drops from the initial about 1250°C to 1075°C through each channel area, and flows uniformly to the drain plate of each channel area....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com