Phosphogypsum cement retarder and preparation method thereof

A technology of cement retarder and phosphogypsum, which is applied in the field of cement retarder, can solve the problems that phosphogypsum cannot be used to prepare cement retarder, and achieve the effect of enhancing the flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

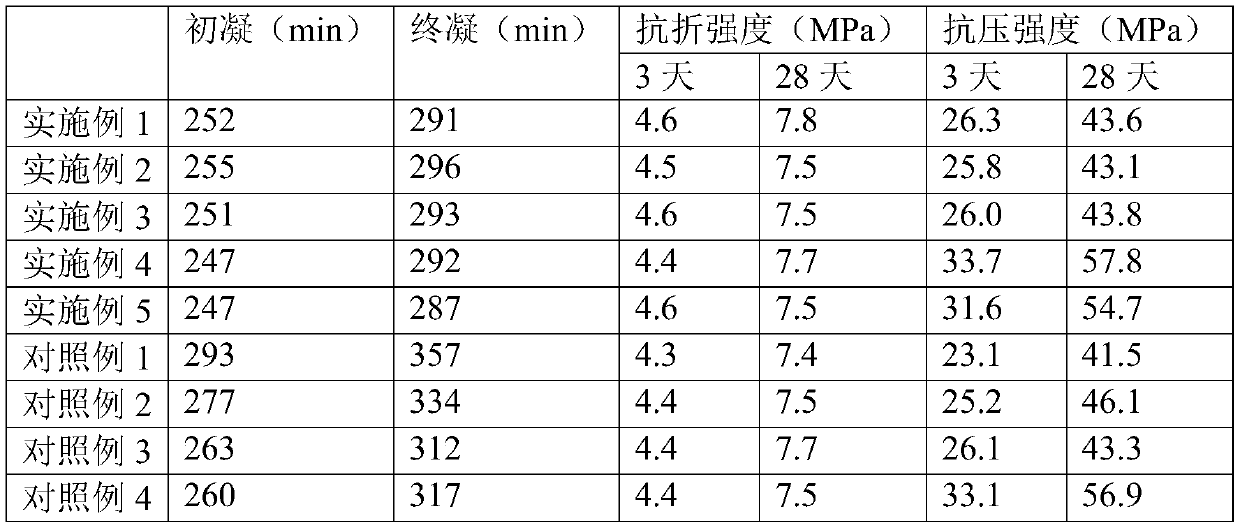

Examples

Embodiment 1

[0021] The phosphogypsum cement retarder is prepared by the following steps:

[0022] Mix 2.0 parts of methyltriethoxysilane, 15 parts of modified diatomaceous earth, and 3 parts of water in a weight ratio for 1 hour to obtain a modifier; then, mix the modifier with 8 parts of lime powder and 50 parts of phosphorus The gypsum is sent to a cyclone dryer for mixing and drying. The drying temperature of the cyclone dryer is 60°C, and then it is collected through a dust bag to obtain a semi-finished product of retarder; finally, the semi-finished product of retarder is aged for 6 hours to obtain a retarder.

Embodiment 2

[0024] The phosphogypsum cement retarder is prepared by the following steps:

[0025] Firstly, 2.5 parts of methyltriethoxysilane, 12 parts of modified diatomaceous earth and 5 parts of water were mixed by weight for 1 hour to obtain the modifier; then, the modifier was mixed with 5 parts of lime powder and 40 parts of water. Part of the phosphogypsum is sent to a cyclone dryer for mixing and drying. The drying temperature of the cyclone dryer is 60°C, and then collected by a dust bag to obtain a semi-finished product of retarder. Finally, the semi-finished product of retarder is aged for 5 hours to obtain a retarder.

Embodiment 3

[0027] The phosphogypsum cement retarder is prepared by the following steps:

[0028] Firstly, 3.0 parts of methyltriethoxysilane, 15 parts of modified diatomaceous earth, and 5 parts of water were mixed by stirring for 1 hour to obtain the modifier; then, the modifier was mixed with 7 parts of lime powder and 60 parts of water. Part of the phosphogypsum is sent to a cyclone dryer for mixing and drying. The drying temperature of the cyclone dryer is 60°C, and then collected by a dust-removing bag to obtain a retarder semi-finished product; finally, the retarder semi-finished product is aged for 7 hours to obtain a retarder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com