Support material for silicon magnesite and preparation method of support material

A mine-used silicon-magnesium technology, which is applied in the field of silicon-magnesium mine support materials and its preparation, can solve problems such as too fast reaction of active magnesium oxide content, product warping and deformation, and lower product quality, so as to achieve light weight, increase Compressive strength, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The first preparation method of the supporting material for the above-mentioned silicon-magnesium mine includes:

[0042] The preparation step of the slurry is to add raw materials other than light-burned magnesia, wood chips, fly ash and glass fiber into the magnesium chloride solution, dissolve and mix evenly, then add light-burned magnesia, stir and mix evenly, and then add sawdust and pulverized coal The mixture of ash is stirred and mixed evenly to obtain a slurry;

[0043] In the slurry mold loading step, first pour part of the slurry into the mold and flatten it so that the thickness of the slurry is 6-8mm, then evenly scatter the glass fibers on the slurry, and then pour part of the slurry and Flatten, so that the thickness of the poured slurry is 6-8mm after being flattened, spread the glass fiber evenly on it again, and then pour in part of the slurry again and spread it, so that the poured slurry is flattened again The final thickness is 6-8mm, and then acco...

Embodiment 1

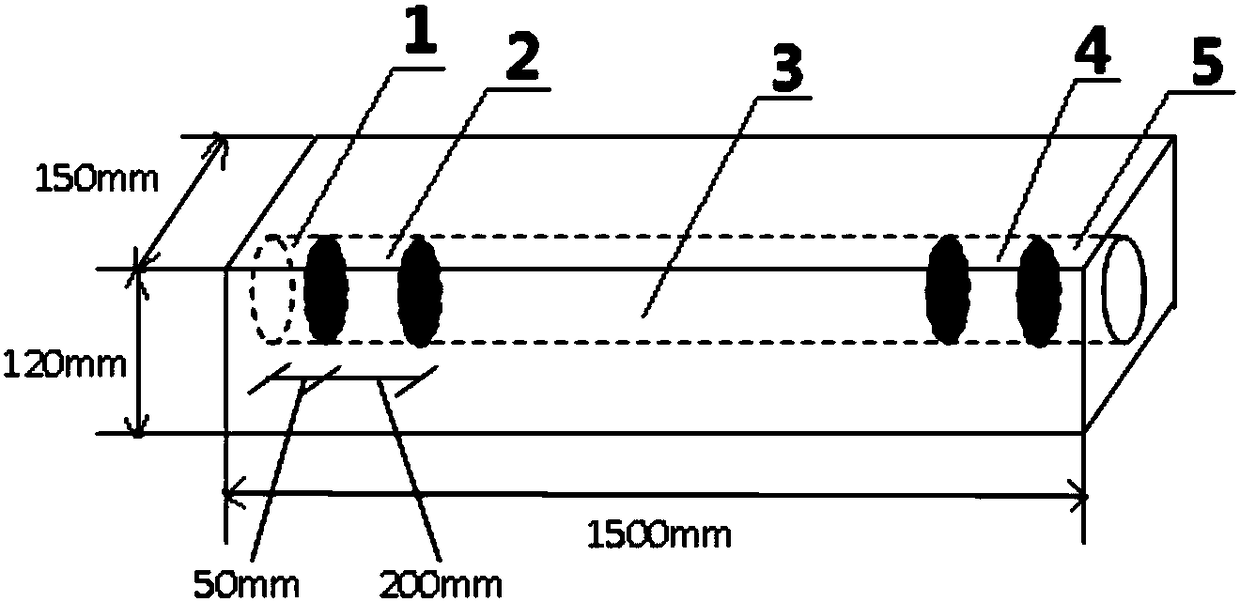

[0059] The structure of the supporting material for silicon-magnesium mines prepared in this embodiment is as follows: the outside is cuboid, and the center of the inside is provided with a hollow structure along the length direction of the cuboid. The hollow structure is a cylindrical hollow structure. The diameter of the cylindrical hollow structure is 72mm. The solid section 4 and the second end hollow section 5, the first end hollow section 1, the first solid section 2, the central hollow section 3, the second solid section 4 and the second end hollow section 5 are sequentially connected, that is, along In the length direction of the cuboid, from one end to the other, the central position of the cuboid, that is, the axis position, is sequentially hollow segment, solid segment, hollow segment, solid segment and hollow segment. The specifications of the cuboid are: 1500mm×150mm×120mm (length×width×height); see figure 1 , the lengths of the first hollow segment at the end an...

Embodiment 2

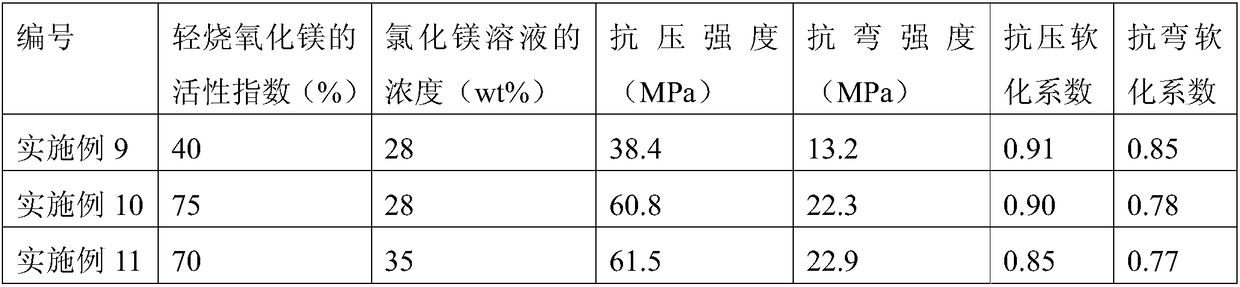

[0069] The structure of the supporting material for silicon-magnesium mine prepared in this embodiment is the same as that of Example 1, except that the raw materials are different from Example 1, and other preparation processes are the same as in Example 1. The raw materials used for the supporting material for silicon-magnesium mine in this embodiment The ratio is:

[0070] 100 parts by weight of light-burned magnesium oxide, 80 parts by weight of magnesium chloride solution, 15 parts by weight of fly ash, 17 parts by weight of wood chips, 0.5 parts by weight of sodium polyphosphate, 0.5 parts by weight of triethanolamine, 7 parts by weight of ferrous sulfate, and 0.4 parts by weight of phosphoric acid Parts, 0.5 parts by weight of tetrabutylammonium chloride, 8 parts by weight of glass fibers. Wherein, the activity index of the light-burned magnesium oxide is 62%, and the concentration of the magnesium chloride solution is 28wt%.

[0071] From a batch of silicon-magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com