Heat insulation roof board and preparation method thereof

A thermal insulation and roof panel technology, which is applied in the field of energy-saving products, can solve the problems of complex preparation methods, poor thermal insulation effect, and poor comprehensive performance of roof thermal insulation panels, and achieve good thermal insulation effect, good heat resistance, and improved The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

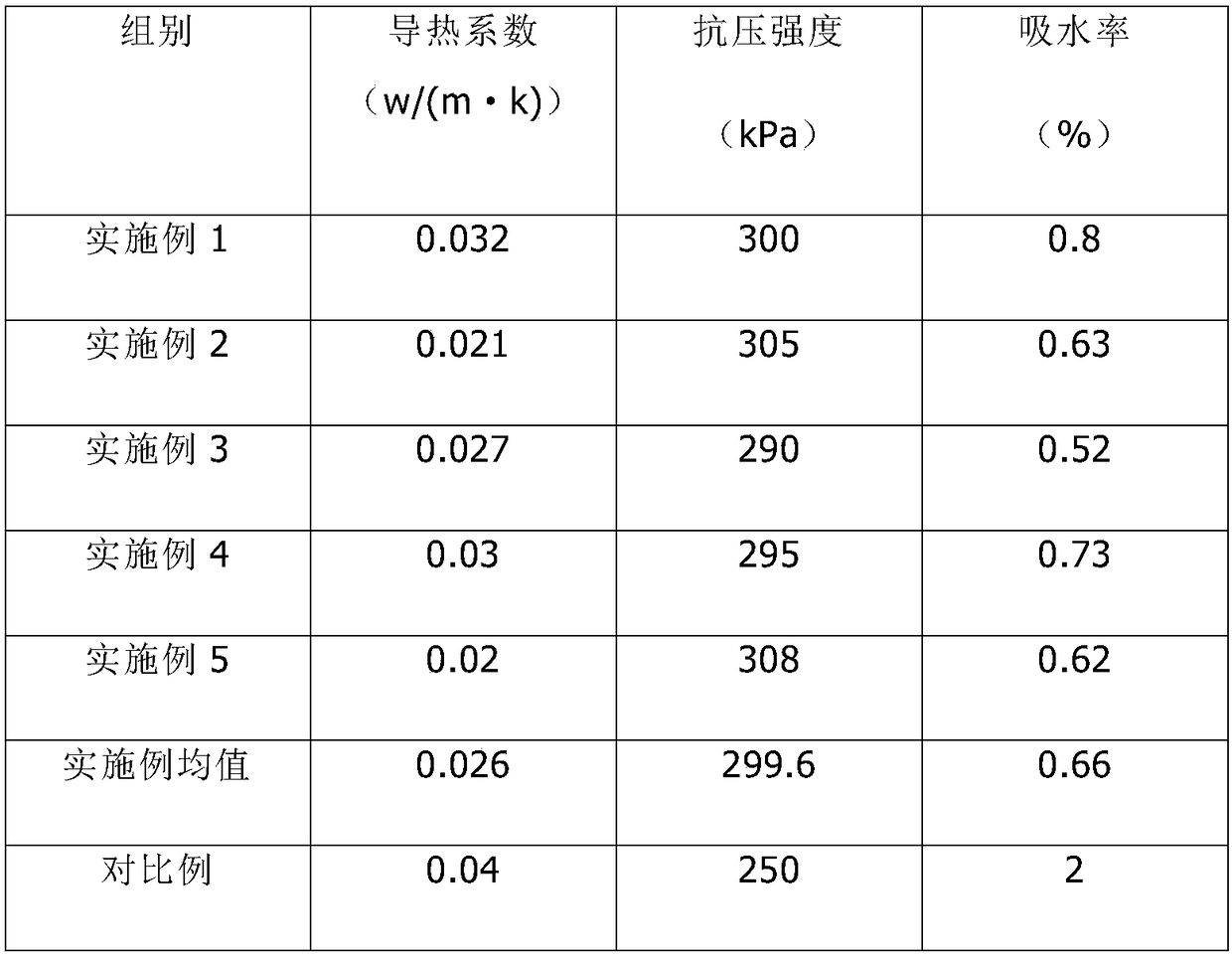

Examples

Embodiment 1

[0031] This embodiment relates to a thermal insulation roof panel, including the following raw materials in parts by weight: 10 parts of floating beads, 10 parts of modified epoxy resin, 11 parts of AES resin, 7 parts of expanded perlite, 15 parts of polystyrene, polyurethane 8 parts, 9 parts of styrene-acrylic emulsion, 4 parts of silica fume, 3 parts of hydroxyethyl cellulose, 2 parts of polypropylene fiber, 2 parts of nano-titanium dioxide, 3 parts of talcum powder, 2 parts of flame retardant, and 2 parts of curing agent.

[0032] Wherein, the preparation method of described modified epoxy resin is as follows:

[0033] (1) Dissolve the epoxy resin and the furyl compound in an anhydrous organic solvent, and react for 8 hours at 70° C. in the presence of a catalyst to obtain a reaction mixture, wherein the epoxy resin has at least 2 Epoxy-based epoxy resin, the furyl compound is a furyl compound having at least one active hydrogen atom in the molecule;

[0034] (2) Remove th...

Embodiment 2

[0046] This embodiment relates to a thermal insulation roof panel, including the following raw materials in parts by weight: 15 parts of floating beads, 20 parts of modified epoxy resin, 19 parts of AES resin, 14 parts of expanded perlite, 25 parts of polystyrene, polyurethane 16 parts, 14 parts of styrene-acrylic emulsion, 7 parts of silica fume, 6 parts of hydroxyethyl cellulose, 5 parts of polypropylene fiber, 4 parts of nano-titanium dioxide, 7 parts of talcum powder, 4 parts of flame retardant, and 3 parts of curing agent.

[0047] Wherein, the preparation method of described modified epoxy resin is as follows:

[0048](1) Dissolve the epoxy resin and the furyl compound in an anhydrous organic solvent, and react for 8 hours at 70° C. in the presence of a catalyst to obtain a reaction mixture, wherein the epoxy resin has at least 2 Epoxy-based epoxy resin, the furyl compound is a furyl compound having at least one active hydrogen atom in the molecule;

[0049] (2) Remove ...

Embodiment 3

[0061] This embodiment relates to a thermal insulation roof panel, including the following raw materials in parts by weight: 11 parts of floating beads, 12 parts of modified epoxy resin, 14 parts of AES resin, 9 parts of expanded perlite, 18 parts of polystyrene, polyurethane 10 parts, 10 parts of styrene-acrylic emulsion, 5 parts of silica fume, 4 parts of hydroxyethyl cellulose, 3 parts of polypropylene fiber, 2.2 parts of nano-titanium dioxide, 4 parts of talcum powder, 2.7 parts of flame retardant, and 2.4 parts of curing agent.

[0062] Wherein, the preparation method of described modified epoxy resin is as follows:

[0063] (1) Dissolve the epoxy resin and the furyl compound in an anhydrous organic solvent, and react for 8 hours at 70° C. in the presence of a catalyst to obtain a reaction mixture, wherein the epoxy resin has at least 2 Epoxy-based epoxy resin, the furyl compound is a furyl compound having at least one active hydrogen atom in the molecule;

[0064] (2) R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com