Alkali-activated grouting material

A technology of grouting material and alkali excitation, which is applied in the field of grouting material, can solve the problems of slowing down the reaction speed, blocking the reaction pathway of active ions, and the inability to proceed the reaction, etc., and achieve the effect of improving the flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

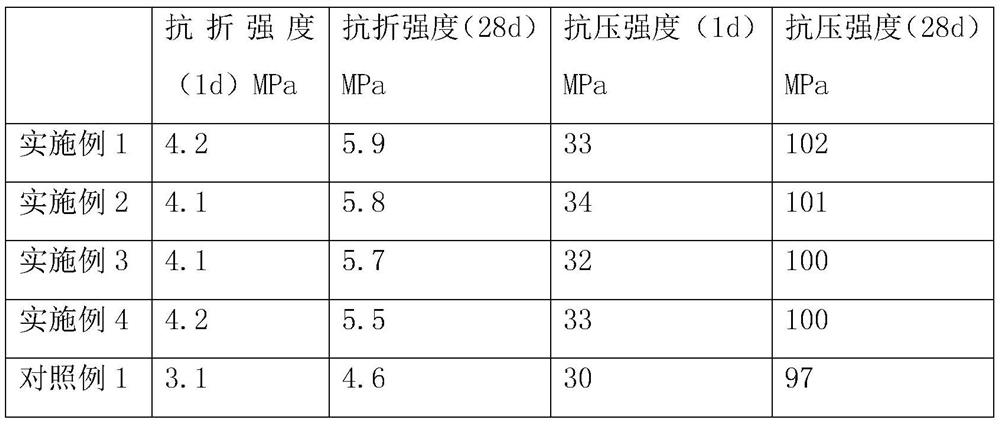

Examples

Embodiment 1

[0014] An alkali-activated grouting material, comprising the following raw materials in parts by weight: 50 parts of slag powder, 35 parts of water glass, 150 parts of high-iron sulfoaluminate cement, 25 parts of sodium bentonite, 25 parts of lithium carbonate, 15 parts of citric acid, 15 parts of graphene oxide, 40 parts of sodium hydroxide, 20 parts of sodium alginate, 30 parts of silicon dioxide.

[0015] High iron sulfoaluminate cement contains ferric oxide, the content is 7%.

Embodiment 2

[0017] An alkali-activated grouting material, comprising the following raw materials in parts by weight: 40 parts of slag powder, 30 parts of water glass, 100 parts of high-iron sulfoaluminate cement, 20 parts of sodium bentonite, 20 parts of lithium carbonate, 10 parts of citric acid, 10 parts of graphene oxide, 20 parts of sodium hydroxide, 10 parts of sodium alginate, 20 parts of silicon dioxide.

[0018] High iron sulfoaluminate cement contains ferric oxide, the content is 6%.

Embodiment 3

[0020] An alkali-activated grouting material, comprising the following raw materials in parts by weight: 60 parts of slag powder, 40 parts of water glass, 200 parts of high-iron sulfoaluminate cement, 30 parts of sodium bentonite, 30 parts of lithium carbonate, 20 parts of citric acid, 20 parts of graphene oxide, 60 parts of sodium hydroxide, 30 parts of sodium alginate, and 40 parts of silicon dioxide.

[0021] High iron sulfoaluminate cement contains ferric oxide, the content is 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com