TiNx-Ti3SiC2 composite material and preparation method of TiNx-Ti3SiC2 composite material

A technology of composite materials and raw materials, applied in the field of composite materials, can solve problems such as low strength, poor wear resistance, and low material hardness, and achieve the effects of improving friction and wear performance, self-lubricating performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

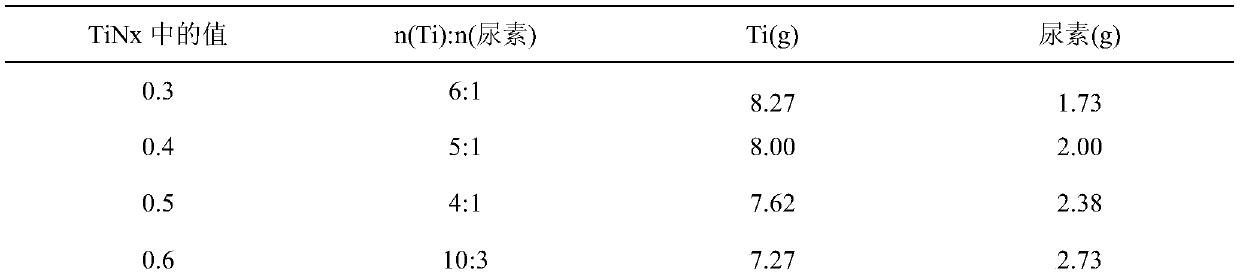

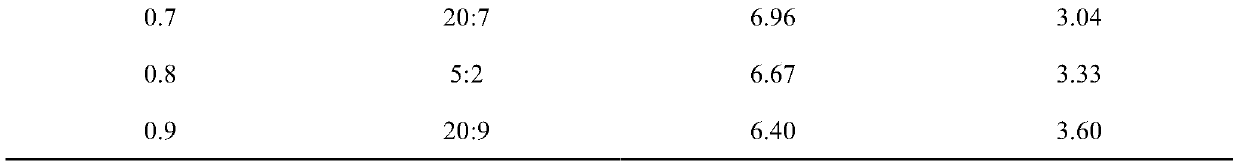

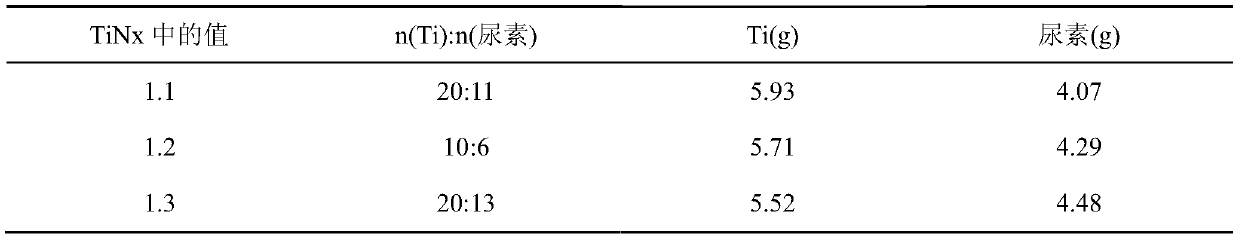

[0044] First, prepare TiN 0.3 powder. Weigh the Ti powder and urea according to the molar ratio of n(Ti):n(urea)=6:1 in the Ar gas environment of the glove box, and put the weighed raw materials into the WC hard disk in the Ar gas environment of the glove box. Then, put WC cemented carbide balls in the ball mill jar (the diameter of the large ball is 8mm; the diameter of the small ball is 5mm; the mass ratio of the large and small balls is 7:3). The mass ratio of ball to material is 20:1. And add dispersant in raw material powder, described dispersant is industrial ethanol (purity is analytical grade), and dispersant addition is to add 0.4mL in every 100g mixed powder. Then, it is ball milled at a uniform speed on a ball mill. The speed of the ball mill is 400r / min; the ball milling time is 50h; each revolution is 60min, stop for 20min to dissipate heat; and run alternately forward and reverse to produce TiN finer than 150nm 0.3 powder.

[0045] Second, the preparation of...

Embodiment 2

[0049] First, prepare TiN 0.3 powder. In the Ar gas environment of the glove box, the Ti powder and urea are weighed according to the molar ratio of n(Ti):n(urea)=6:1, and the weighed raw materials are put into the WC in the Ar gas environment of the glove box. Carbide ball milling jar; then, put WC carbide balls (large ball diameter 8mm; small ball diameter 5mm; mass ratio of large and small balls is 7:3) in the ball mill jar. The mass ratio of ball to material is 20:1. And add dispersant in raw material powder, described dispersant is industrial ethanol (purity is analytical grade), and dispersant addition is to add 0.4mL in every 100g mixed powder. Then, it is ball milled at a uniform speed on a ball mill. The speed of the ball mill is 400r / min; the ball milling time is 50h; each revolution is 60min, stop for 20min to dissipate heat; and run alternately forward and reverse to produce TiN finer than 150nm 0.3 powder.

[0050] Second, the preparation of TiN 0.3 -Ti 3 SiC...

Embodiment 3

[0054] First, prepare TiN 0.3 powder. In the Ar gas environment of the glove box, the Ti powder and urea are weighed according to the molar ratio of n(Ti):n(urea)=6:1, and the weighed raw materials are put into the WC in the Ar gas environment of the glove box. Carbide ball milling jar; then, put WC carbide balls (large ball diameter 8mm; small ball diameter 5mm; mass ratio of large and small balls is 7:3) in the ball mill jar. The mass ratio of ball to material is 20:1. And add dispersant in raw material powder, described dispersant is industrial ethanol (purity is analytical grade), and dispersant addition is to add 0.4mL in every 100g mixed powder. Then, it is ball milled at a uniform speed on a ball mill. The speed of the ball mill is 400r / min; the ball milling time is 50h; each revolution is 60min, stop for 20min to dissipate heat; and run alternately forward and reverse to produce TiN finer than 150nm 0.3 powder.

[0055] Second, the preparation of TiN 0.3 -Ti 3 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com